Barrel mounting type large-caliber thick-wall connecting pipe of boiler and pressure vessel and connecting method

A pressure vessel and large-diameter technology, which is applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of long cycle time, small processing volume, and low efficiency, so as to improve production efficiency and manufacture The effect of process simplification and economic benefit optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

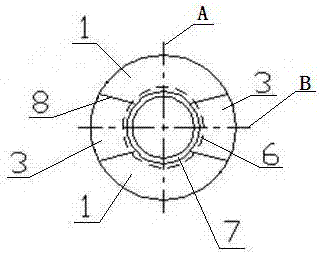

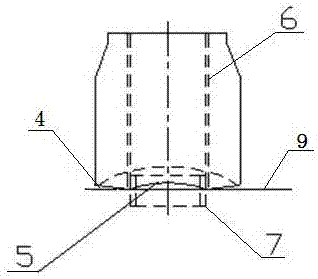

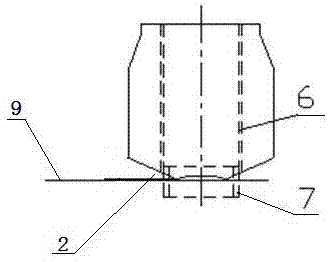

[0028] A large-diameter thick-walled connecting pipe for boilers and pressure vessels, which consists of a connecting pipe body, the shape of the welding groove on the bottom surface of the connecting pipe includes four intersecting planes, forming a Class D weld groove with the outer surface of the cylinder, The inclination angle of the plane welding groove is between -35° and 40°.

Embodiment 2

[0030] According to the large-diameter thick-walled connecting pipe of the boiler and pressure vessel described in Embodiment 1, the four intersecting planes are composed of two pairs of symmetrically arranged plane welding grooves, one pair of which is located in the axial direction of the cylinder. The inclination angle of the plane welding groove is 15°~40°, and the inclination angle of the plane welding groove at a position 90 degrees to it is -35°~35°.

Embodiment 3

[0032] According to the large-diameter thick-walled nozzle placed on the cylinder of the boiler and pressure vessel described in Embodiment 1, the four intersecting planes include two pairs of symmetrically arranged plane welding grooves, and one pair of plane welding grooves located in the axial direction of the cylinder The groove is a pair of combined plane welding grooves, the combined plane welding groove is a folded groove composed of two planes, and the inclination angle of the plane welded groove on the inner plane of the folded groove is between 25° and 40° , the inclination angle of the plane welding groove on the outer plane of the folding surface groove is 5°~20°, and the inclination angle of the other pair of plane welding grooves at 90° to the axial direction of the cylinder is -35°~35°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com