A method for continuously repairing soil in situ by screw press

An in-situ repairing soil technology, applied in the field of soil remediation, can solve the problems of difficulty in meeting the requirements of rapid urban soil remediation, short environmental impact remediation period, limited application range, etc., to achieve good application prospects, rapid and continuous remediation, and solve soil The effect of heavy metal pollution on the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

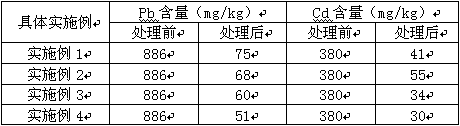

Embodiment 1

[0018] A method for continuously repairing soil in situ by screw press filtration, comprising the following steps:

[0019] The soil is put into the co-rotating screw machine, mixed and refined at a speed of 120rpm to obtain a refined soil. Composed of meshing threaded elements with an angle of 60° and four sets of reverse 56 / 56 conveying threaded elements, in the shearing and thinning section, the thinned soil is evenly dispersed along the direction of screw rotation, forming a sheet-shaped orientation, and gradually conveyed forward ; In the pickling section, a hydrochloric acid solution with a concentration of 1mol / L is added to the refined soil, wherein the volume ratio of the refined soil to the acidic solution is 1:4, and the pickling section is composed of four sets of inclined angles: 45° engaging threaded elements, four sets of engaging threaded elements with an inclination angle of 60°, and four sets of reversed 45° engaging threaded elements to obtain a mixed system...

Embodiment 2

[0021] A method for continuously repairing soil in situ by screw press filtration, comprising the following steps:

[0022] The soil is put into the co-meshing screw machine, mixed and refined at a speed of 120rpm to obtain a refined soil, and the shearing and refining section is composed of two sets of 56 / 56 conveying screw elements, two sets of toothed discs, four sets of Composed of meshing thread elements with an inclination angle of 60° and four sets of reverse 56 / 56 conveying thread elements, in the shearing and thinning section, the thinned soil is evenly dispersed along the direction of screw rotation to form a sheet-shaped orientation and gradually move forward Transportation; in the pickling section, add a hydrochloric acid solution with a concentration of 2mol / L to the refined soil, wherein the volume ratio of the refined soil to the acidic solution is 1:5, and the pickling section is composed of four groups of bevels Composed of 45° engaging threaded elements, four...

Embodiment 3

[0024] A method for continuously repairing soil in situ by screw press filtration, comprising the following steps:

[0025]The soil is put into the co-meshing screw machine, mixed and refined at a speed of 120rpm to obtain a refined soil, and the shearing and refining section is composed of two sets of 56 / 56 conveying screw elements, two sets of toothed discs, four sets of Composed of meshing thread elements with an inclination angle of 60° and four sets of reverse 56 / 56 conveying thread elements, in the shearing and thinning section, the thinned soil is evenly dispersed along the direction of screw rotation to form a sheet-shaped orientation and gradually move forward Transportation; in the pickling section, add a hydrochloric acid solution with a concentration of 0.5mol / L to the refined soil, wherein the volume ratio of the refined soil to the acidic solution is 1:6, and the pickling section is composed of four groups of inclined The filter press section of the meshing threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com