Fully-closed type sintered hot ore cooling and waste heat recovery device

A waste heat recovery device, a fully enclosed technology, applied in furnace cooling, waste heat treatment, lighting and heating equipment, etc., can solve the problems of long heat loss of flue and air ducts, large floor space, and scattered system equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

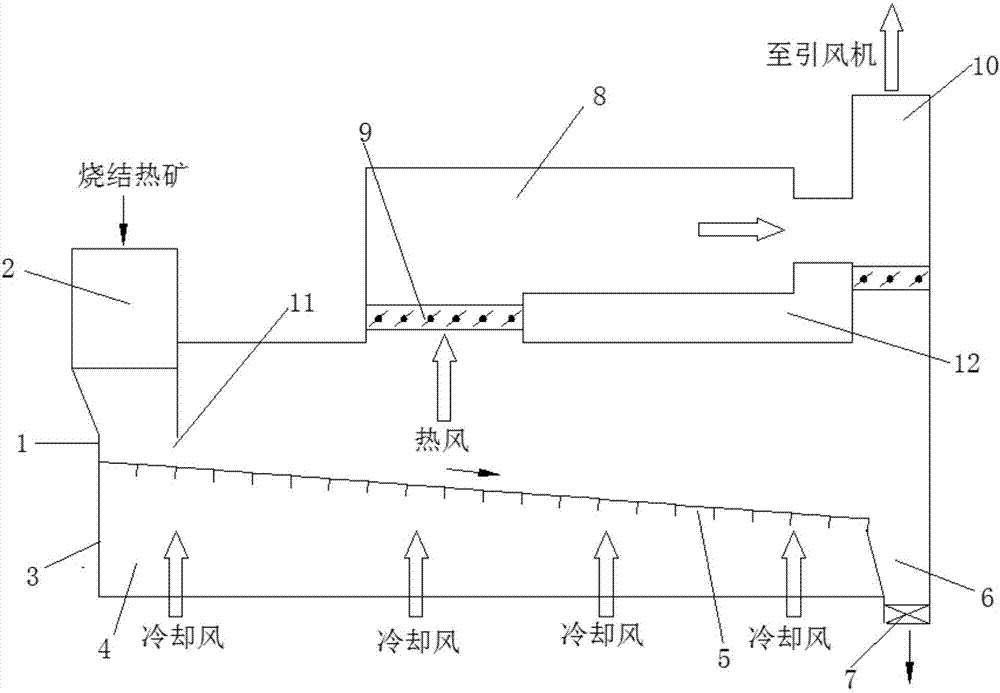

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] see figure 1 As shown, a fully enclosed sintering hot ore cooling and waste heat recovery device includes a shell 1, and a vertically arranged pre-storage section 2 is formed on the upper side of the shell for receiving continuously or intermittently loaded sintering heat ore; the lower part of the housing forms a horizontal cooling section 3, the upper side of the cooling section 3 communicates with the bottom of the pre-storage section, and the inside of the cooling section 3 is provided with an ore material conveyor 5, which passes through the bottom of the cooling section After the introduced cooling air passes through the air cavity 4 at the lower part of the cooling sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com