Environment-friendly ultra-lightweight inflation-free flexible damping network tire and forming mold and method

An air-free and environmentally friendly technology, which is applied to non-pneumatic tires, tire parts, tire treads/tread patterns, etc., can solve problems such as poor elasticity and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

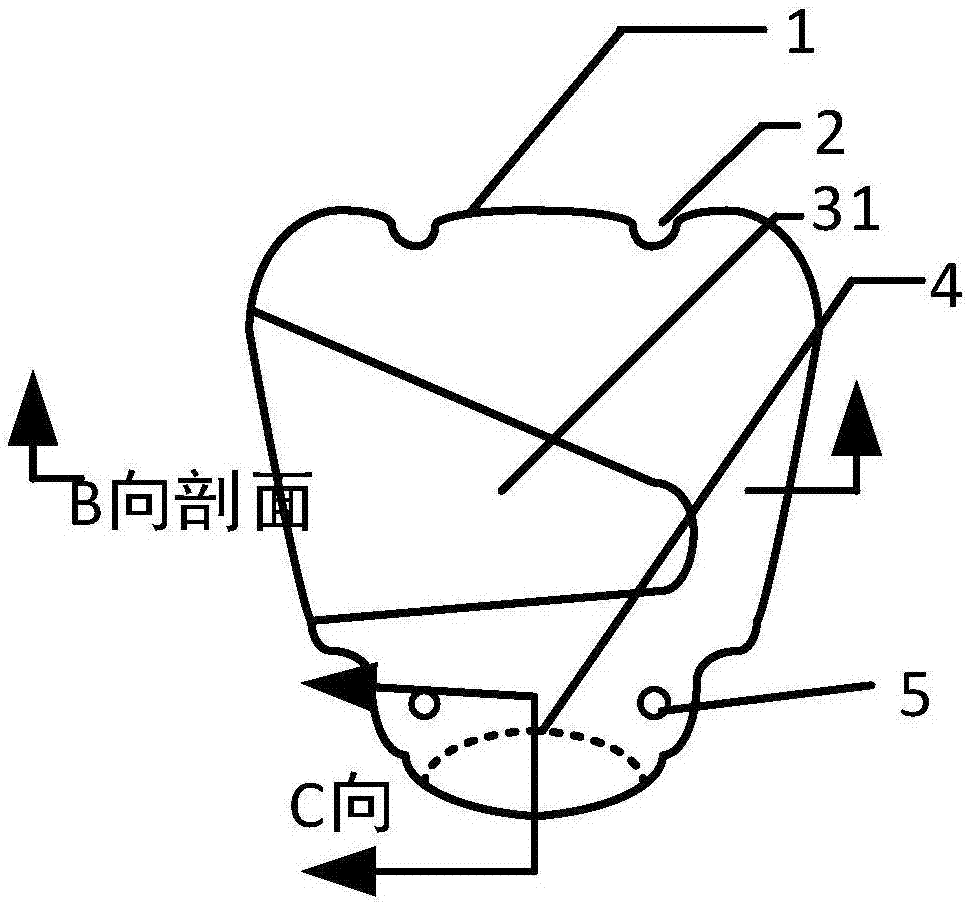

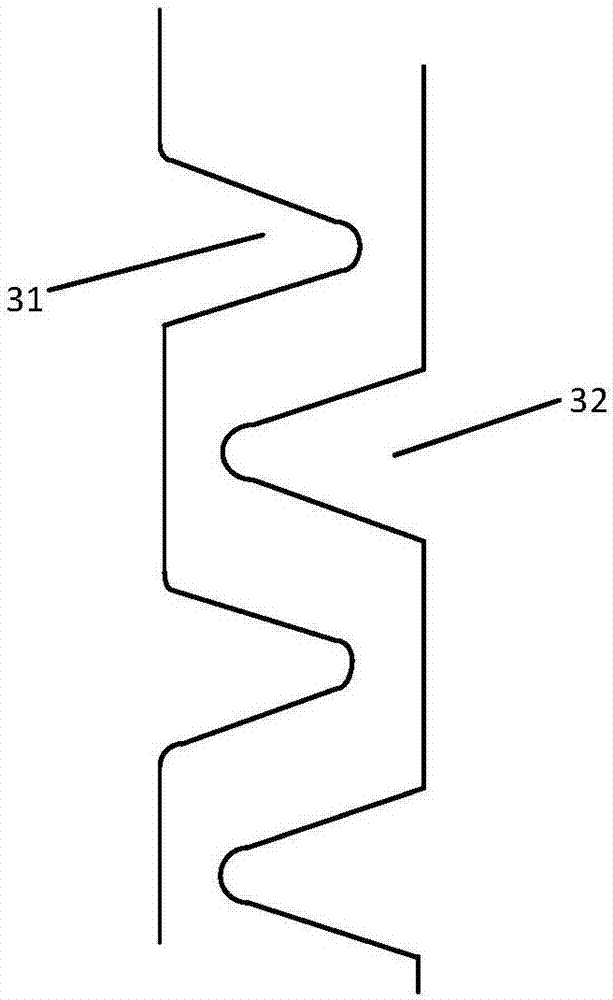

[0046] A specific embodiment, such as figure 2 As shown, the first hole 31 and the second hole 32 are tapered blind holes or tapered through holes, and the tapered through holes are beneficial to heat dissipation and weight reduction.

[0047] A specific embodiment, such as figure 2 As shown, the lower edge of the tapered blind hole is nearly horizontal, the upper edge is inclined from top to bottom, and the depth of the tapered blind hole is about four-fifths of the tire width.

specific Embodiment approach

[0048] A specific embodiment, the first holes 31 and the second holes 32 are arranged in multiple layers along the radial direction of the tire.

[0049] A specific embodiment, the inner surface of the tire is also provided with a number of keyway notches, which are inlaid and matched with the raised keys on the specific power output hub (driving wheel) to form a seamless one, and together with the bead line to hug the hub, Form the integral synchronization of the wheel and the tire.

[0050] The invention uses environmentally friendly materials to produce light weight, reliable load-bearing, good heat dissipation, and long life, which solves the industry problem of hard shock absorption when the air-free tire has good load-bearing, does not produce waste tire pollution, is beneficial to the ecological environment, and uses a simple mold The tires with relatively complex structures are produced, which solve the problems of tire heat dissipation, high energy consumption, poor s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap