A kind of furan resin production system and process

A furan resin and production system technology, which is applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical/physical chemical fixed reactors, etc., can solve problems such as rough proportioning and low mixing production efficiency , to achieve the effect of expanding the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

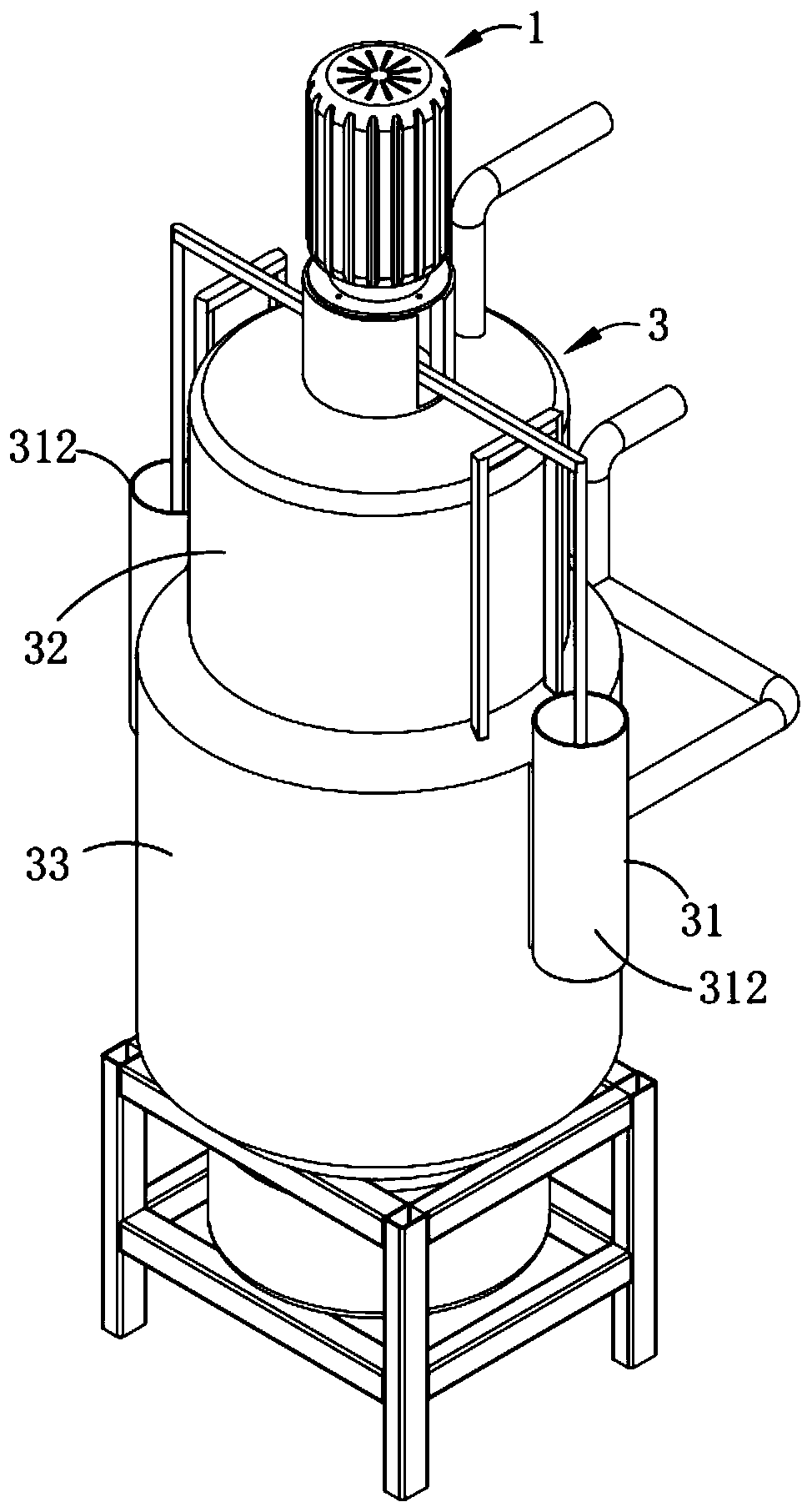

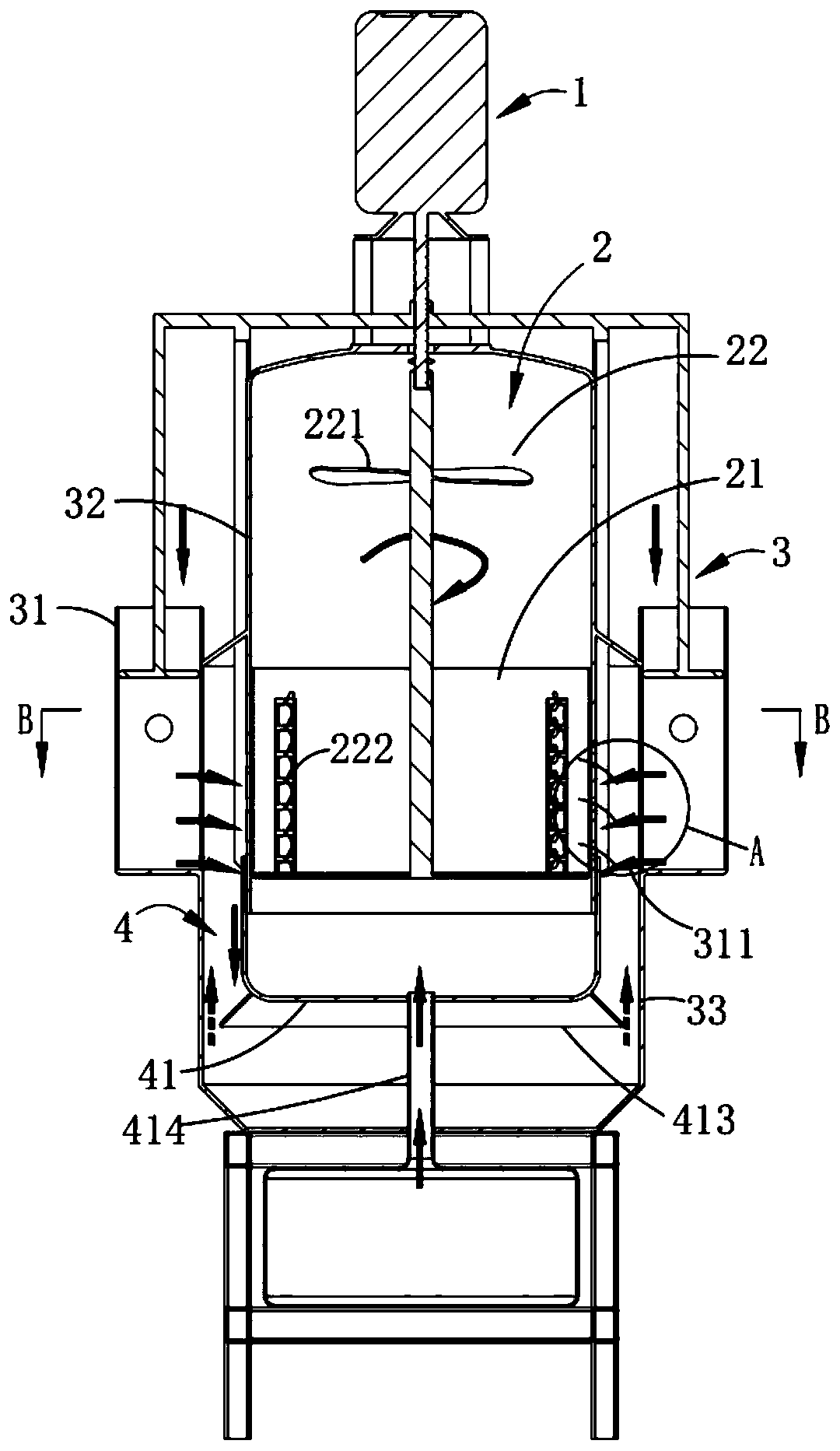

[0045] Such as figure 1 , 2 , Shown in 3 and 4, a kind of furan resin production system, comprises power unit 1, also comprises:

[0046] Stirring mechanism 2, said stirring mechanism 2 includes a stirring bin 21, a stirring assembly 22 arranged in the stirring bin 21, and a plurality of feeding openings 23 opened on said stirring bin 21, which is formed by mixing various components After the main material enters the mixing chamber 21, it is broken up and stirred by the stirring assembly 22 and then output through the discharge...

Embodiment 2

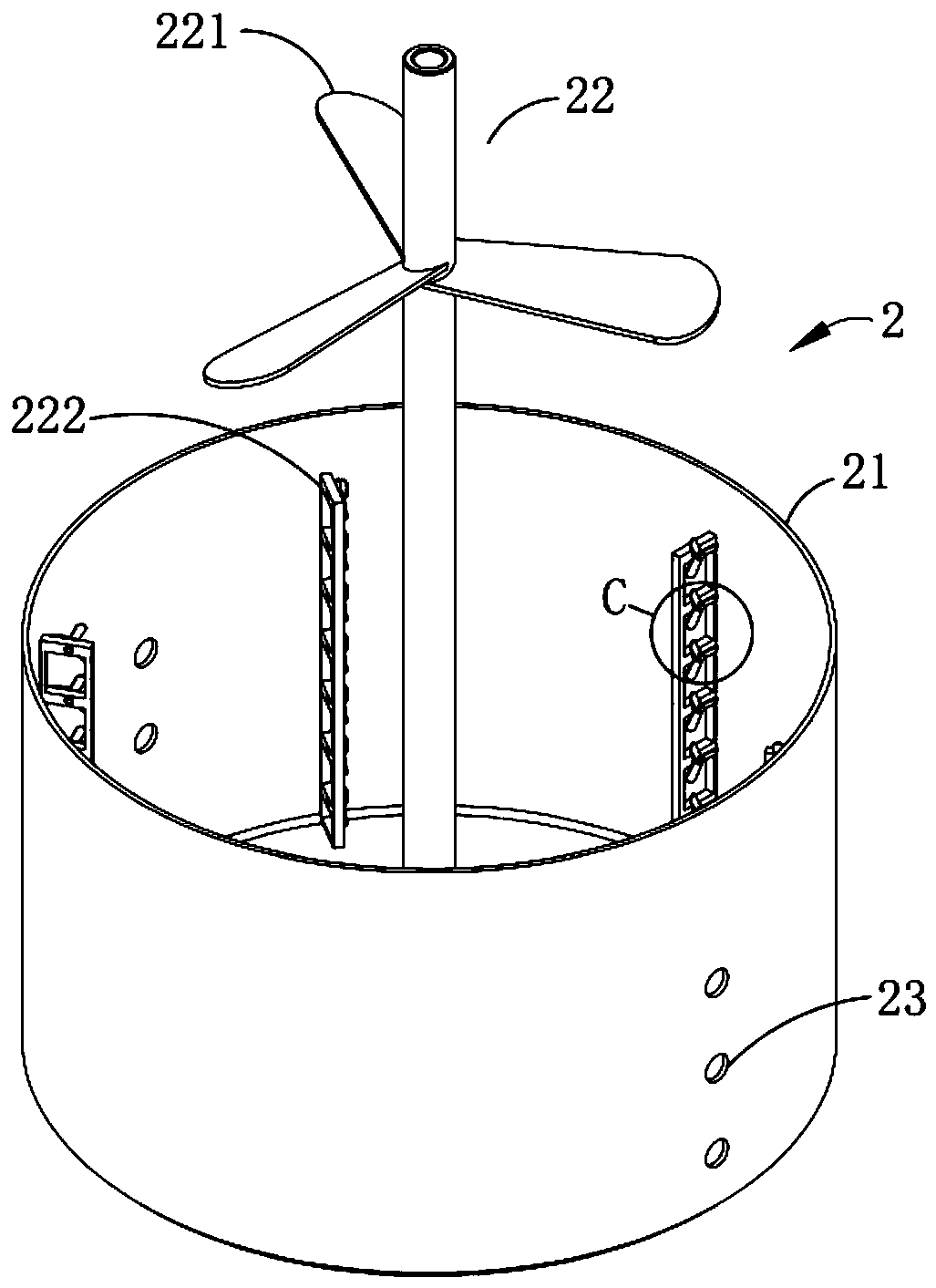

[0057] Such as figure 2 , 3 and 9, wherein the parts identical or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment, and for the sake of simplicity, only the differences from the first embodiment are described below; the second embodiment is different from the first embodiment The difference is that: the stirring assembly 22 includes a breaking part 221, a plurality of stirring parts 222 uniformly arranged on the inner wall of the mixing chamber 21, and a stirring output area 223, and the upper and lower ends of the breaking part 221 They are respectively fixedly connected with the power mechanism 1 and the stirring bin 21, and the stirring part 222 is fixedly arranged on the stirring bin 21; in this embodiment, the stirring parts 222 are uniformly arranged on the stirring bin 21 On the inner peripheral surface, the number thereof is preferably six.

[0058] Among them, such as figure 2 , 3 As shown in and 9...

Embodiment 3

[0062] Reference attached Figure 12 A furan resin production system process in Example 3 of the present invention is described.

[0063] A kind of furan resin production technology, comprises the following steps:

[0064] (a) The main material mixing process, the main material formed by mixing various materials enters the mixing chamber 21, is broken up by the dispersing part 221 in a rotating manner, and then falls into the mixing chamber 21, and then passes through the stirring output area 223 After the multiple stirring parts 222 are stirred in a rotating manner, they are output into the mixing chamber 33 through the discharge port 23;

[0065] (b) Preliminary mixing process, the main material stirring assembly 22 rotates and stirs while driving the compression part 313 to move, and quantitatively outputs the auxiliary material into the mixing chamber 33 in a compressed manner to contact and mix with the main material, and synchronously drives the catalyst output chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com