Diaphragm capable of improving sulfur content of positive electrode of lithium-sulfur battery, preparation method and application of diaphragm

A lithium-sulfur battery and sulfur content technology, applied in the application of lithium-sulfur batteries, the field of preparation of lithium-sulfur battery separators, can solve the problems of complex preparation process and process, unfavorable application, etc., and achieve the effect of inhibiting the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] The first step, preparation of carbon material-coated separator

[0029] The coating material and the binder PVD are dissolved in an appropriate amount of N-methylpyrrolidone (NMP) solvent according to the mass ratio of 8:2 and mixed uniformly to prepare a slurry; the slurry is coated on a commercial polypropylene diaphragm at 60°C Vacuum-dried for 12 hours, and punched into small discs with a diameter of 16 mm with a tablet press to obtain a carbon material-coated separator. The diaphragm is named Carbon Coated Diaphragm.

[0030] The coating material includes carbon black or other carbon materials, wherein the other carbon materials include graphite, carbon nanotubes, graphene and the like.

[0031] The second step is to prepare a separator with a dense membrane, that is, an SEI membrane.

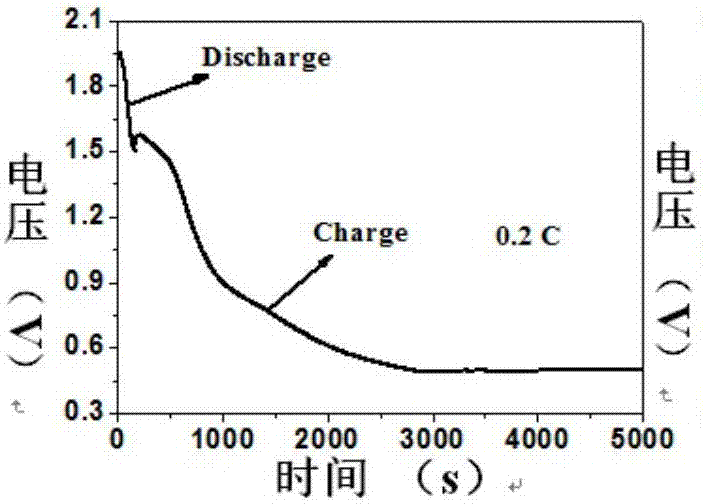

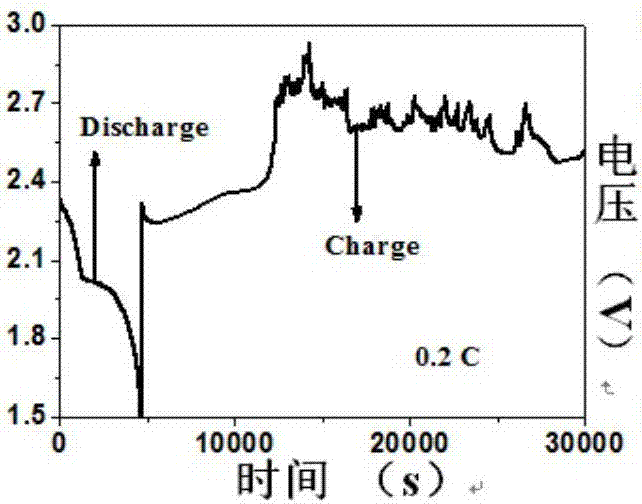

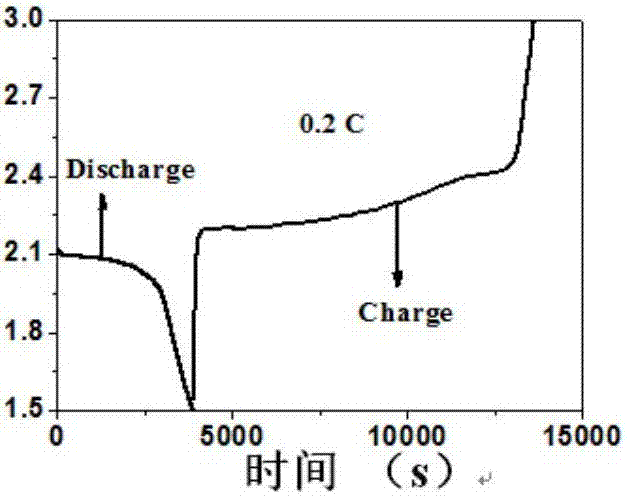

[0032] The carbon material-coated separator prepared in the first step and the lithium sheet are used to form a button battery. The coated carbon layer is used as the positive el...

Embodiment example 2

[0044] The first step, preparation of carbon material-coated separator

[0045] The coating material and the binder PVD are dissolved in an appropriate amount of N-methylpyrrolidone (NMP) solvent according to the mass ratio of 7:3 and mixed uniformly to prepare a slurry; the slurry is coated on a commercial polypropylene diaphragm at 50°C Vacuum-dried for 24 hours, and punched into small discs with a diameter of 16 mm by a tablet press to obtain a carbon material-coated separator. The diaphragm is named Carbon Coated Diaphragm.

[0046] The coating material includes carbon black or other carbon materials, wherein the other carbon materials include graphite, carbon nanotubes, graphene and the like.

[0047] The second step is to prepare a separator with a dense membrane, that is, an SEI membrane.

[0048] The carbon material-coated separator prepared in the first step and the lithium sheet are used to form a button battery. The coated carbon layer is used as the positive elec...

Embodiment example 3

[0052] The first step, preparation of carbon material-coated separator

[0053] The coating material and the binder PVD are dissolved in an appropriate amount of N-methylpyrrolidone (NMP) solvent according to the mass ratio of 8:2 and mixed uniformly to prepare a slurry; the slurry is coated on a commercial polypropylene diaphragm, 55°C Vacuum-dried for 16 hours, and punched into small discs with a diameter of 16 mm with a tablet press to obtain a carbon material-coated separator. The diaphragm is named Carbon Coated Diaphragm.

[0054] The coating material includes carbon black or other carbon materials, wherein the other carbon materials include graphite, carbon nanotubes, graphene and the like.

[0055] The second step is to prepare a separator with a dense membrane, that is, an SEI membrane.

[0056] The carbon material-coated separator prepared in the first step and the lithium sheet are used to form a button battery. The coated carbon layer is used as the positive elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com