Hose type circulating integrated denitrification reactor and method

A reactor and circulation technology, applied in the field of integrated reactors, can solve the problems that the reaction system is not easy to inhibit or eliminate nitrifying bacteria, and the reaction system is not easy to balance the acid and alkali, so as to reduce the loss, ensure efficient operation, and simple reaction device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific drawings and specific embodiments. Unless otherwise stated or conflicted, any combination of the preferred embodiments can be made.

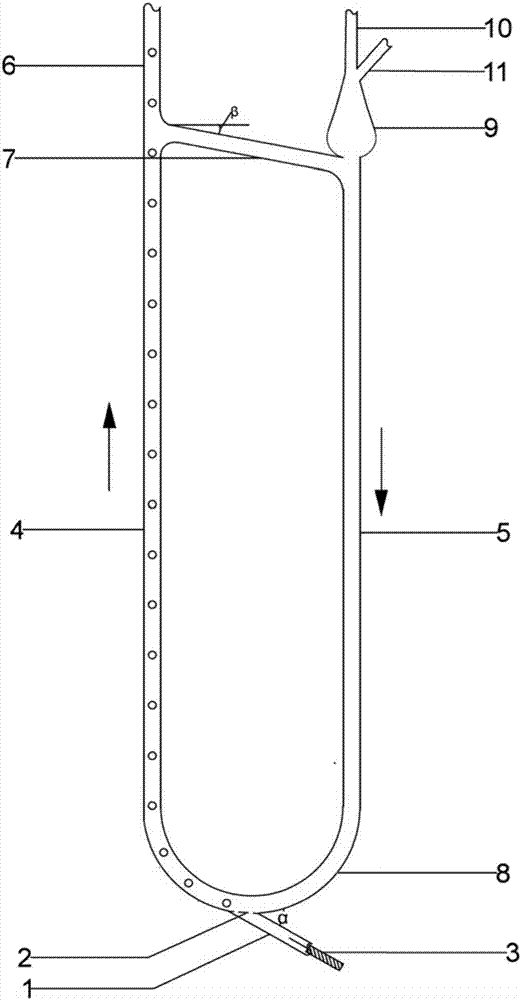

[0018] Such as figure 1 As shown, the hose-type circulating integrated denitrification reactor is installed vertically and is divided into water distribution area I, reaction area II, and separation area III; water distribution area I includes water inlet pipe 1 and circular filter screen 2 , gas supply needle 3; reaction zone II includes aerobic section 4, anoxic section 5, exhaust pipe 6, upper guide tube 7, lower guide tube 8; separation zone III includes three-phase separator 9, air pressure balance tube 10. Backflow water outlet 11. The main body of the reactor is a ring-shaped hose, which is connected end-to-end by an aerobic section 4, an upper flow pipe 7, an anoxic section 5, and a lower flow pipe 8.

[0019] In the water distribution area I, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com