Injection molding machine

A technology of injection molding machine and constant temperature box, which is applied in the field of injection molding machine equipment, can solve problems such as heat loss, failure to work normally, and increase production costs, and achieve the effects of preventing pipelines from being blocked, low manufacturing costs, and protecting molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

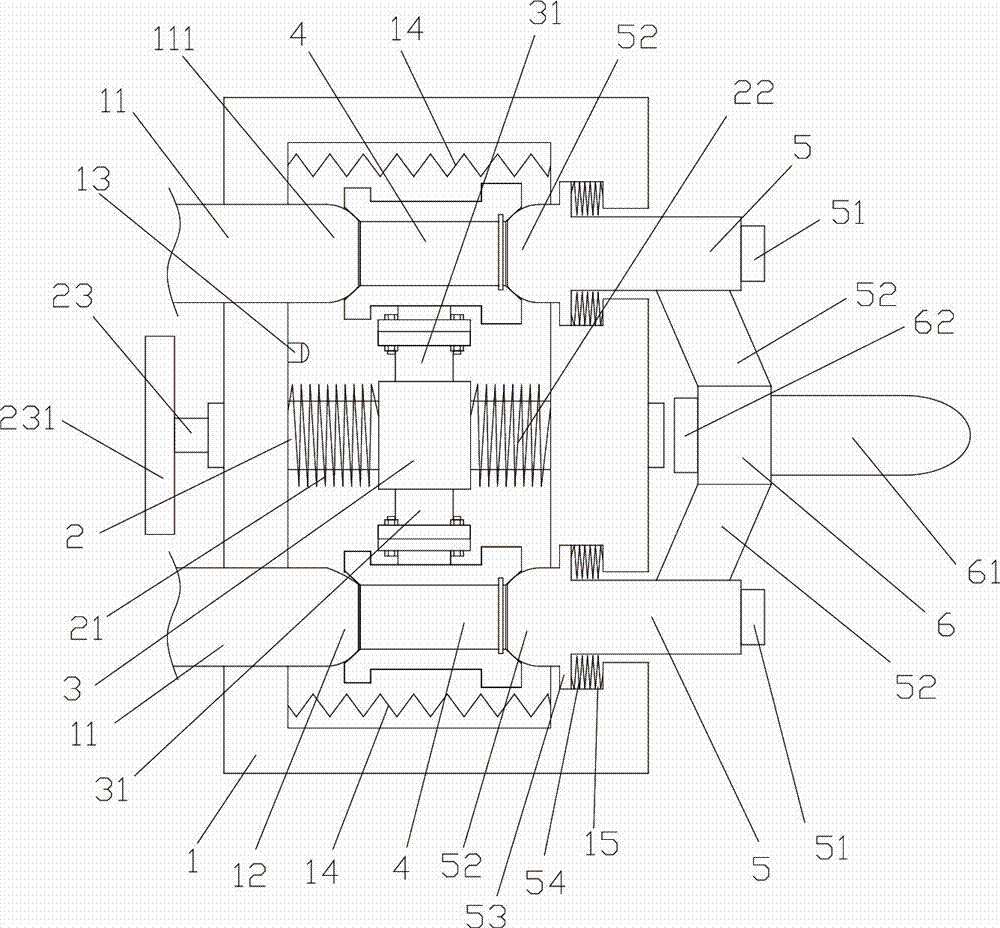

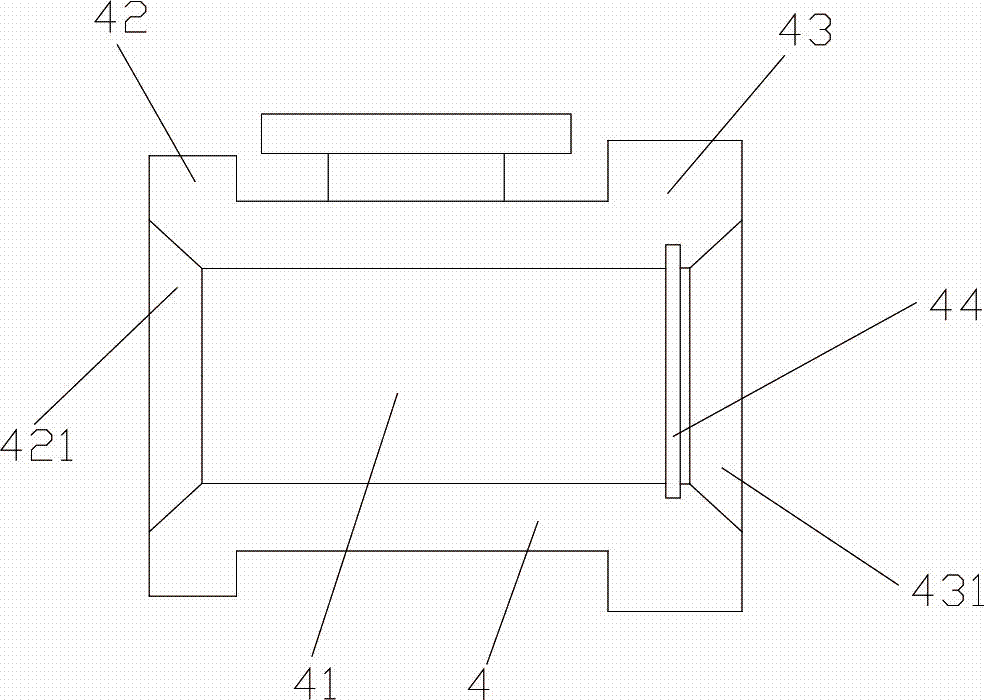

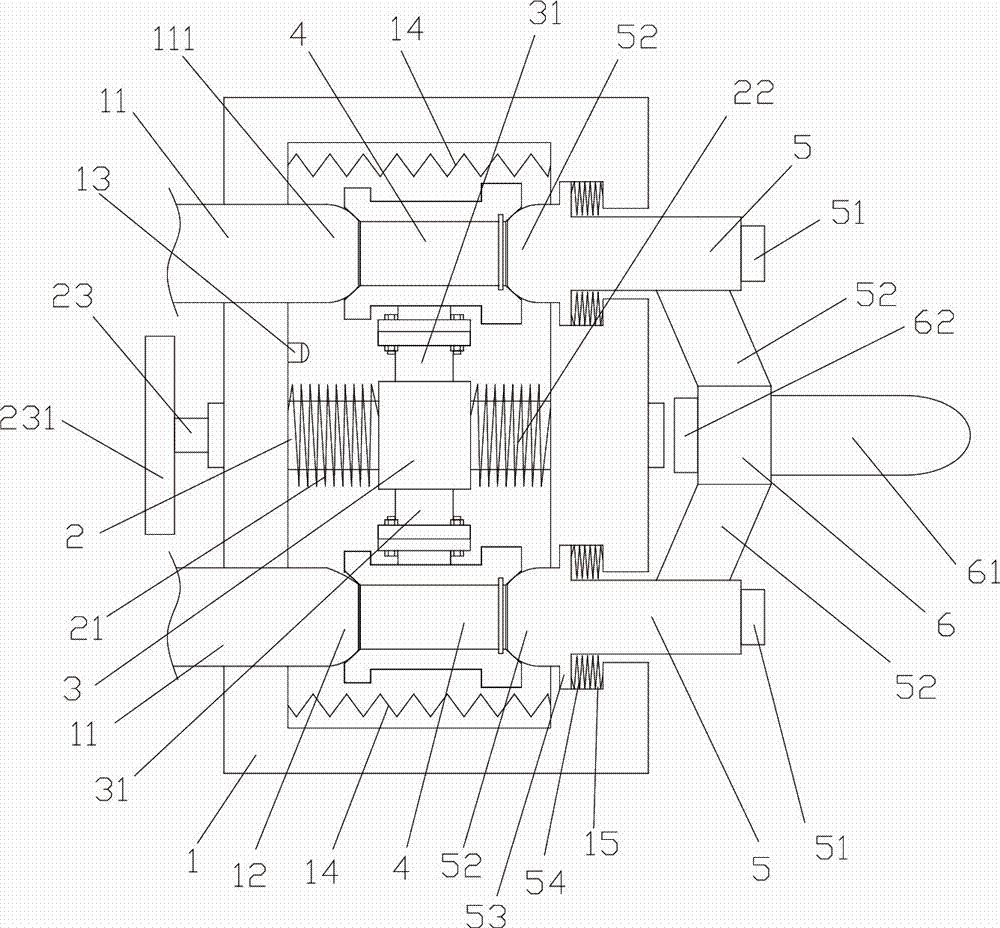

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 2 As shown, an injection molding machine includes a constant temperature box 1, a rotating shaft 2 is arranged in the middle of the constant temperature box 1, and several feed pipes are uniformly distributed around the rotary shaft 2 on the side wall of the constant temperature box 1. 11. The feed pipe 11 is connected to different material boxes, and the end of the feed pipe 11 is provided with a semi-spherical discharge end 111; the other side wall of the thermostat 1 corresponds to the feed pipe 11 An equal number of communication holes are provided, and a discharge pipe 5 is arranged in the communication hole, and the discharge pipe 5 is provided with a semi-spherical feeding end 52; the rotary shaft 2 is provided with a connecting part 3, and the A plurality of connection terminals 31 are evenly arranged on the connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap