Carbonitrone/silver carbonate composite nanomaterial, its preparation method and its application

A technology of composite nanomaterials and silver carbonate, applied in the field of nanomaterials, can solve problems such as unsatisfactory photocatalytic stability, and achieve the effects of simple and easy-to-control production process, improved degradation speed, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

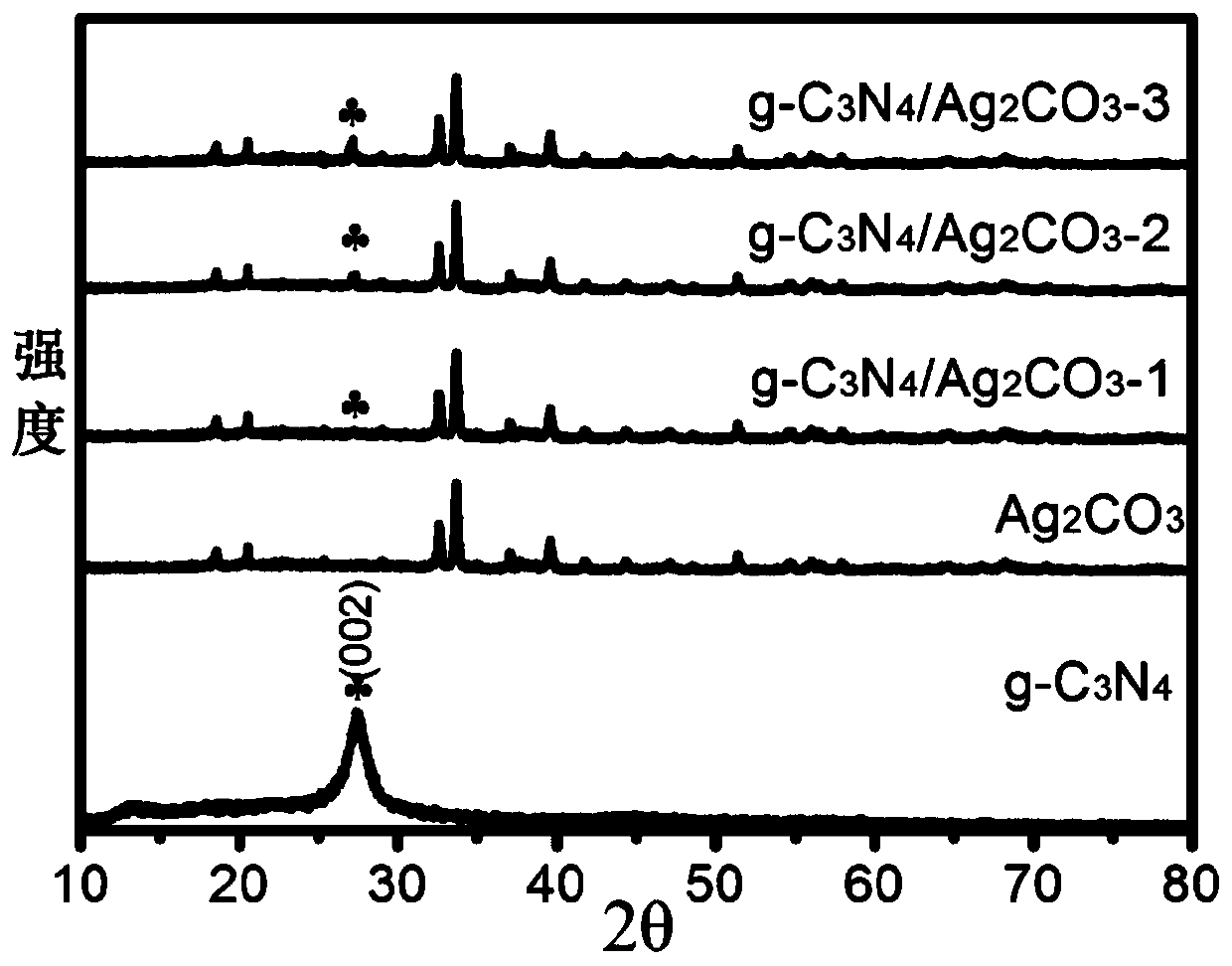

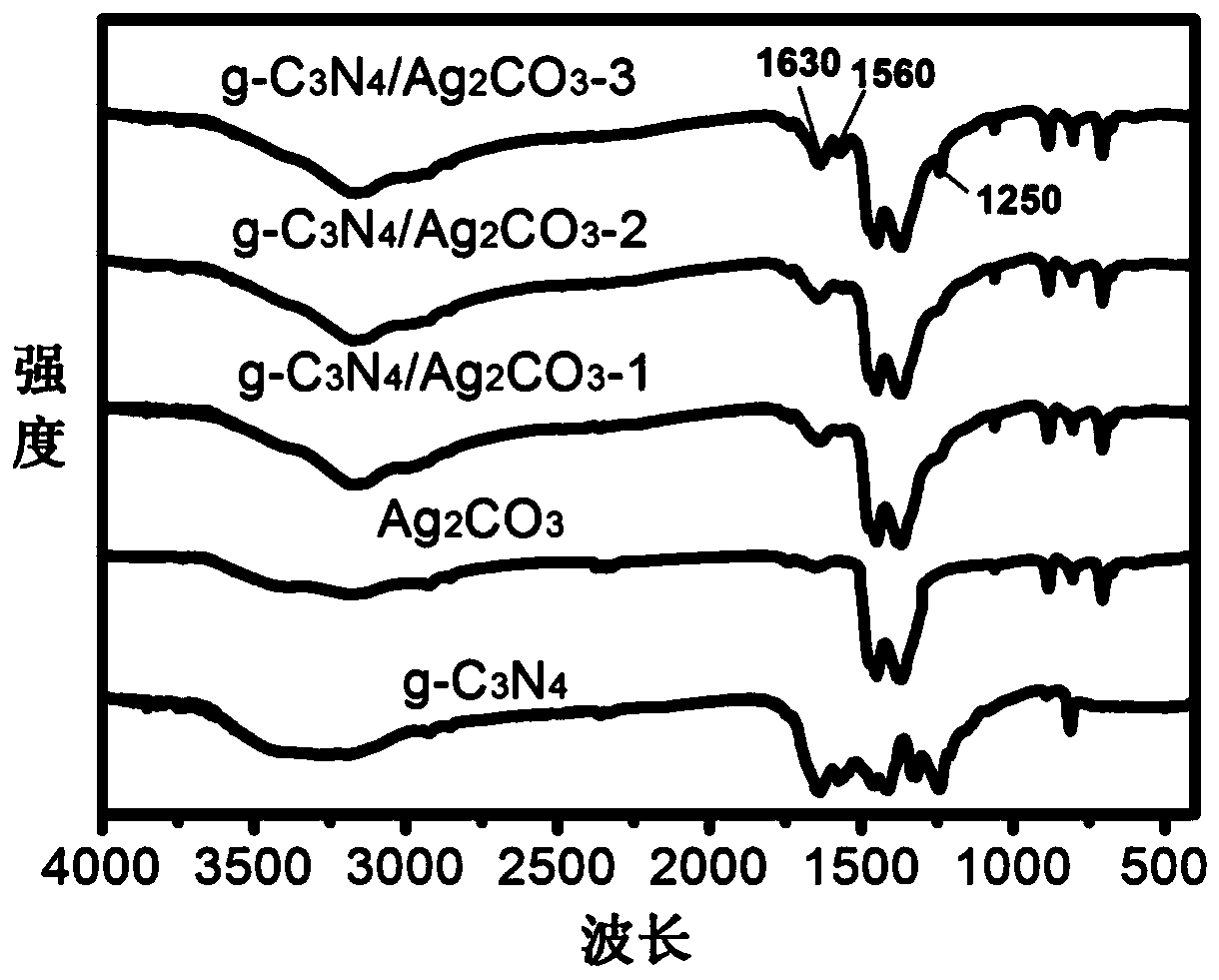

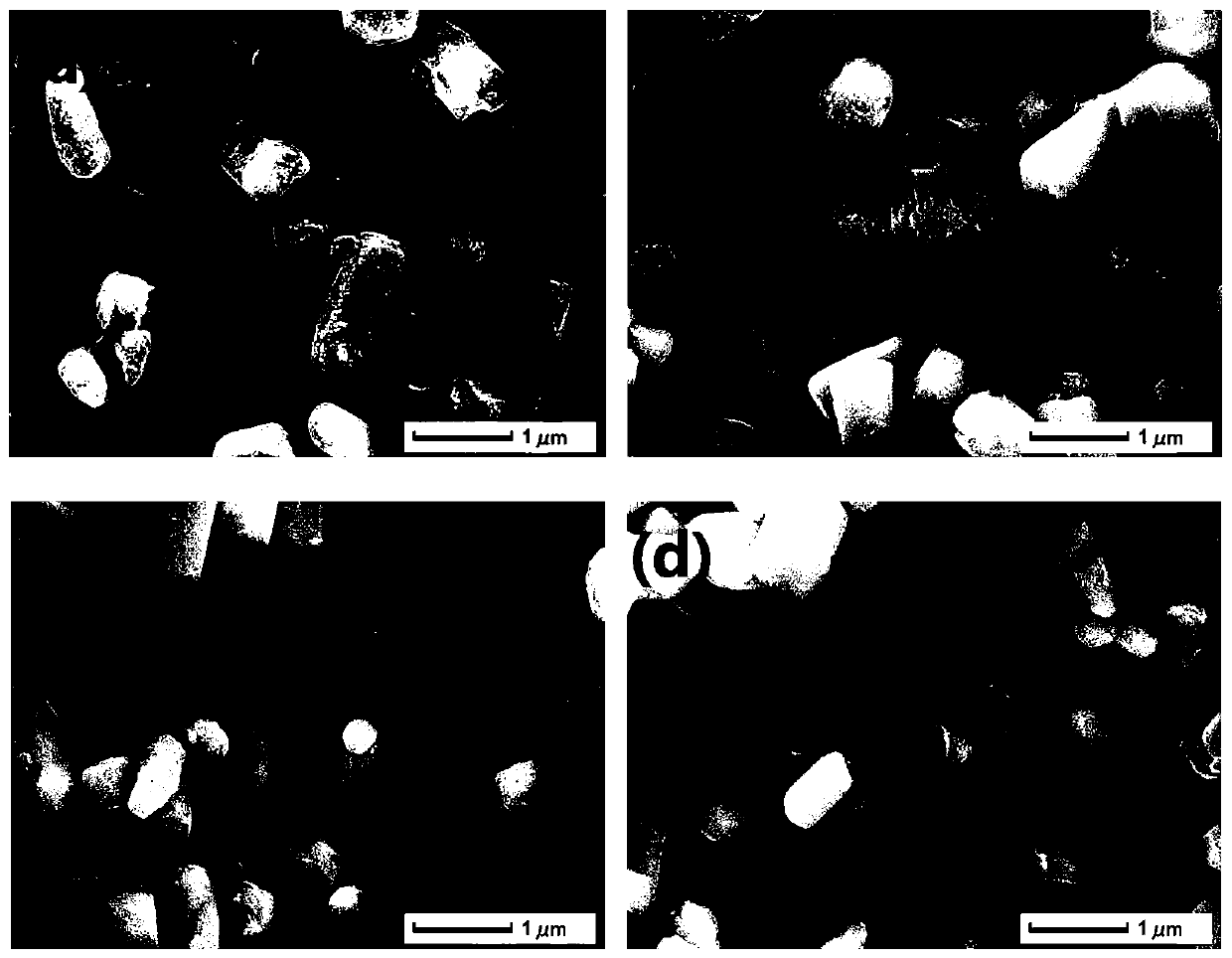

[0024] Step (1): Weigh 10 g of a mixture of urea and melamine (molar ratio 1:1) into a crucible, and then bake in a muffle furnace at 580° C. for 1 h with a heating rate of 5 / min. The synthesized yellow powder was washed several times with deionized water and absolute ethanol, and finally dried under vacuum at 60°C for 12 hours to obtain g-C 3 N 4 Lamellar structure;

[0025] Step (2), under room temperature conditions, the g-C prepared by 2mg (1) 3 N 4 Dissolve in 20mL deionized water and ultrasonically disperse for at least 1h, then add 2mmol AgNO 3 Disperse in 20mL deionized water, and gradually add it dropwise to the above g-C after fully dissolving 3 N 4 The solution was stirred well, and finally 20mL Na 2 CO 3 10H 2 O (0.05M) solution was added dropwise to the above solution and fully stirred for 1 hour, then washed and centrifuged with deionized water and ethanol several times, and dried at 60°C to obtain a 2%-carbanitroene / silver carbonate sample, which was def...

Embodiment 2

[0027] Step (1): Add 10 g of urea and melamine mixture (molar ratio 1:0.5) weighed into the crucible, and then bake in a muffle furnace at 400° C. for 4 h with a heating rate of 5 / min. The synthesized yellow powder was washed several times with deionized water and absolute ethanol, and finally dried under vacuum at 60°C for 12 hours to obtain g-C 3 N 4 Lamellar structure;

[0028] Step (2), under room temperature conditions, the g-C prepared by 4mg (1) 3 N 4 Dissolve in 20mL deionized water and ultrasonically disperse for at least 1h, then add 2mmol AgNO 3 Disperse in 20mL deionized water, and gradually add it dropwise to the above g-C after fully dissolving 3 N 4 The solution was stirred well, and finally 20mL NaHCO 3 (0.05M) solution was added dropwise to the above solution and fully stirred for 1 hour, then washed and centrifuged with deionized water and ethanol several times, and dried at 60°C to obtain a 4%-carbanitroene / silver carbonate sample, which was defined as...

Embodiment 3

[0030] Step (1): Add 10 g of the urea-melamine mixture (molar ratio 1:6) weighed into the crucible, and then bake it in a muffle furnace at 650° C. for 0.5 h with a heating rate of 5 / min. The synthesized yellow powder was washed several times with deionized water and absolute ethanol, and finally dried under vacuum at 60°C for 12 hours to obtain g-C 3 N 4 Lamellar structure;

[0031] Step (2), under room temperature conditions, the g-C prepared by 6mg (1) 3 N 4 Dissolve in 20mL deionized water and ultrasonically disperse for at least 1h, then add 2mmol AgNO 3 Disperse in 20mL deionized water, and gradually add it dropwise to the above g-C after fully dissolving 3 N 4 The solution was stirred well, and finally 20mL K 2 CO 3 (0.05M) solution was added dropwise to the above solution and fully stirred for 1 hour, then washed and centrifuged with deionized water and ethanol several times, and dried at 60°C to obtain a 6%-carbanitroene / silver carbonate sample, which was defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com