Physical method and system for concentrating brine and removing salts

A technology for concentrating brine and brine, applied in the field of physical methods and systems for concentrating brine and removing magnesium, can solve problems such as heat waste, insufficient heat exchange between hot air and water, and large heat loss, and achieve enhanced air convection and energy saving Effect of energy consumption and content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

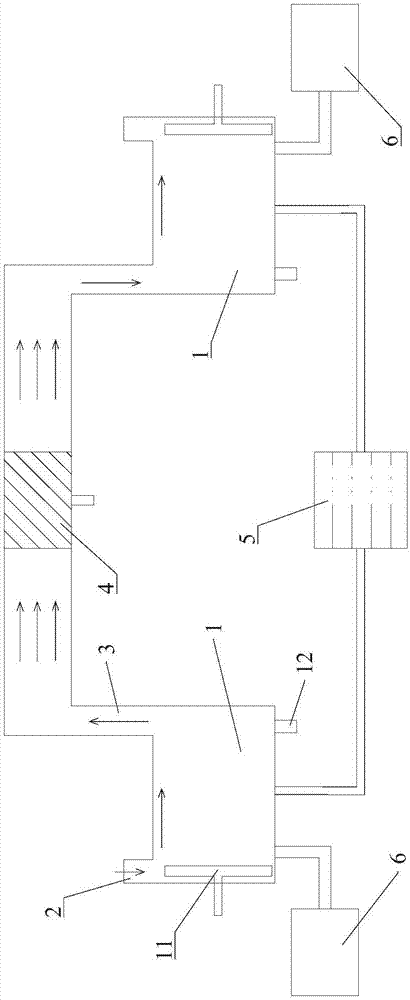

[0049] A method for concentrating brine and desalting, comprising the steps of:

[0050] 1) Raise the temperature of the brine, enhance the air convection on its surface, accelerate the evaporation until the salt is close to saturation or saturated state, and obtain the initially concentrated brine;

[0051] 2) cooling the preliminary concentrated brine to precipitate the salt therein, separate the solid and liquid, and collect the remaining brine;

[0052] 3) Repeat the above two steps for the remaining brine, further concentrate the brine and separate the precipitated salt, and stop the concentration when the production needs are reached.

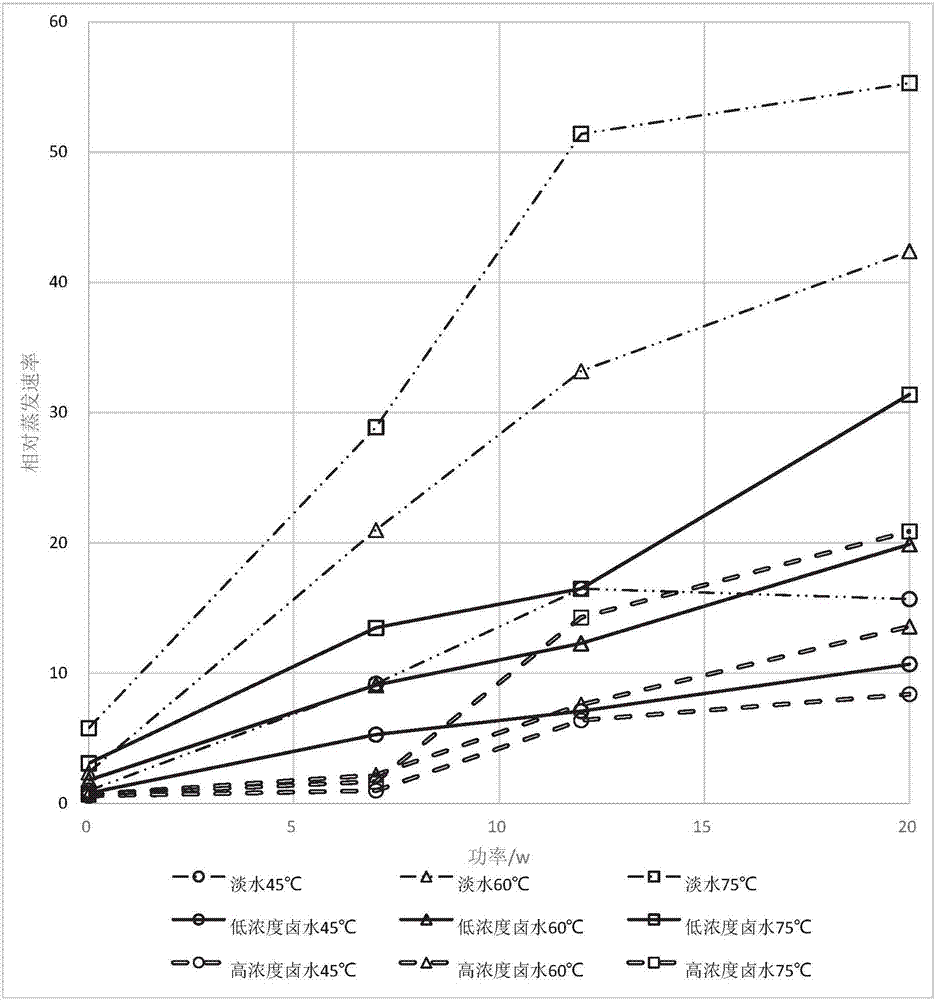

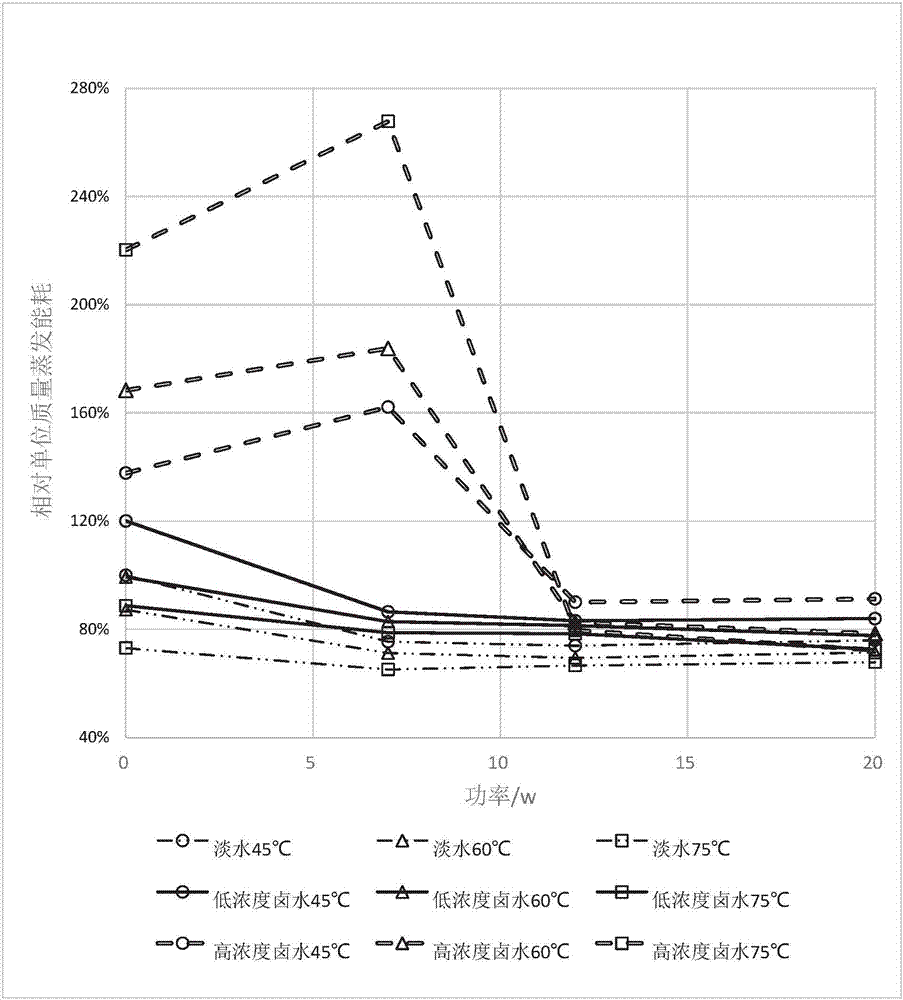

[0053] As the temperature rises, while accelerating the evaporation rate, energy consumption can be further reduced. As a further improvement of the above method, the temperature of the brine is raised to above 30°C, preferably above 40°C, 45°C, and above 50°C; ~75°C.

[0054] As a further improvement of the above method, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com