Preparation method of catalytic cracking regeneration flue gas sulfur transfer agent

A technology for sulfur transfer agent and flue gas regeneration, applied in catalytic cracking, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problems of the mechanical strength and reduction and regeneration ability of sulfur transfer agent, and achieve guaranteed performance, Improve the wear index and reduce the effect of poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Beat 6.11 kg of dolomite powder, and adjust the pH of the slurry to 3 with hydrochloric acid.

[0039] (2) Add 3.08 kilograms of pseudo-boehmite to the slurry in (1)

[0040] (3) Add 4.29LMgCl successively to the slurry in (2) 2 solution, 2.00LFeCl 2 solution, 0.21 kg of MnO, stirred.

[0041] (4) Spray-dry the above slurry to obtain a sulfur transfer agent, which is designated as sample LJ-1.

Embodiment 2

[0043] (1) Beat 4.44 kg of dolomitic ore powder, and adjust the pH of the slurry to 2.5 with hydrochloric acid.

[0044] (2) Add 4.62 kilograms of pseudo-boehmite to the slurry in (1)

[0045] (3) Add 5.71LMgCl successively to the slurry in (2) 2 solution, 1.50LFeCl 2 solution, 0.42 kg of MnO, stirred.

[0046] (4) Spray-dry the above slurry to obtain a sulfur transfer agent, which is designated as sample LJ-2.

Embodiment 3

[0048] (1) Beat 6.67 kg of dolomite powder, and adjust the pH of the slurry to 3 with hydrochloric acid.

[0049] (2) Add 3.85 kilograms of pseudo-boehmite to the slurry in (1)

[0050] (3) Add 2.86LMgCl successively to the slurry in (2) 2 solution, 1.00L FeCl 2 solution, 0.11 kg of MnO, stirred.

[0051] (4) Spray-dry the above slurry to obtain a sulfur transfer agent, which is designated as sample LJ-3.

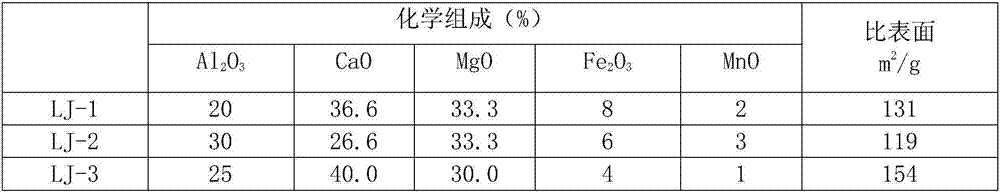

[0052] The analysis result of sulfur transfer agent in the example is as follows

[0053] The analysis result of table 1 sulfur transfer agent

[0054]

[0055] Catalyst Aging: The prepared catalyst was hydrothermally treated at 800° C. and 100% steam for 17 hours before being used.

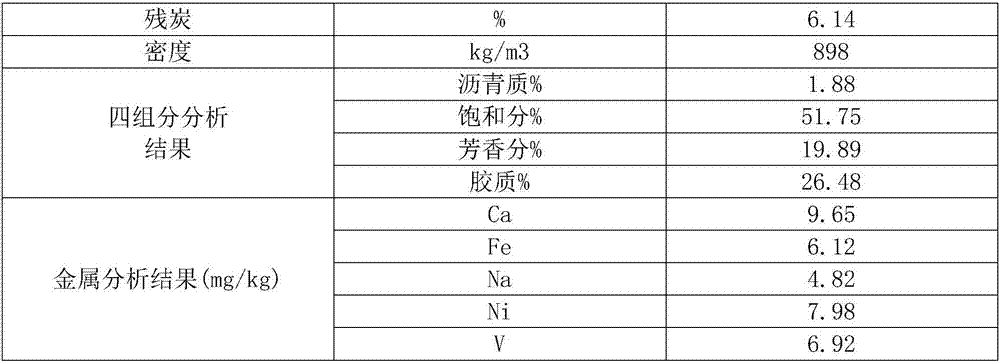

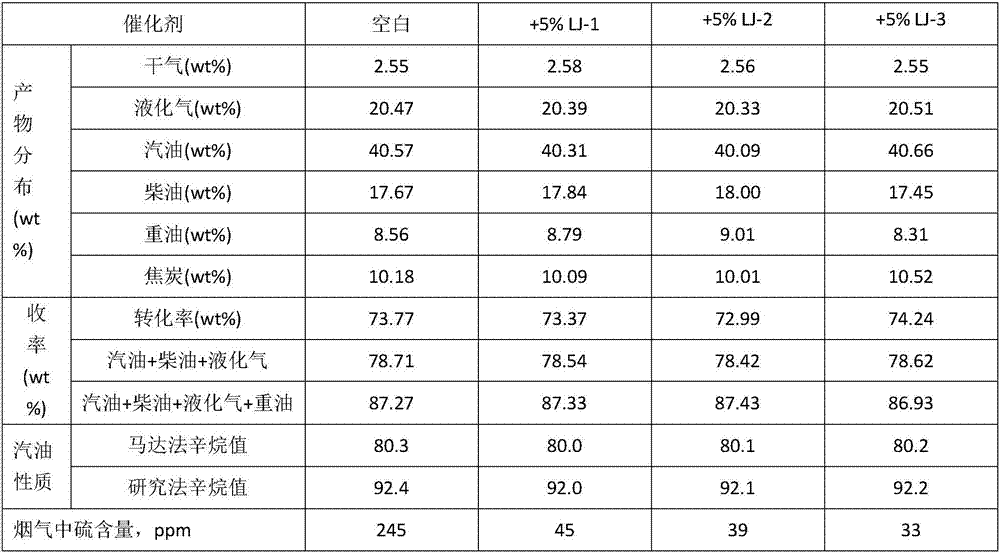

[0056] Catalyst evaluation: The evaluation of catalyst was carried out on FFB fixed fluidized bed. The raw material oil is mixed raw material oil from a refinery. The properties of the raw material are shown in Table 2. The main agent is AIC-950, produced by Qingdao Huicheng Environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com