Anti-winding guide plate locating method and rolling mill

The technology of an anti-winding guide plate and a positioning method, which is applied in the field of steel rolling, can solve the problems of complex adjustment method and structure, difficult to achieve precise and stable control stroke, etc., and achieve the effects of low working cost, easy maintenance and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the present invention provides a positioning method for an anti-winding guide plate, the method comprising:

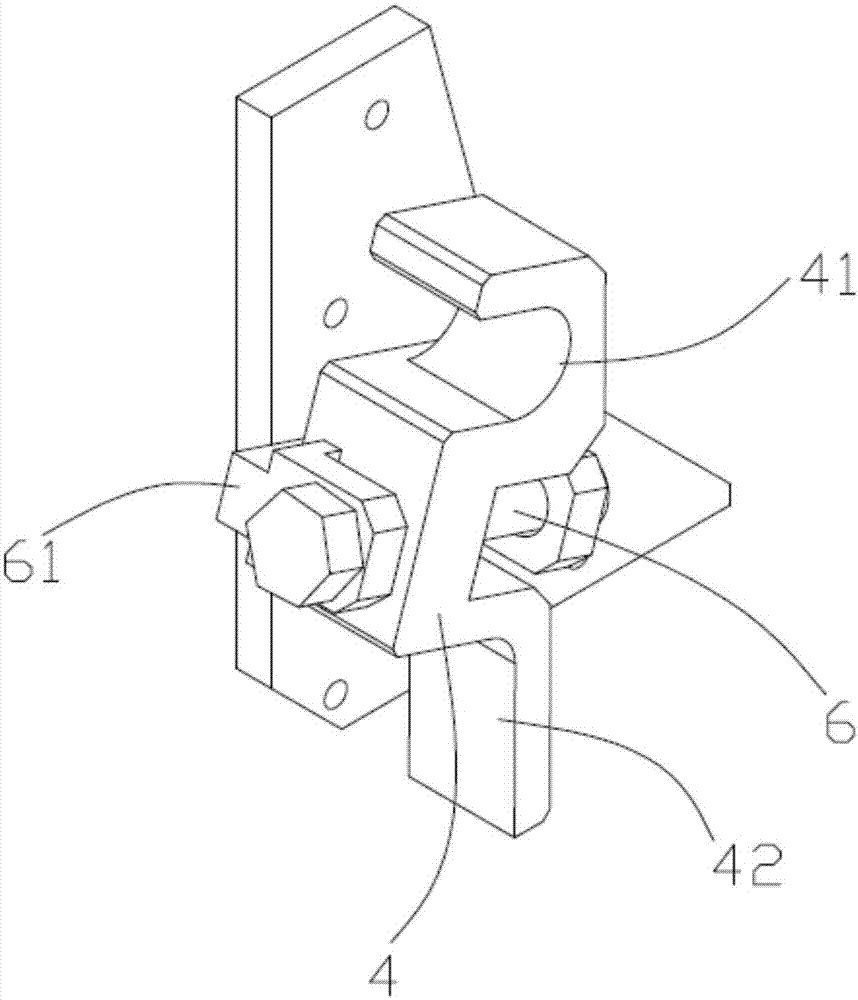

[0035] The first positioning member 4 is arranged on the roll bearing seat 2, and the second positioning member 5 is arranged on the anti-winding guide plate 3. The position of the first positioning member 4 on the bearing seat 2 is adjustable; Before the anti-winding guide plate 3, the position of the first positioning member 4 is marked so that it satisfies: in the process of driving the anti-winding guide plate 3 close to the roll 1, the first positioning member 4 and the second positioning member 5 Cooperate so that the anti-winding guide plate 3 is stopped at the target working position.

[0036] The positioning method of the anti-tangle guide plate provided in this embodiment adopts a simple mechanical positioning method to replace the traditional detection instrument and control system, avoiding the current industry’s conventional relianc...

Embodiment 2

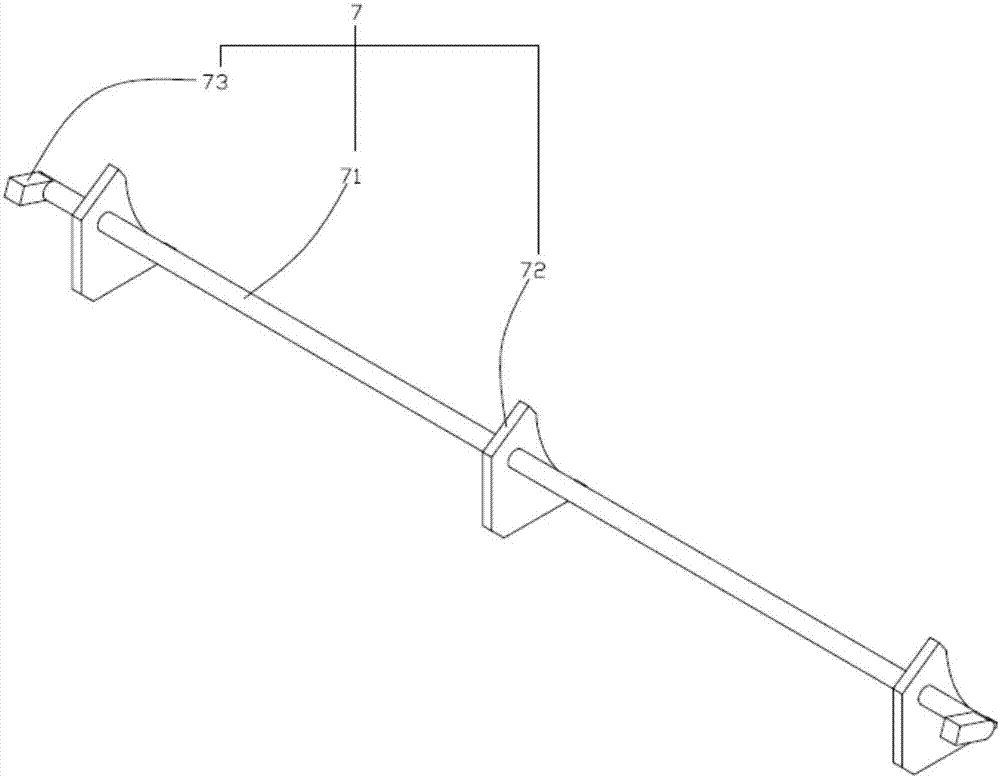

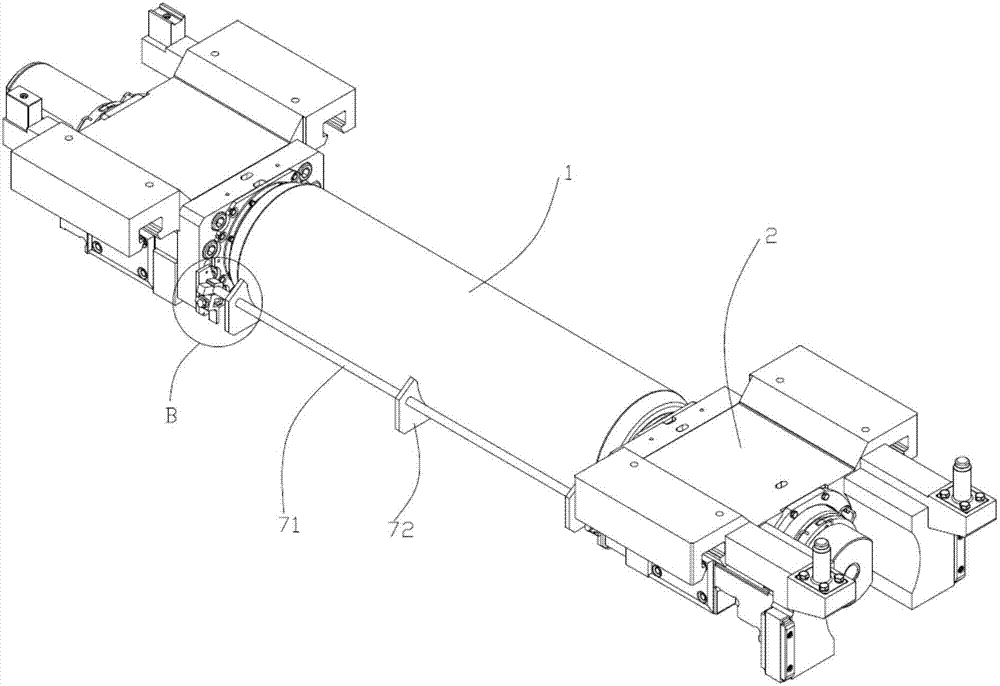

[0056] Such as image 3 and Figure 5 , the embodiment of the present invention relates to a rolling mill, comprising a pair of work rolls 1, at least one of the work rolls 1 is an anti-wrap work roll 1 equipped with an anti-wrap guide plate 3, and the anti-wrap guide plate 3 is connected with a Close to or away from the driving mechanism of the corresponding anti-wrap work roll 1, a first positioning member 4 is provided on the bearing seat 2 of the anti-wrap work roll 1, and a second positioning member 4 is provided on the anti-wrap guide plate 3. Component 5, the position of the first positioning component 4 on the bearing seat 2 is adjustable; the rolling mill is also equipped with a calibration device, which is used to calibrate the position of the first positioning component 4, so that the first positioning The member 4 satisfies: in the process of driving the anti-winding guide plate 3 close to the corresponding anti-winding work roll 1, the first positioning member 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com