Overburden bed separation sectional isolation grouting-and-bashing coal seam mining complete stoping method

A technology of isolated grouting and overburden layer separation, which is applied in the direction of filling, ground mining, mining equipment, etc., to achieve the effect of ensuring stability, good stability, and a safe and healthy working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

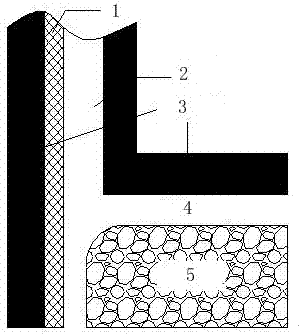

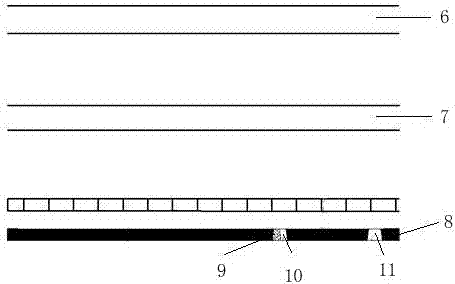

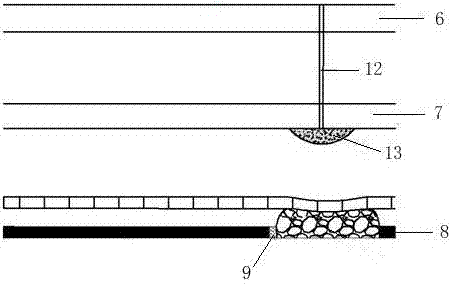

[0047] The purpose of the present invention is to propose a technique for recovering all coal seams by isolation, grouting, subsidence and subsidence of overlying rock and separation layers, canceling coal pillars between sections, realizing mining without coal pillars, ensuring full recovery of coal seams, and greatly improving the recovery rate ; Make it easier for the grouting material to fill the space in the abscission area, and the overlying rock mass is more compact, solid and complete, ensuring the effect of subsidence reduction, and reducing the mine pressure in the middle isolated island section.

[0048] In order to realize the above-mentioned purpose of the invention, the present invention adopts the following technical solutions:

[0049] A method for recovering all coal seams by separating grouting and reducing subsidence by partitioning overlying rock separation layers, said method comprising the following steps:

[0050] The first step: according to the geologi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com