A blue-green silicate ultra-long afterglow luminescent material and its preparation method

A technology of long afterglow luminescence and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effect of low cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

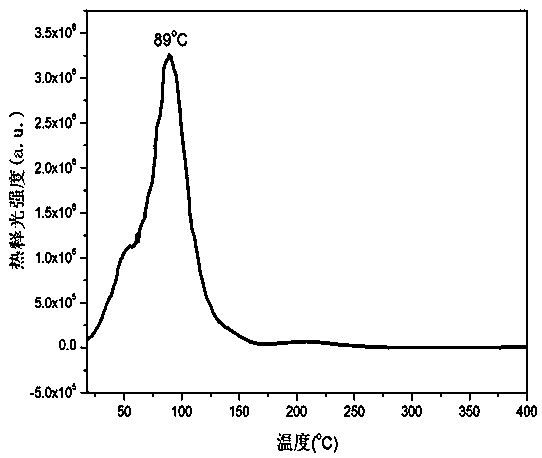

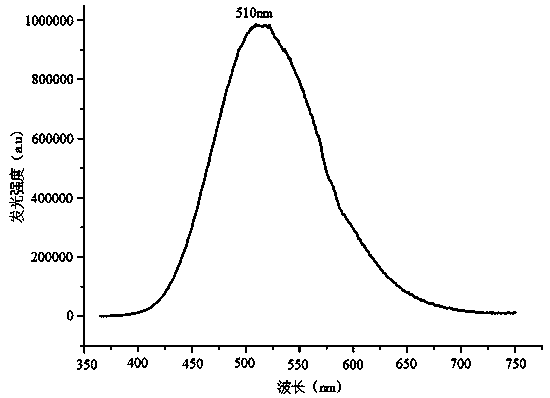

[0039] Press Ba 0.9975 Si 2 o 5 :Eu 0.0025 , Pr 0.01 The stoichiometric ratio shown in the molecular formula, respectively weigh 0.3946gBaCO 3 , 0.2403g SiO 2 , 0.00088g Eu 2 o 3 and 0.0016g Pr 2 o 3 , grind the weighed raw materials to micron-sized powder, mix them uniformly and put them into an alumina crucible, and then place them in an environment with a temperature of 1100°C and a reducing atmosphere for 6 hours. The reducing atmosphere consists of 95% by volume N 2 and 5% H 2 The composition is naturally cooled to room temperature after calcination, and after grinding, a blue-green silicate ultra-long afterglow luminescent material is obtained. The pyrolysis spectrum of the blue-green silicate ultra-long afterglow luminescent material, such as figure 1 As shown in the figure, the thermal release peak of the luminescent material is at 89°C, which indicates that in the matrix used, through the doping of activator ions and co-activator ions, a more suitable dept...

Embodiment 2

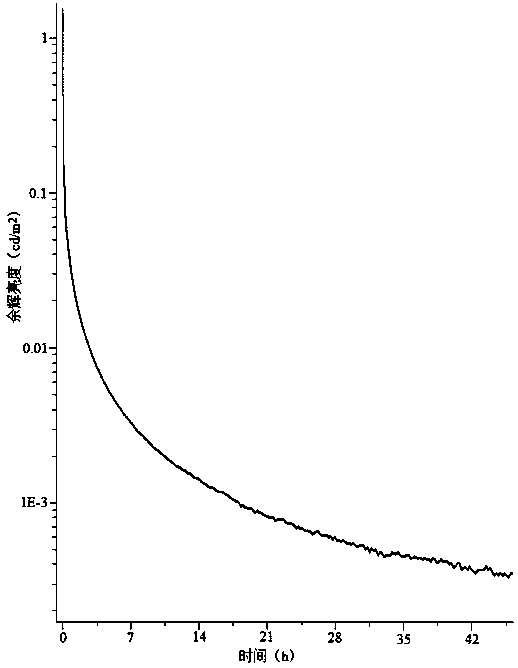

[0041] Press Ba 0.9975 Si 2 o 5 :Eu 0.0025 , Nd 0.01 The stoichiometric ratio shown in the molecular formula, respectively weigh 0.3946gBaCO 3 , 0.2403g SiO 2 , 0.00088g Eu 2 o 3 and 0.0016g Nd 2 o 3 , Grind the weighed raw materials to the micron level, mix them evenly and put them into an alumina crucible, then place them at a temperature of 1300 ° C, and pass them into a reducing atmosphere for 4 hours. The reducing atmosphere consists of 95% by volume N 2 and 5% H 2 composition. After the calcination is completed, it is naturally cooled to room temperature, and after grinding, a blue-green silicate ultra-long afterglow luminescent material is obtained. The afterglow spectrum of the long afterglow luminescent material after being irradiated under the ultraviolet light source for 10 minutes is as follows: Figure 4 As shown, it can be seen from the figure that the long-lasting luminescent material can continuously emit a luminous brightness of 0.32mcd / m2 that ca...

Embodiment 3

[0043] Press Ba 0.9975 Si 2 o 5 :Eu 0.0025 , Ho 0.01 The stoichiometric ratio shown in the molecular formula, respectively weigh 0.3946gBaCO 3 , 0.2403g SiO 2 , 0.00088g Eu 2 o 3 and 0.0017g Ho 2 o 3 , grind the weighed raw materials to the micron level, mix them uniformly and put them into an alumina crucible, then place them at a temperature of 1200°C and pass them into a reducing atmosphere for calcination for 5 hours. The reducing atmosphere consists of 95% by volume N 2 and 5% H 2 composition. After the calcination is completed, it is naturally cooled to room temperature, and after grinding, a blue-green silicate ultra-long afterglow luminescent material is obtained. The afterglow spectrum of the long afterglow luminescent material after being irradiated under the ultraviolet light source for 10 minutes is as follows: Figure 5 As shown, it can be seen from the figure that the luminescent material can continuously emit more than 20 hours of luminous brightnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com