Functional buffer layer of sole

A buffer layer and functional technology, applied in the field of shoe components, can solve the problems of heavy weight, poor anti-slip and shock absorption effect, etc., and achieve the effect of simple shape and improved shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

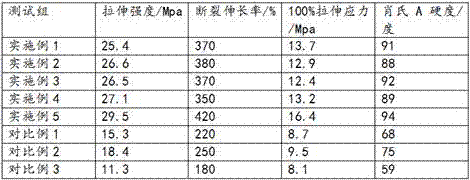

Examples

Embodiment 1

[0016] A buffer layer for functional shoe soles, characterized in that it comprises the following components in parts by weight: polyisoprene 85, cyclohexylthiophthalimide 9, tetraalkylthiuram disulfide 6. 3,5-diethyltoluene-2,6-diamine 8, polyacrylamide 16, polystyrene nanospheres 23, sea silk fiber 31, ethyl silicate 8, carbon black 11.

Embodiment 2

[0018] A buffer layer for functional shoe soles, characterized in that it comprises the following components in parts by weight: polyisoprene 105, cyclohexylthiophthalimide 15, tetraalkylthiuram disulfide 11. 3,5-diethyltoluene-2,6-diamine 17, polyacrylamide 25, polystyrene nanospheres 29, sea silk fiber 45, ethyl silicate 15, carbon black 23.

Embodiment 3

[0020] A buffer layer for functional shoe soles, comprising the following components in parts by weight: polyisoprene 100, cyclohexylthiophthalimide 14, tetraalkylthiuram disulfide 10, 3, 5-diethyltoluene-2,6-diamine 15, polyacrylamide 22, polystyrene nanospheres 28, sea silk fiber 43, ethyl silicate 13, carbon black 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com