Fiber reinforcement material based on liquid metal and preparation method thereof

A fiber skeleton and liquid metal technology, applied in the field of fiber skeleton materials, can solve the problems of poor mechanical properties of pure liquid metal, and achieve the effect of good electrical conductivity and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

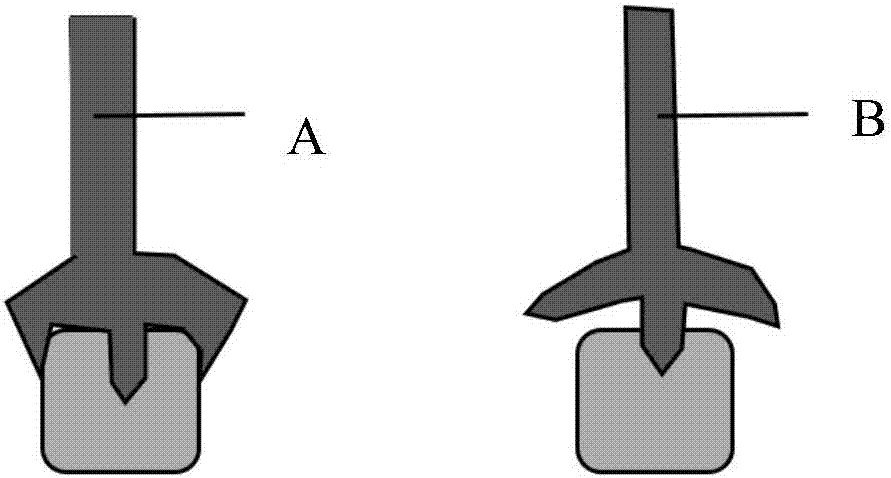

Method used

Image

Examples

Embodiment 1

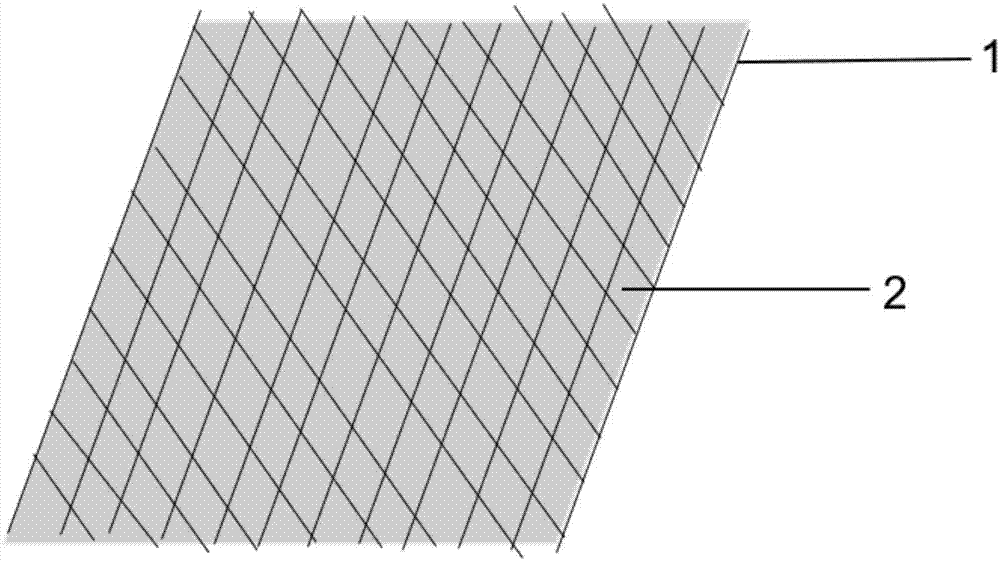

[0028] The fiber skeleton material based on liquid metal uses carbon fiber as the fiber skeleton, and gallium indium 24.5 alloy as the filling material. The diameter of the carbon fiber is 0.5mm, and it is woven into a plane hexagonal structure by electrospinning technology, and the unilateral length of the hexagonal hole is 1mm. The volume ratio of carbon fiber to liquid metal is about 1:20.

Embodiment 2

[0030] The fiber skeleton material based on liquid metal uses copper wire as the fiber skeleton, and gallium indium 24.5 alloy as the filling material. The diameter of the copper fiber is 0.1mm, and it is woven into a three-dimensional tetrahedron structure by metal additive manufacturing technology, and the side length of the tetrahedron with voids is 0.5mm. The volume ratio of copper wire fiber to liquid metal is about 1:15.

Embodiment 3

[0032] The fiber skeleton material based on liquid metal adopts nylon fiber and iron wire material as the composite fiber skeleton, the nylon fiber is in the radial direction, the iron wire is in the weft direction, and gallium indium tin alloy is used as the filling material. Among them, the diameter of nylon fiber is 0.5mm, and the diameter of iron wire is 0.2mm. It is woven into a quadrilateral structure by electrospinning technology, and the side length of the hole is 1mm. The volume ratio of fiber skeleton to liquid metal is about 1:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com