All-position automatic outside welding system for pipes

An all-position, automatic technology, applied in the direction of welding equipment, auxiliary equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

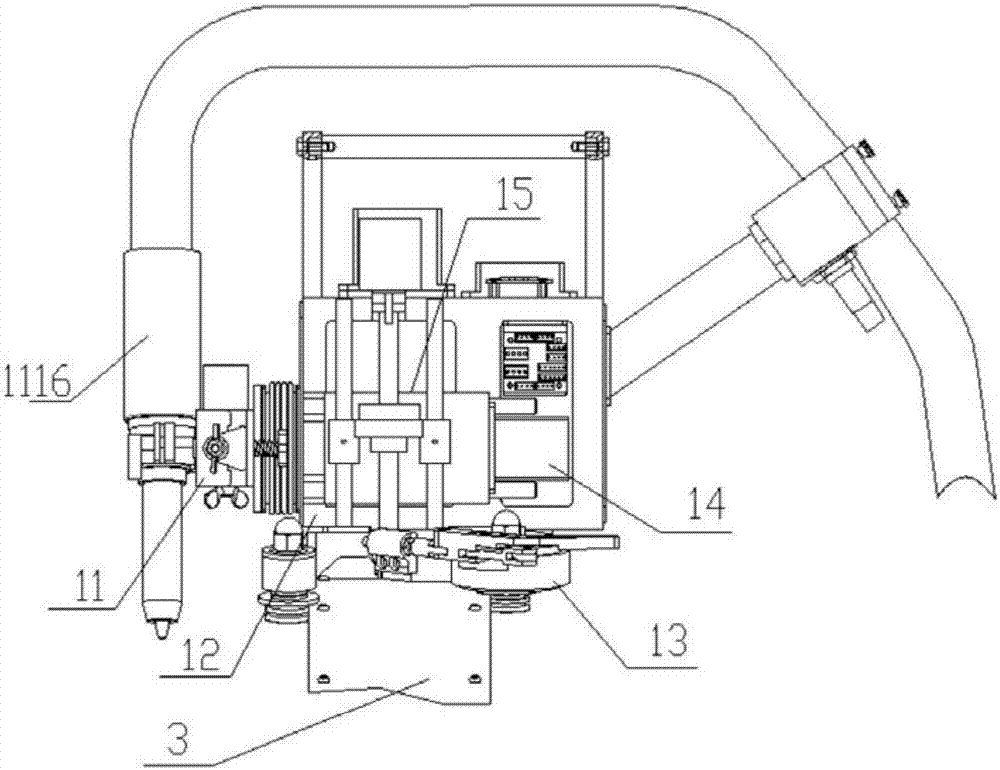

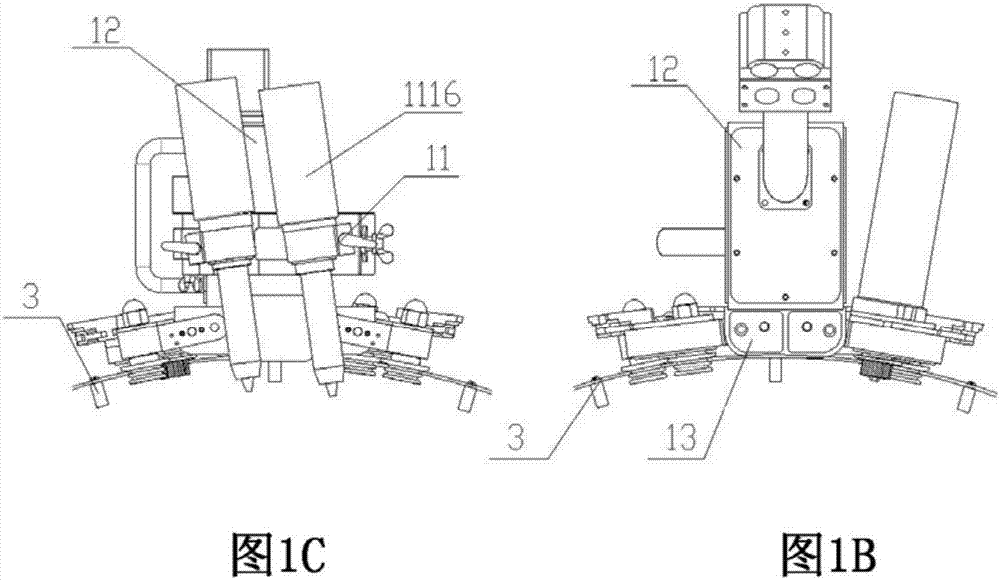

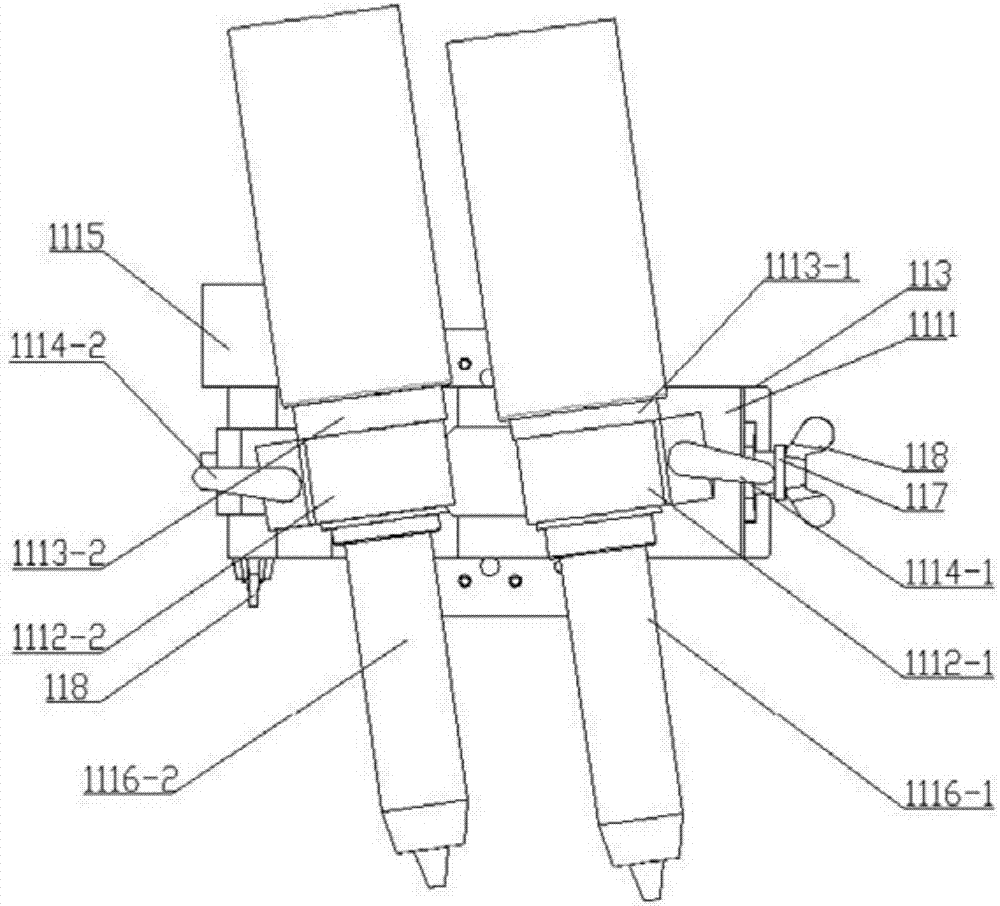

[0310] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following is a specific description of the gas shielded welding type all-position automatic external welding system for pipelines proposed according to the present invention in conjunction with the accompanying drawings and preferred embodiments. Embodiments, structures, features and effects thereof are described in detail below.

[0311] The main structure of the present invention is made up of welding trolley 1, external welding control system 2, track 3, shielding gas system 6, and the first pipe joint 4 and the second pipe joint 5 that are paired are carried out semi-radial welding, consists of two Such a system completes the welding of the entire joint, and completes all the welding processes of root welding, heat welding, filling, and covering.

[0312] The external welding control system 2 of the present invention mainly uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com