Wood-plastic composite product compression moulding and pre-spreading method and wood-plastic composite product compression moulding and pre-spreading system

A wood-plastic composite material and molding technology, which is applied in the field of material molding, can solve problems such as difficult molding, and achieve the effects of low cost, easy manipulation, and good molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

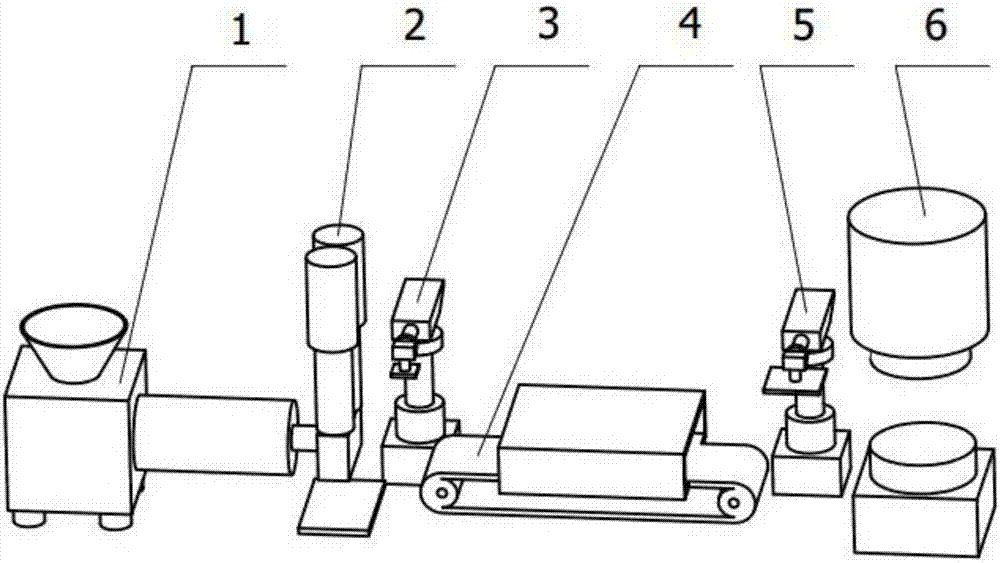

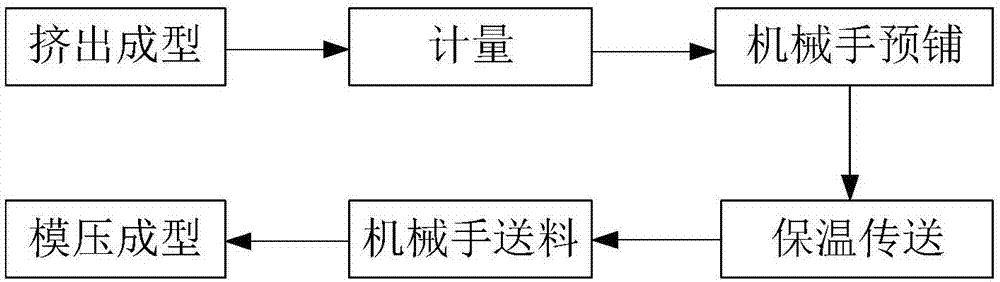

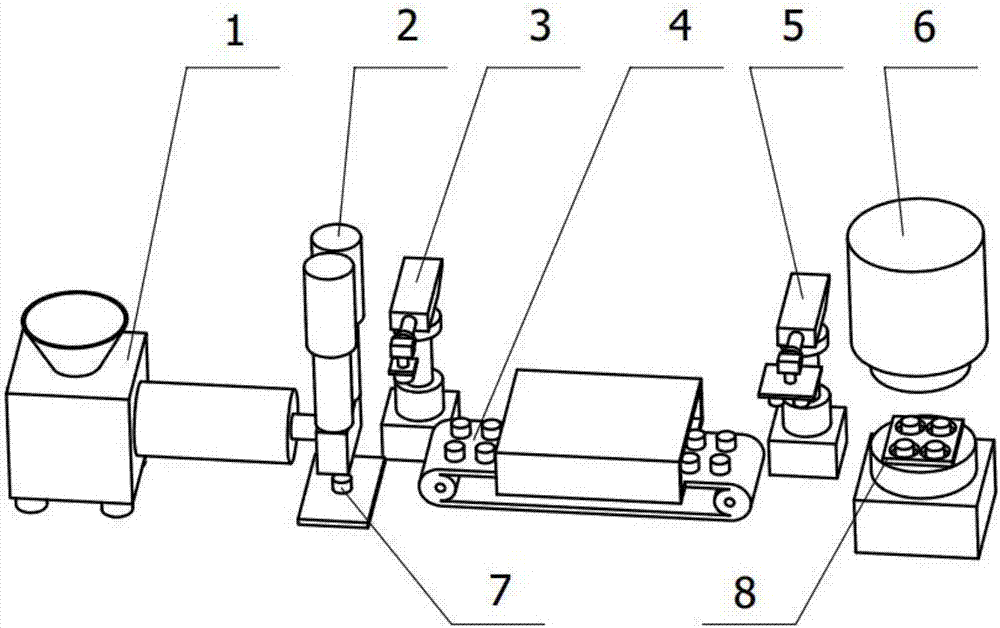

[0024] A wood-plastic composite material product molding pre-laying method and system. The method and system are mainly used in the wood-plastic composite material molding process with multiple cavities in one mold and large-scale products. The conveyor belt insulates the wood-plastic composite material block during the conveying process, which ensures the consistency of the temperature of the wood-plastic composite material block entering each cavity of the molding machine, improves its molding performance, and reduces the occurrence of defective and inferior products; In the processing of large-sized products, a single large-sized block is replaced by multiple smaller-sized blocks scattered around, and the optimal placement quantity of each block is simulated and analyzed on the computer in advance. The corresponding position solves the problem that large-sized products are difficult to form when using a single large-size block, which can effectively reduce its product rate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com