Framework for in-situ casting, preparation method and wall body made of framework

A skeleton and cast-in-place technology, applied to walls, building components, buildings, etc., can solve problems such as waste of energy, labor and water, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

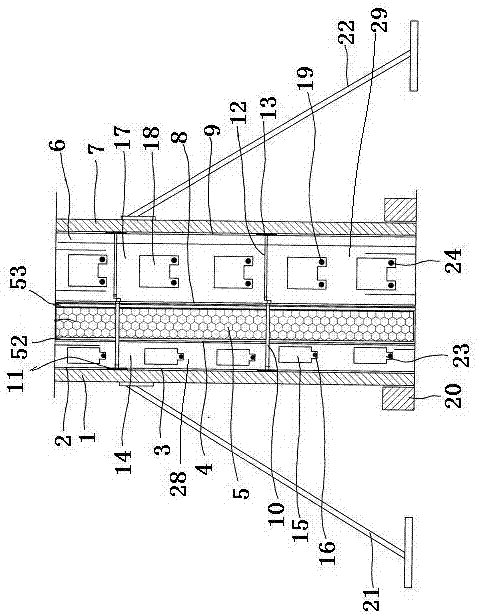

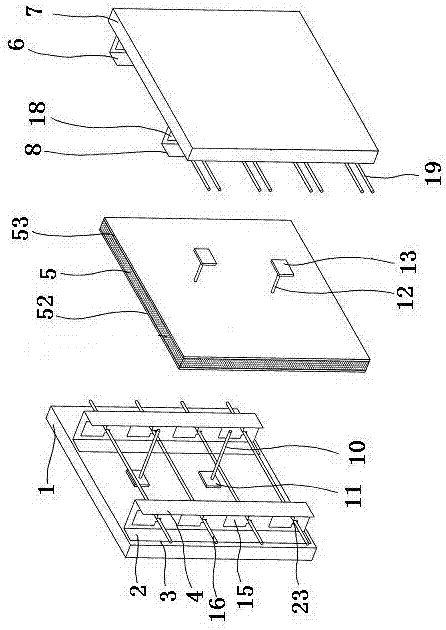

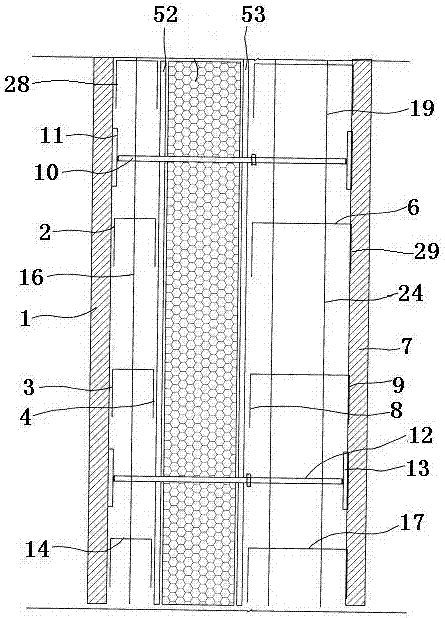

[0063] The structure and use principle of a cast-in-situ framework, a method for preparing a cast-in-situ framework, and a wall prepared by using a cast-in-situ framework of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

[0064] In order to express more clearly, the inside and outside described in the text are relative to the entire cast-in-place framework, that is, the side of a cast-in-place framework with the first membrane shell is defined as the outside, with the second membrane shell The side is defined as the inside.

[0065] Such as figure 1 , figure 2 with image 3 As shown, a cast-in-situ skeleton of the present invention includes a first membrane shell 1 located at the outermost side. A first keel 2 containing at least two parallel bonding planes is provided on the inner side of the first membrane shell 1, and the first keel 2 is located The outer first bonding plane 3 is bonded to the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com