Tin-based high-resistance film coating liquid, preparation method thereof and preparation method of tin-based high-resistance film

A technology of large resistance and coating solution, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as occlusion, affecting touch effect, and difficulty in realizing touch effect, so as to reduce the large resistance The effect of resistance change, stability, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The application also provides a preparation method for a tin-based high-resistance thin film coating solution, comprising the following steps:

[0035] After mixing water, ethanol and a dispersant, adding a tin-based alloy, adding a thickener, and stirring to obtain a tin-based high-resistance thin-film coating solution.

[0036] The preparation sequence of the above-mentioned tin-based high-resistance thin film coating solution can ensure good uniformity of the thin film. During the above mixing process, the whole process is carried out under stirring; the stirring speed is 100-2000 rpm, and the stirring time is 60-120 min.

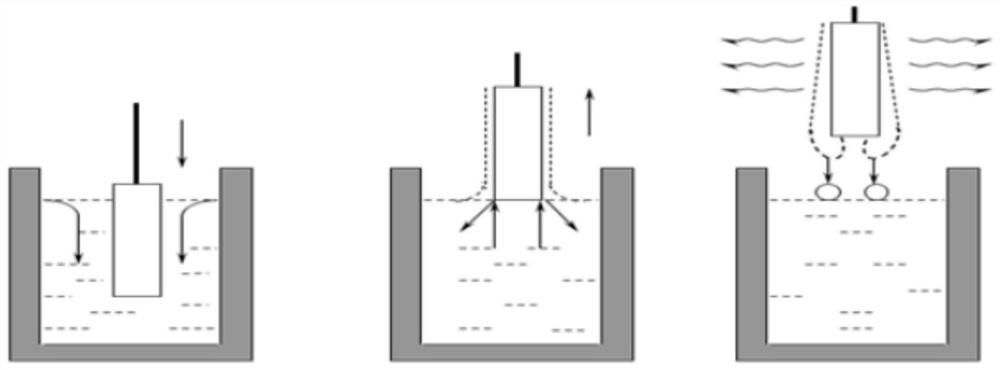

[0037] The present application also provides a method for preparing a tin-based high-resistance thin film, which uses the dipping and pulling method to immerse the entire cleaned base substrate in the coating solution, and then immerses the entire cleaned substrate in the coating solution at a controlled uniform speed. The substrate is pulled out...

Embodiment 1

[0051] Preparation of coating solution 1: Mix 45 parts by weight of water, 30 parts by weight of ethanol, and 8 parts by weight of dispersant with a stirring speed of 300 rpm, then add 7 parts by weight of tin-based alloy, and finally add 10 parts by weight of thickener, stirred for 70min; tin-based alloys include 70wt% tin, 30wt% aluminium, zinc, antimony and niobium;

[0052] Preparation of coating solution 2: Mix 56 parts by weight of water, 23 parts by weight of ethanol, and 7 parts by weight of dispersant with a stirring speed of 500 rpm, then add 8 parts by weight of tin-based alloy, and finally add 6 parts by weight of thickener, stirred for 90min; tin-based alloys include 80wt% tin, 20wt% aluminium, zinc and antimony;

[0053] Preparation of coating solution 3: Mix 60 parts by weight of water, 20 parts by weight of ethanol, and 6 parts by weight of dispersant with a stirring speed of 200 rpm, then add 10 parts by weight of tin-based alloy, and finally add 4 parts by we...

Embodiment 2

[0059]Operation before cleaning is identical with embodiment 1;

[0060] Vacuum absorb the cleaned PET substrate on the surface of the workbench, the vacuum pressure is 0.8Pa; the PET substrate enters the coating solution 1 to pull the coating, and then the rotary table automatically rotates the coating solution 2 to the bottom of the substrate, and then the substrate descends into Coating solution 2 pulls the coating, and the subsequent film layers are completed in sequence; the pulling speed is 150 μm / s; the immersion time is 150s; the number of coating times is 5 times; the solution temperature is 22°C;

[0061] After the coating is completed, let it dry naturally for 40 minutes at a temperature of 28°C and a film thickness of 150 μm;

[0062] Put the air-dried substrate into a vacuum drying oven, raise it to 100°C at 5°C / min and keep it for 1.5 hours, then raise the temperature to 250°C and keep it for 45 minutes to dry, then naturally drop to room temperature, the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com