Boosted engine system of a motor vehicle

A technology of engine and supercharged air, applied in the direction of machines/engines, engine components, combustion engines, etc., can solve problems such as increased fuel consumption, large loss of power generation circuits, and inability to handle electrical needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

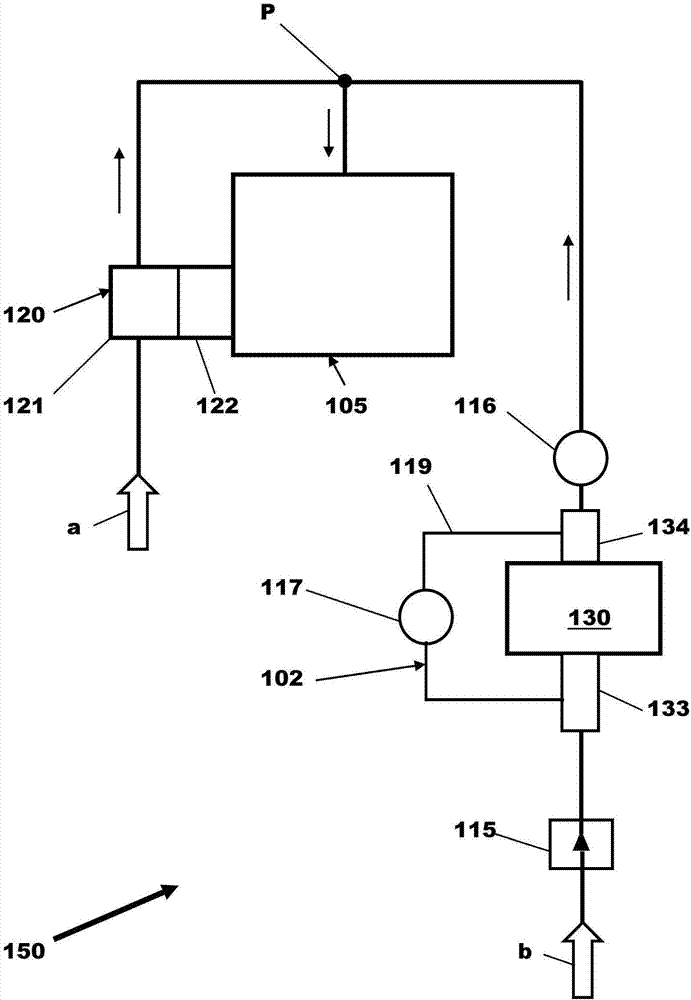

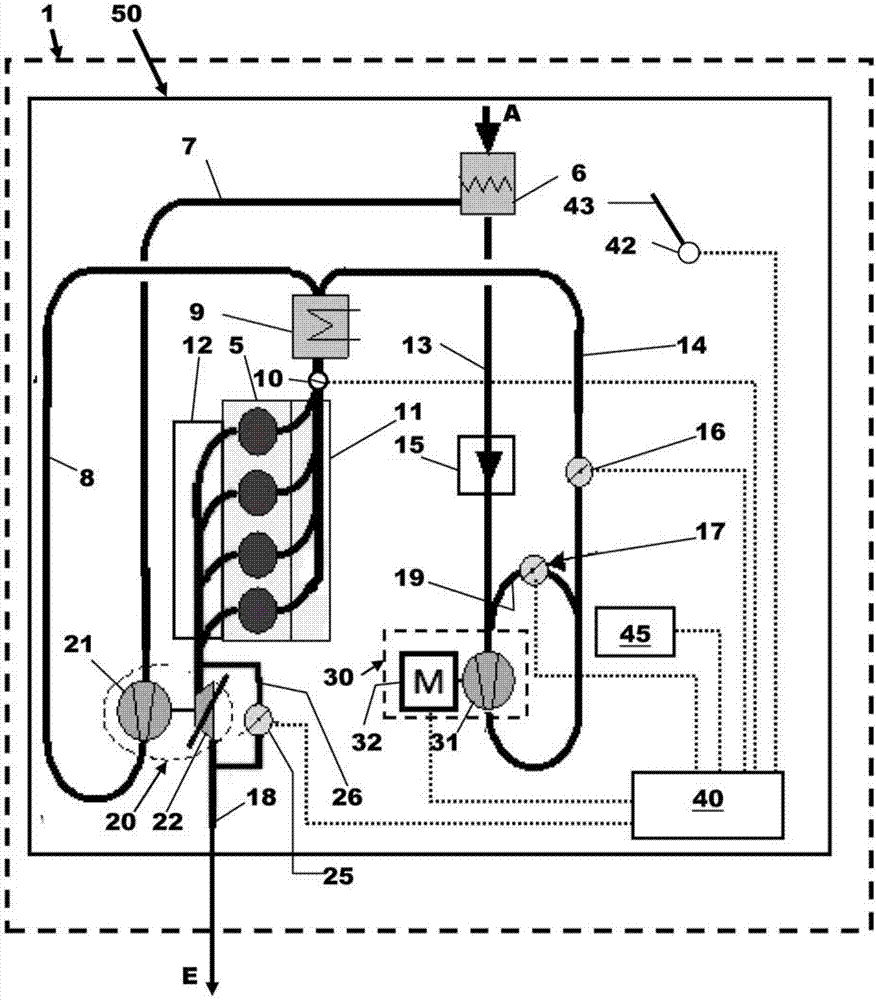

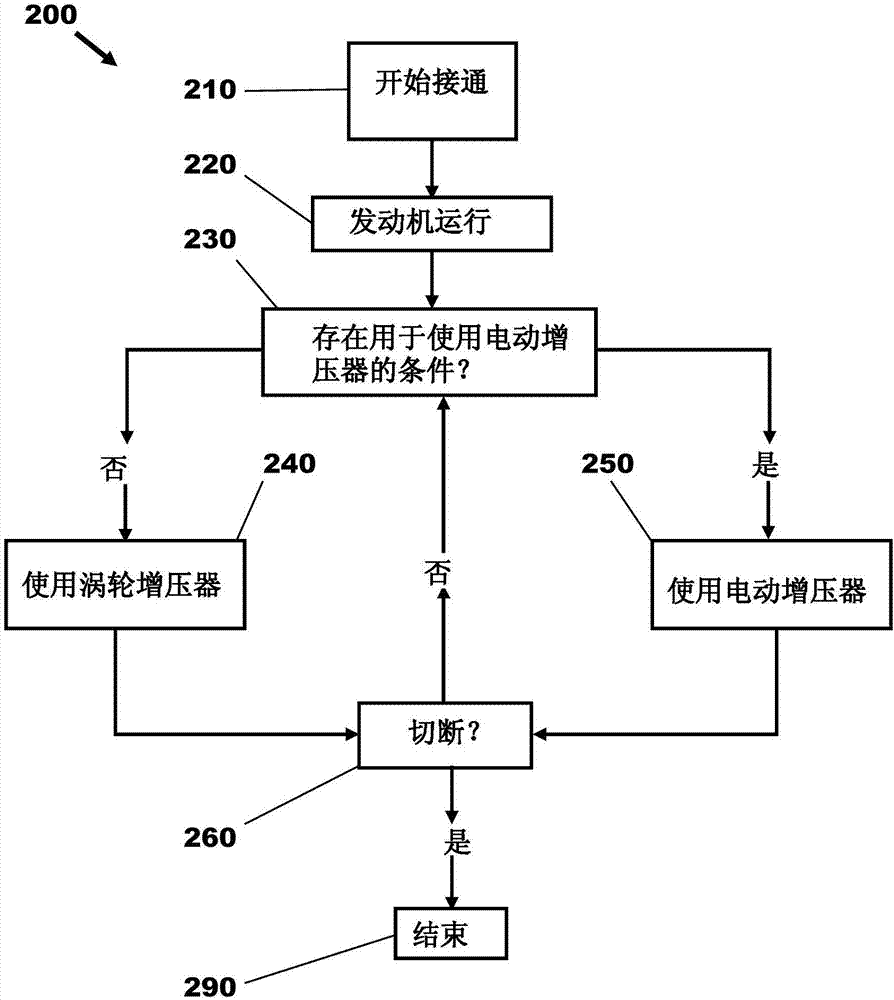

[0017] The following description is concerned with operating an electric compressor arranged in parallel with a turbocharger compressor (such as figure 1 and figure 2 A system and method for providing a desired boost pressure to an engine to deliver an operator demanded torque. another example figure 1 and figure 2 As shown in , the electric compressor may include a recirculation circuit and one or more valves for selectively fluidly coupling the electric compressor with an intake manifold of the engine. In addition to the boost that can be supplied by the turbocharger compressor, when increased boost is required to deliver the current operator demanded torque, the electric compressor can be operated to provide increased boost pressure, such as Figure 3a method is shown. However, the boost pressure output by the electrically operated compressor may first build up within the recirculation loop to a level equal to or greater than the boost pressure provided to the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com