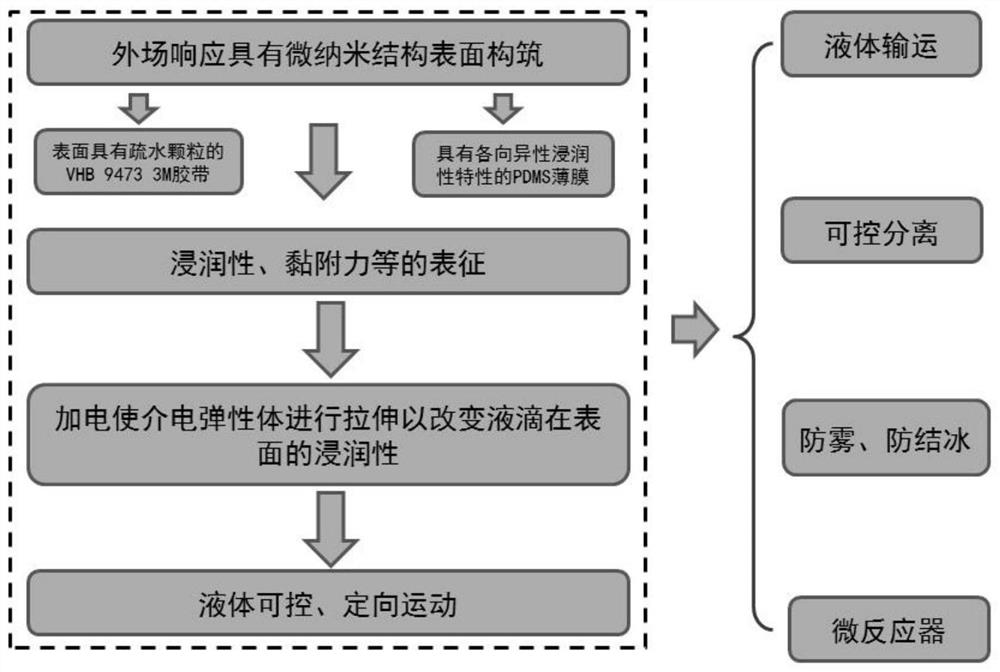

Electric Field Responsive Elastomer Microstructure Surface Liquid Transport Device and Preparation Method

A technology of electric field response and structured surface, applied in applications, flat products, and other household appliances, can solve the problems of poor controllability and flexibility, and achieve the effect of simple operation, fast response, and fast in-situ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

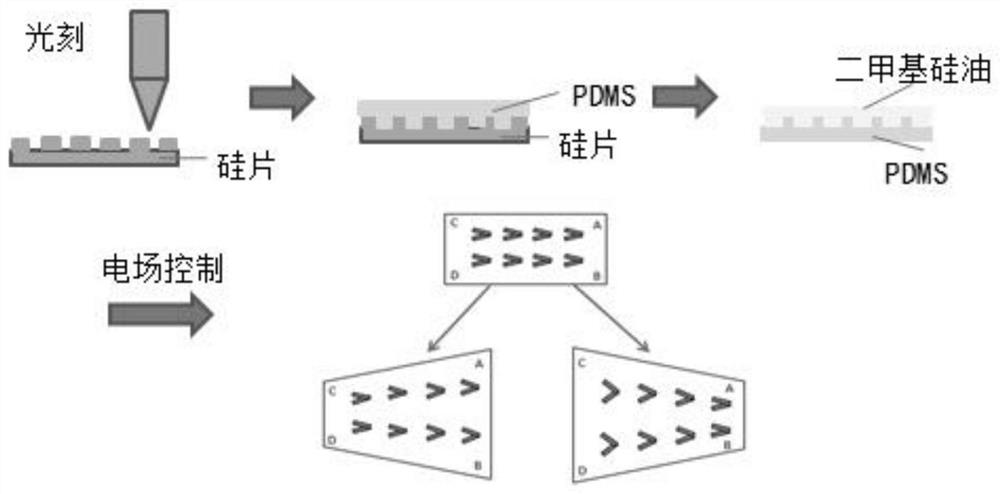

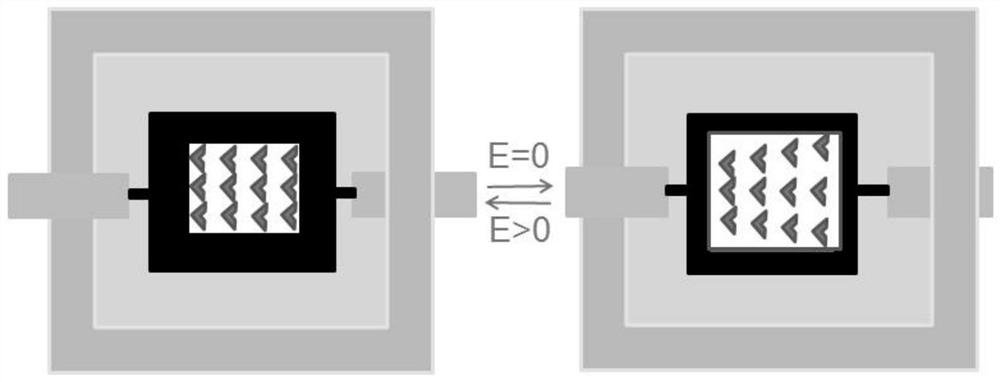

[0028] A PDMS film with anisotropic wetting properties includes a substrate and the micro-nano material, the substrate is an elastomer with electrical response properties, and the specific substrate is Dow Corning 184 polydimethylsiloxane.

[0029] A method for preparing an anisotropic micro-nano structured surface material, comprising the following steps:

[0030] Step 1: Coat a layer of photoresist on the silicon wafer, use photolithography to carve the required "V" structure on the silicon wafer, and make different horizontal and vertical spacing;

[0031] Step 2: Select an elastomer with electrical response properties and mix it evenly with a ratio of 10:1 between the main agent and the curing agent;

[0032] Step 3: Remove air bubbles by vacuuming, place in an electric blast drying oven at 80°C-120°C for 1 hour, and then solidify and form;

[0033] Step 4: Take it out to cool down, and remove the PDMS film from the silicon wafer to obtain a structured PDMS film.

[0034...

Embodiment 2

[0041] A PDMS film with anisotropic wetting properties, including a substrate and the micro-nano material, the substrate is an elastomer with electrical response properties, and the substrate is selected from Dow Corning 184 polydimethylsiloxane, acrylate elastomer, polyurethane Any type of elastomer.

[0042] A method for preparing an anisotropic micro-nano structured surface material, comprising the following steps:

[0043] Step 1: Carve out the required asymmetric structure on the silicon wafer by designing the template, and make different horizontal and vertical spacings. The asymmetric structure is a trapezoidal prism;

[0044] Step 2: Select an elastomer with electrical response properties and mix it uniformly at a ratio of 10:1;

[0045]Step 3: Remove air bubbles by vacuuming, place in an electric blast drying oven at 80°C for 45 minutes, and then solidify and form;

[0046] Step 4: Take it out to cool down, and remove the PDMS film from the silicon wafer to obtain a...

Embodiment 3

[0054] A PDMS film with anisotropic wetting properties, including a substrate and the micro-nano material, the substrate is an elastomer with electrical response properties, and the substrate is selected from Dow Corning 184 polydimethylsiloxane, acrylate elastomer, polyurethane Any type of elastomer.

[0055] A method for preparing an anisotropic micro-nano structured surface material, comprising the following steps:

[0056] Step 1: Carve out the required asymmetric structure on the silicon wafer by designing the template, and make different horizontal and vertical spacings. The asymmetric structure is a trapezoidal prism;

[0057] Step 2: Select an elastomer with electrical response properties and mix it uniformly at a ratio of 10:1;

[0058] Step 3: Remove air bubbles by vacuuming, place in an electric blast drying oven at 80°C for 1 hour, and then solidify and form;

[0059] Step 4: Take it out to cool down, and remove the PDMS film from the silicon wafer to obtain a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com