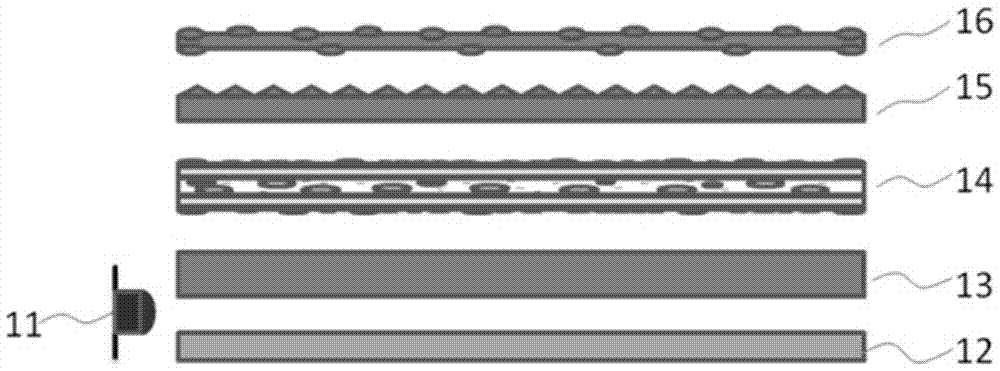

Green quantum dot film and backlight module thereof

A technology of backlight module and quantum dot film, applied in the field of optical film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of LED lamp

[0032] Apply the red phosphor colloid on the top of the blue LED chip through the dispensing equipment so that it completely covers the chip and forms a hemispherical appearance, put it in an oven at 150°C, and take it out after the colloid is cured and fix it on the substrate. Then, the transparent shell is installed on the substrate by the encapsulant to complete the preparation of the LED lamp.

Embodiment 2

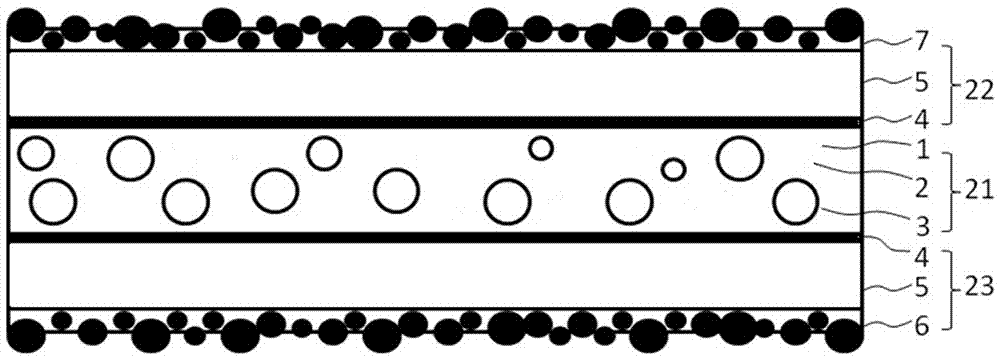

[0033] Example 2 Preparation of green quantum dot film

[0034] First, the front of the PET film is subjected to vacuum evaporation treatment so that the surface forms a barrier layer with good water and oxygen resistance properties (thickness is about 2 μm to 5 μm), and the back of the base film after vacuum evaporation treatment is then coated. .

[0035] The green quantum dots in the quantum dot layer are 0.6-1.0 parts by mass, and the proportions of other main components and corresponding parts by weight are as follows:

[0036] Resin: 35-45 parts by mass;

[0037] Monomer: 45-55 parts by mass;

[0038] Photoinitiator: 1 to 3 parts by mass;

[0039] Diffusing particles: 1 to 3 parts by mass;

[0040] Other additives: 2-5 parts by mass.

[0041] The preparation method comprises the following steps:

[0042] ①Configuration of UV-curable glue: Mix resin, monomer, photoinitiator, diffusion particles, and additives in proportion, heat slowly, keep the temperature within 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com