Opposite-opening totally-closed melt confined flow induced nucleation semi-solid slurry preparation device

A technology for semi-solid slurry and preparation device, applied in the field of material processing, can solve the problems of high cost, gap between production efficiency and product quality, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

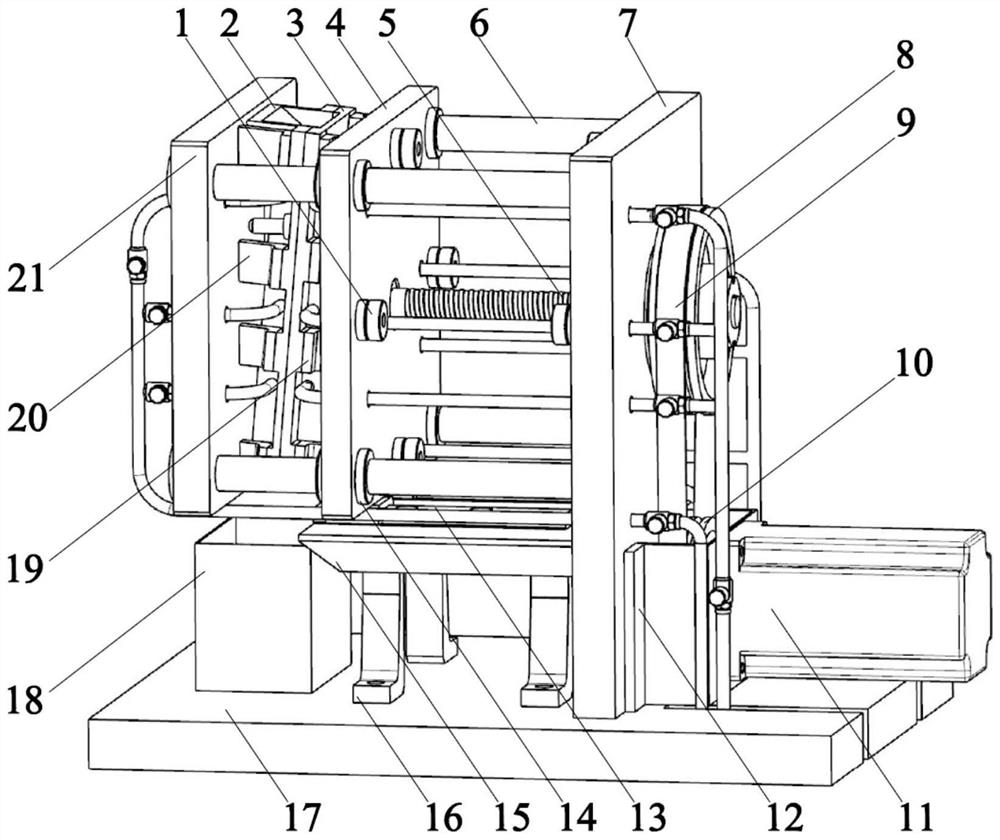

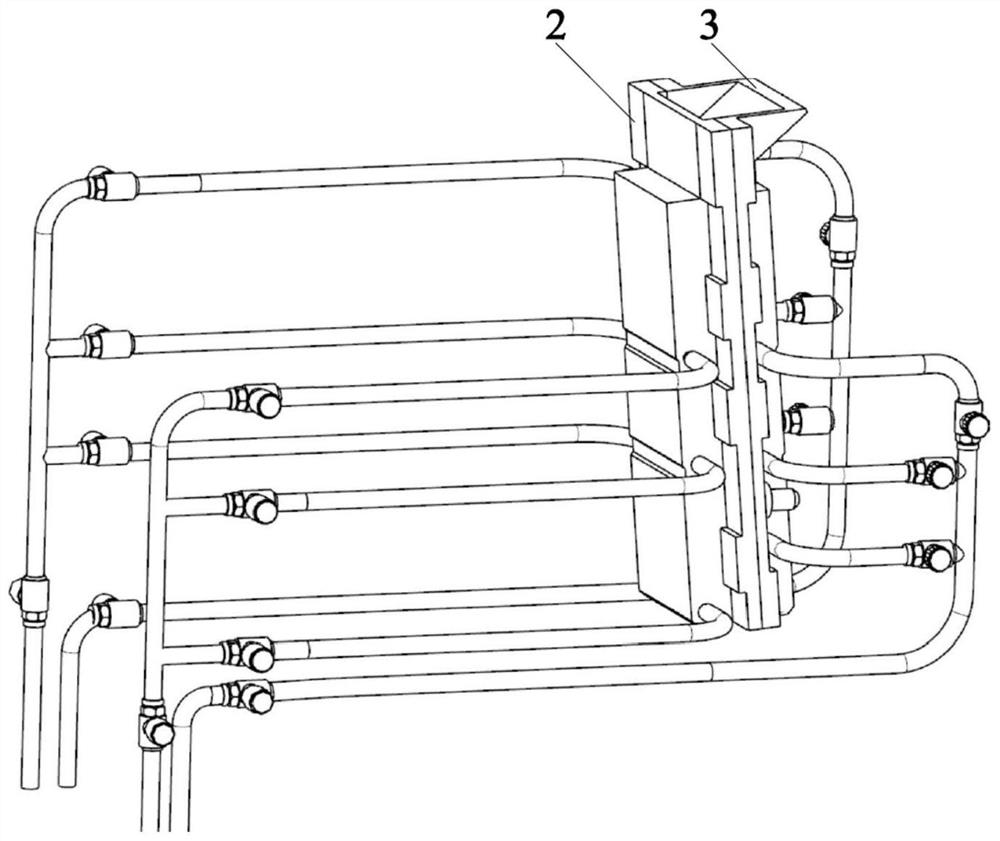

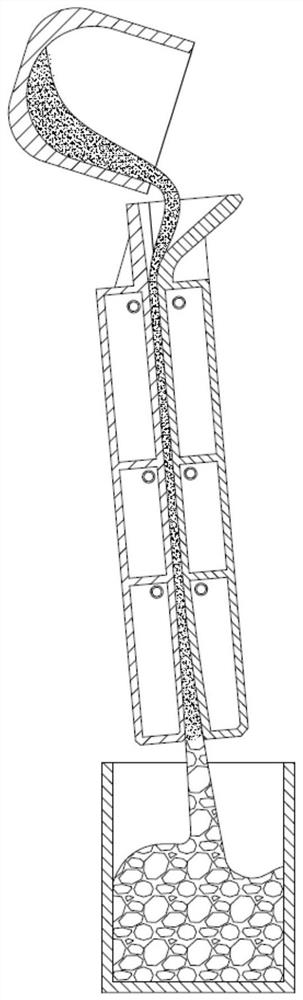

[0032] A split-type fully enclosed melt-confined flow-induced nucleation semi-solid slurry preparation device, such as Figure 1~2 As shown, the upper cooling plate 2 and the lower cooling plate 3 are included. After the upper cooling plate 2 and the lower cooling plate 3 are combined, a melt-constrained flow-induced nucleation channel is formed between the two. The upper end forms a feed port, and the lower end forms a The discharge port is provided with a receiving crucible 18 directly below the discharge port;

[0033] The upper cooling plate 2 is provided with a plurality of water tanks from top to bottom, and each water tank is correspondingly provided with a water inlet pipe and a water outlet pipe, and each water inlet pipe and water outlet pipe are provided with a flow regulating valve. The water pipes are all connected with the main water inlet pipe, and the main water inlet pipe is equipped with a water flow master regulating valve. The setting of the water tank, wa...

Embodiment approach 1

[0035] The power mechanism of the present invention is used to drive the movable plate 4 to move horizontally, and any power mechanism such as a hydraulic rod can be used. As a preferred embodiment of the present invention one: the power mechanism includes a frequency modulation motor 11, a small pulley 10, a large Pulley 8, belt 9, ball screw 5, frequency modulation motor 11 is connected with small pulley 10, small pulley 10 is connected with large pulley 8 through belt 9, large pulley 8 is connected with movable plate 4 through ball screw 5 , the frequency modulation motor 11 is rotated to drive the movable plate 4 to move horizontally. Wherein, the movable plate 4 is placed on the guide rail workbench 15, and the guide rail workbench 15 is provided with a track 13 for the movable plate 4 to move; one side of the guide rail workbench 15 is provided with a fixed seat 7, and the fixed seat 7 is used to fix the frequency modulation motor 11. The small pulley 10 and the large pu...

Embodiment approach 2

[0036] As the second preferred embodiment of the present invention: four guide pillars 6 are arranged on the movable plate 4 of the present embodiment, one end of the guide pillar 6 is fixedly connected with the fixed plate 21, the other end is fixedly connected with the fixed seat 7, and the middle passes through The movable plate 4 is provided with a guide sleeve 14 at the joint between the movable plate 4 and the guide post 6, and the movable plate 4 can move back and forth on the guide post 6; the centering of the opening and closing process can be ensured through the clearance fit between the guide post 6 and the guide sleeve 14 The bottom of the movable plate 4 is provided with a movable plate motion guide rail 13 to support the movable plate 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com