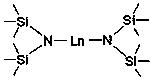

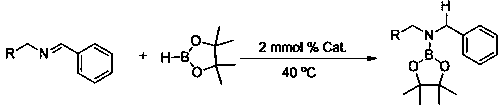

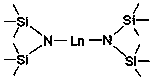

Application of Disilazide Rare Earth Complex in Catalytic Hydroboration of Imine and Borane

A rare earth complex, catalytic imine technology, applied in catalytic reactions, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Good yield and other problems, to achieve the effects of easy product post-processing, fast reaction speed, and reduced catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: Yb[N(SiMe 3 ) 2 ] 2 Catalytic synthesis of amino borates from benzylidene aniline and pinacol borane

[0025] Under an inert gas atmosphere, add benzylidene aniline (90.62 mg, 0.5 mmol) to the reaction flask after dehydration and deoxygenation treatment, and then add Yb[N(SiMe 3 ) 2 ] 2 Acetonitrile solution (0.1 mL, 0.01mmol), then add pinacol borane (63.99mg, 0.5mmol) with a pipette gun, react at 40°C for 3h, then add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 88%. NMR data of the product: 1 H NMR (400 MHz, CDCl3) δ 7.33 – 7.17 (m, 10H, ArH), 4.73 (s, 2H, NCH 2 ), 1.33 (s, 12H, CH 3 ).

Embodiment 2

[0026] Embodiment two: Eu[N(SiMe 3 ) 2 ] 2 Catalytic synthesis of amino borates from benzylidene aniline and pinacol borane

[0027] Under an inert gas atmosphere, add benzylidene aniline (90.62 mg, 0.5 mmol) to the reaction flask after dehydration and deoxygenation treatment, and then add Eu[N(SiMe 3 ) 2 ] 2 Acetonitrile solution (0.1 mL, 0.01mmol), then add pinacol borane (63.99mg, 0.5mmol) with a pipette gun, react at 40°C for 3h, then add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 82%. NMR data of the product: 1 H NMR (400 MHz, CDCl3) δ 7.33 – 7.17 (m, 10H, ArH), 4.73 (s, 2H, NCH 2 ), 1.33 (s, 12H, CH 3 ).

Embodiment 3

[0028] Embodiment three: Sm[N(SiMe 3 ) 2 ] 2 Catalytic synthesis of amino borates from benzylidene aniline and pinacol borane

[0029] Under an inert gas atmosphere, add benzylidene aniline (90.62 mg, 0.5 mmol) to the reaction flask after dehydration and deoxygenation treatment, and then add Eu[N(SiMe 3 ) 2 ] 2 Acetonitrile solution (0.1 mL, 0.01mmol), then add pinacol borane (63.99mg, 0.5mmol) with a pipette gun, react at 40°C for 3h, then add CDCl 3 Dubbed into a solution. Calculated 1 H spectrum yield was 80%. NMR data of the product: 1 H NMR (400 MHz, CDCl3) δ 7.33 – 7.17 (m, 10H, ArH), 4.73 (s, 2H, NCH 2 ), 1.33 (s, 12H, CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com