Reaction tank for wafer etching

A reaction tank and wafer technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high etching rate at the bottom of the wafer and low etching rate at the top of the wafer, and achieve the goal of improving the surface quality of the wafer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided for more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

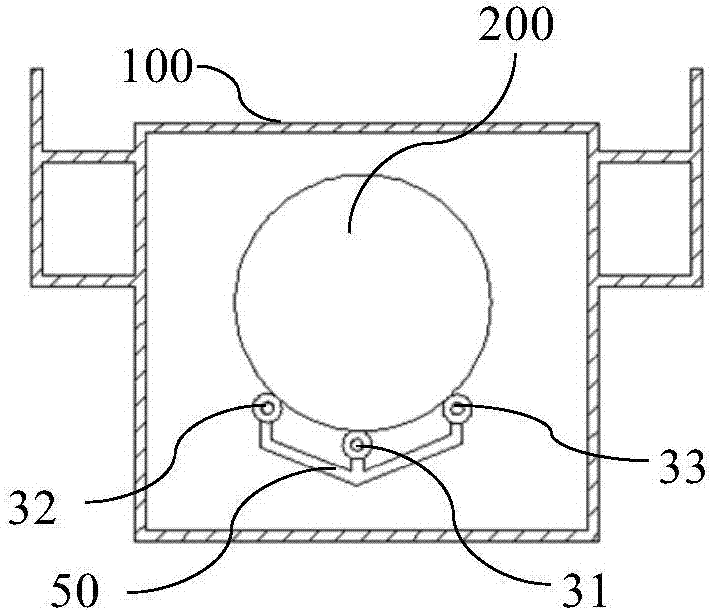

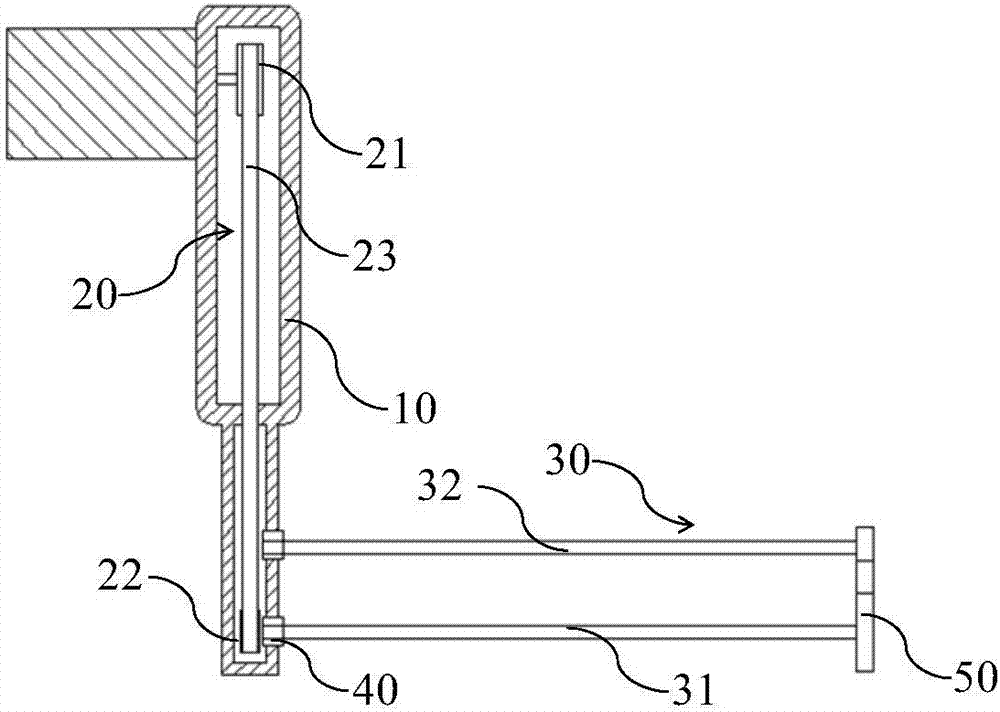

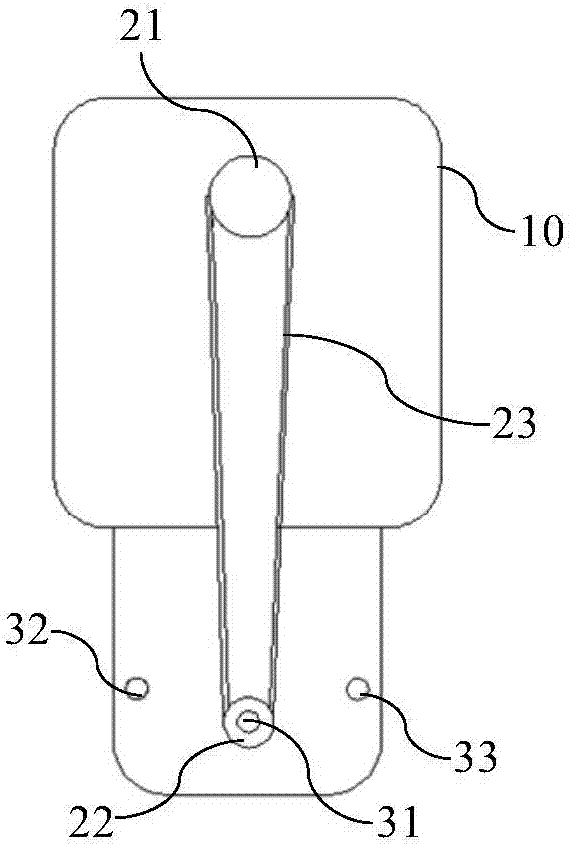

[0027] figure 1 It is a schematic diagram of the front structure of the internal structure of the embodiment of the present invention. figure 2 for figure 1 The side structural cross-sectional view of the internal structure of the embodiment. image 3 for figure 1 A schematic diagram of the internal structure of the lifting arm of the embodiment. As shown in the figure, the reaction tank for wafer etching in this embodiment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com