Spraying equipment adopting hydraulic carbon dioxide as solvent

A technology of carbon dioxide and spraying equipment, which is applied in the direction of liquid spraying devices, spraying devices, etc., and can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

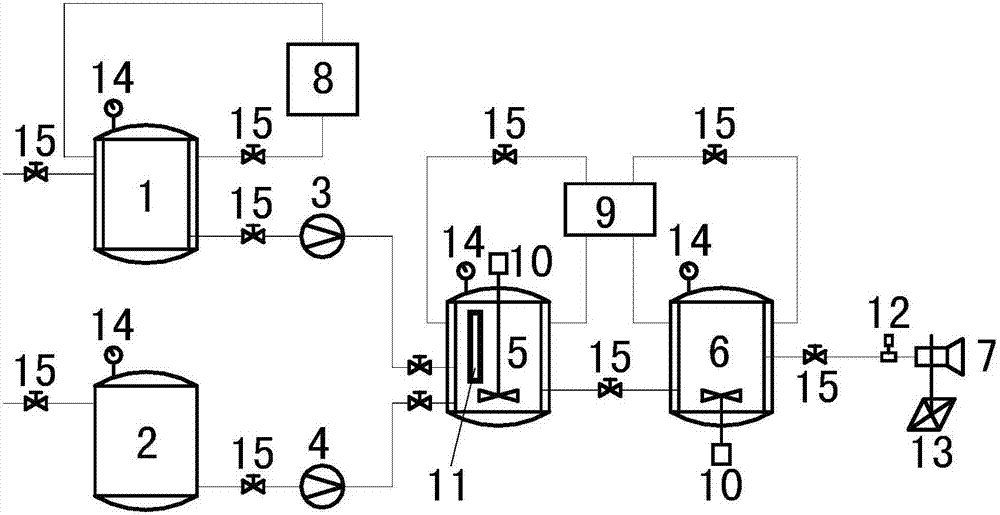

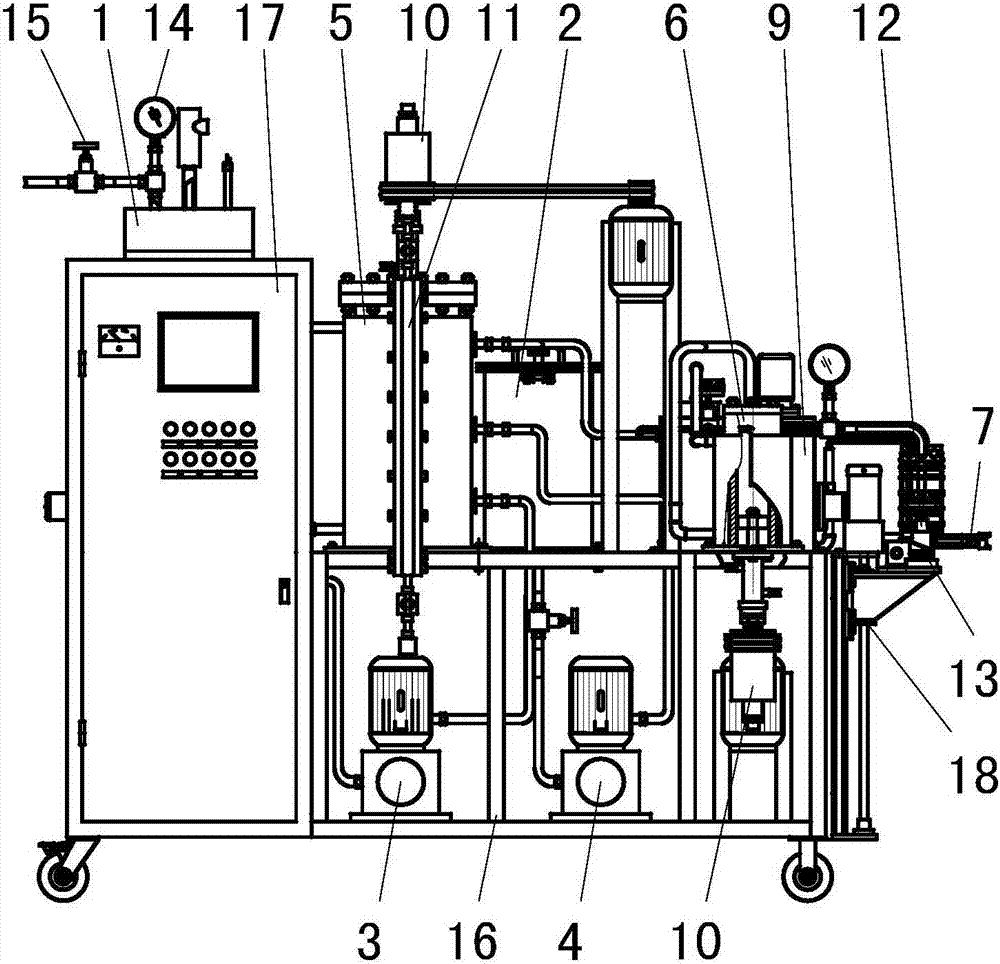

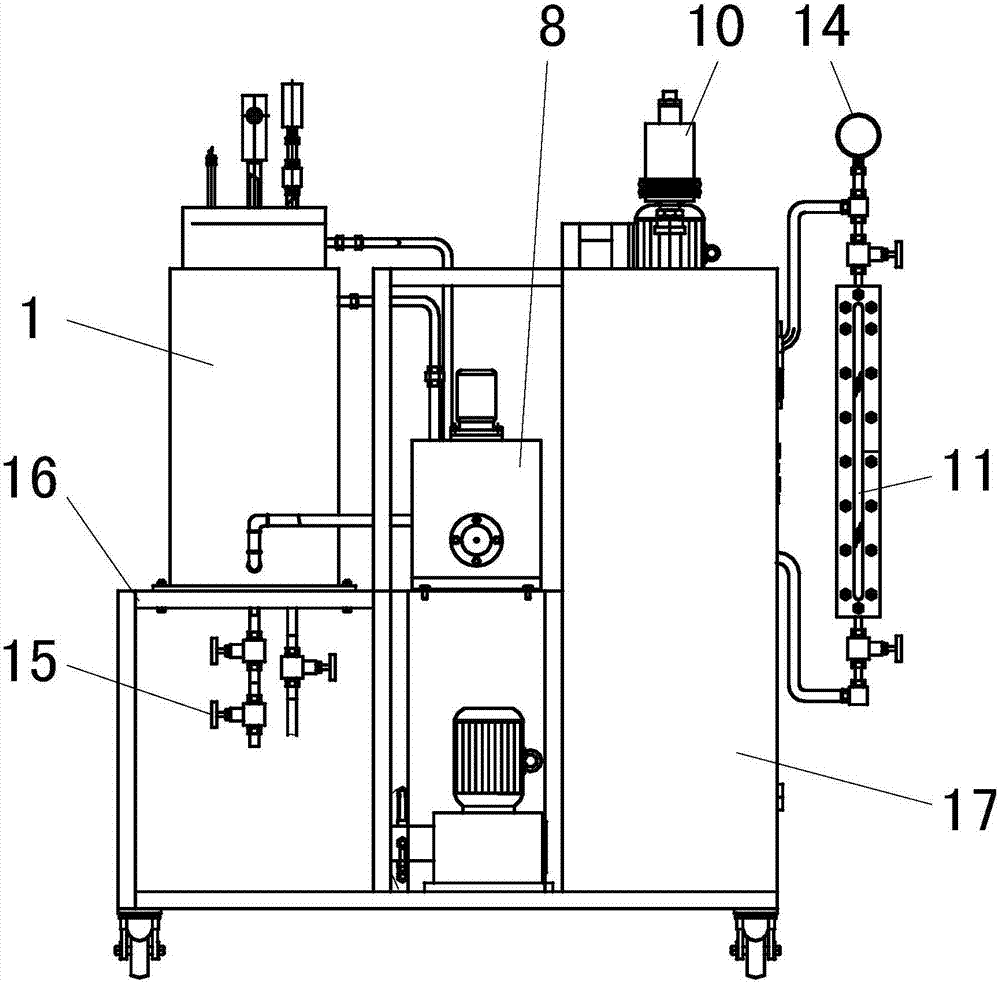

[0042] This example Figure 1~3 Shown, during concrete implementation, at first control cabinet 17 is fixed on the frame dolly 16, then refrigeration device 8 is installed in the middle of frame dolly 16, and heating device 9 is installed in the other end in the middle of frame dolly 16 again. Then the CO 2 Storage tank, mixing tank 5, paint storage tank 2, buffer tank 6, CO 2 The pressure injection pump 3 and the paint injection pump 4 are installed on the frame trolley 16 around the refrigeration device 8 and the heating device 9 , and finally the pipelines and electrical appliances between each equipment are connected with the control cabinet 17 . The drag chain hose transmission device 18 should be installed near the nozzle assembly 7, and the hose, drag chain and electric heating belt should be installed together. After the installation is complete, the program can be debugged after checking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com