Mini white-light laser and manufacture method thereof

A laser and white light technology, applied in the field of lasers, can solve the problems of complex adjustment scheme and huge overall volume, and achieve the effect of simple and flexible adjustment method, high brightness and good coherence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

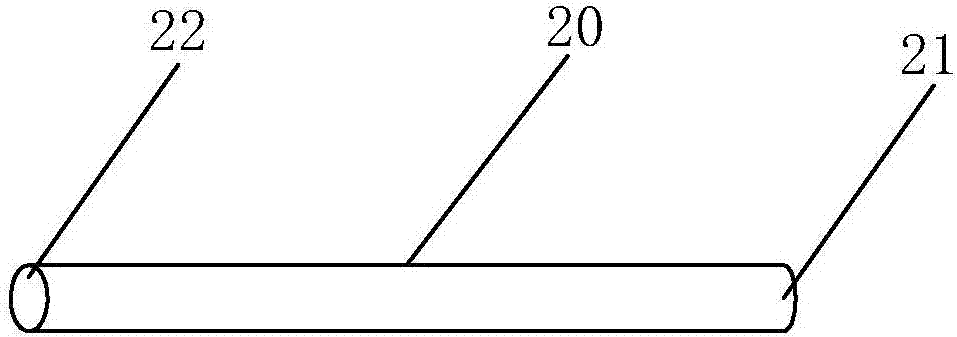

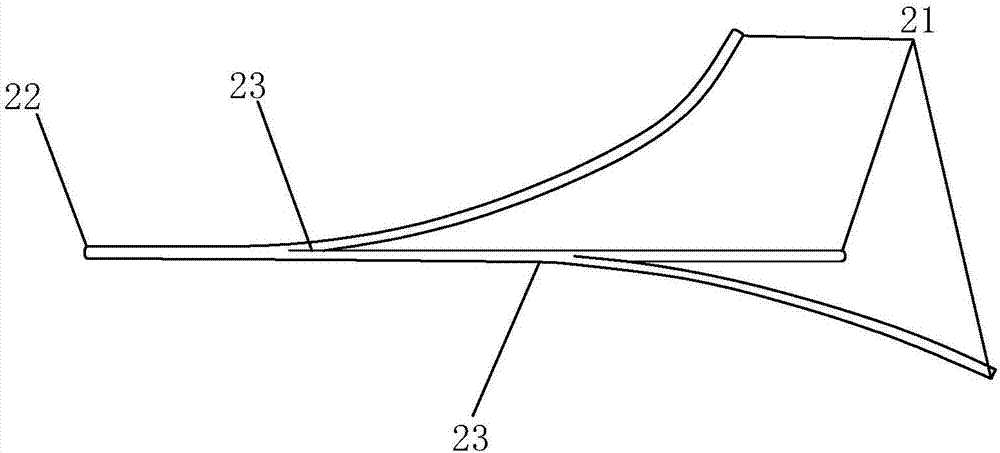

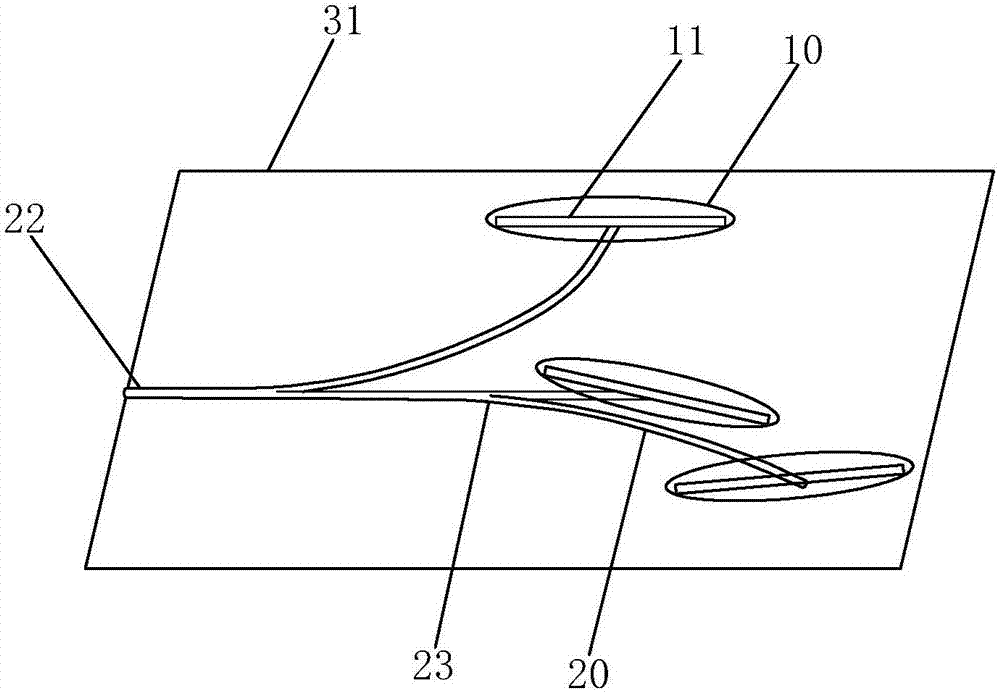

[0025] Figure 1 to Figure 4 , a miniature white light laser, including a microfluidic chip 30 and three laser diodes 10 and three micron optical waveguides 20 packaged inside. The input ends 21 of the three micron optical waveguides 20 are located on the light-emitting surfaces 11 of the active regions of the three laser diodes 10 in one-to-one correspondence. One of the micron optical waveguides 20 serves as a backbone and is coupled with the output ends 22 of other micron optical waveguides 20 to synthesize white light, and its output end 22 is used as a white light output end.

[0026] Specifically, three laser diodes 10 respectively output red light, green light and blue light, and three micron optical waveguides 20 are coupled to form a 1×3 branch structure, including three input terminals 21 , one output terminal 22 and two coupling regions 23 . The micron optical waveguide 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com