Test method for water lock damage evaluation of tight sandstone

A technology of water lock damage and tight sandstone, which is applied in the field of oil exploitation, can solve the problems of not considering the initial water content conditions of the formation, achieve accurate formation water lock damage, solve the effect of poor reproducibility of experimental results, and comprehensively evaluate the damage degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

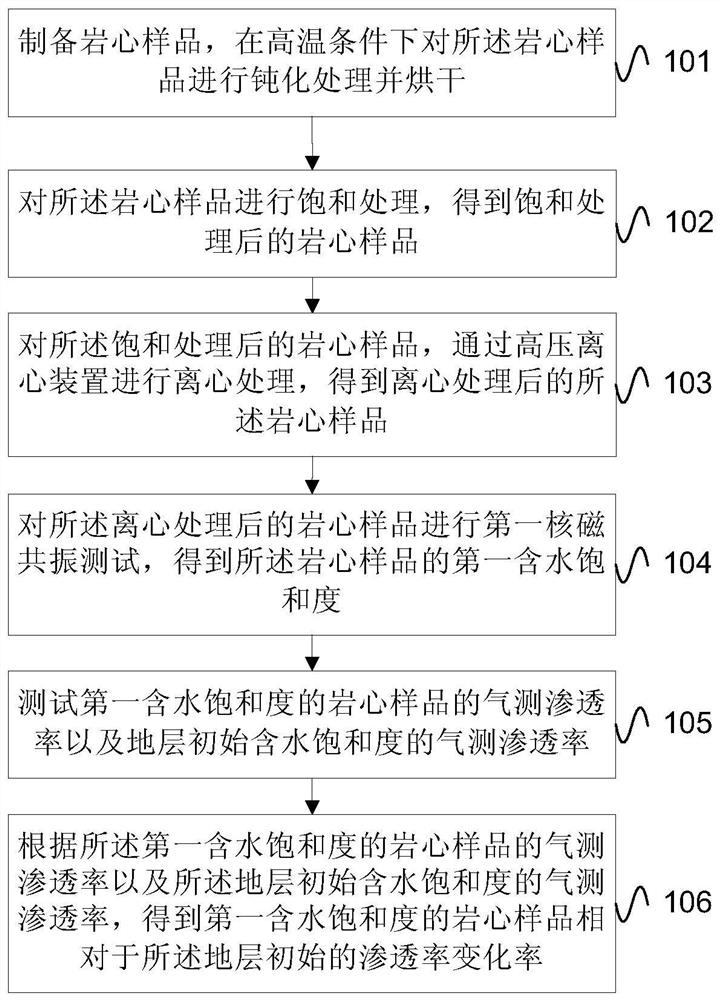

[0047] figure 1 It is the flow chart of Example 1 of the tight sandstone water lock damage evaluation test method of the present invention, as figure 1 As shown, the method of this embodiment may include:

[0048] Step 101, preparing rock core samples, performing passivation treatment and drying on the rock core samples under high temperature conditions.

[0049] In this embodiment, core samples are obtained in the direction of initial formation fluid flow through wellbore coring. Specifically, by drilling the plunger, the core sample is obtained in the initial reservoir fluid flow direction of the formation. The diameter of the sample is generally 2.5 cm, and its length is not less than 1.5 times the diameter. When the salinity of the formation water is higher than 20000mg / L or the formation water data is unknown, the prepared core samples need to be desalted with reagents such as methanol.

[0050] In this embodiment, after the core sample is prepared, passivation treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com