Track leveling control system for drill carriage and adjusting control method

A control system and crawler technology, applied in fluid pressure actuators, servo motors, servo meter circuits, etc., can solve the problems of inaccurate leveling, inconvenience for drilling rig operators, and large space occupation, and achieve flexible operation, The effect of humanized operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

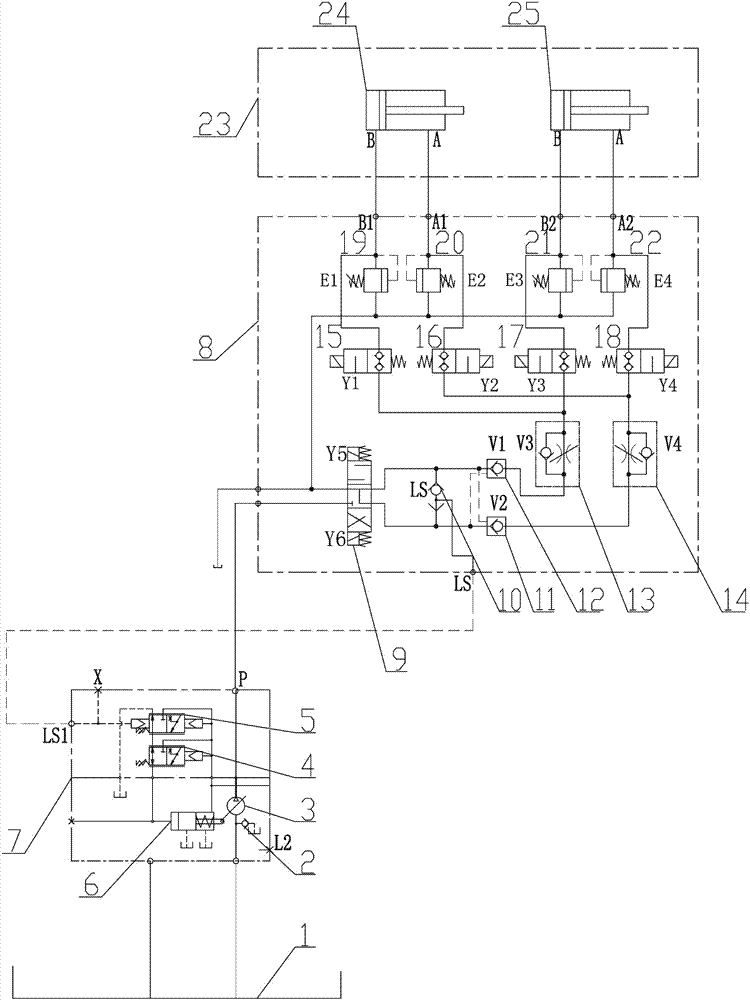

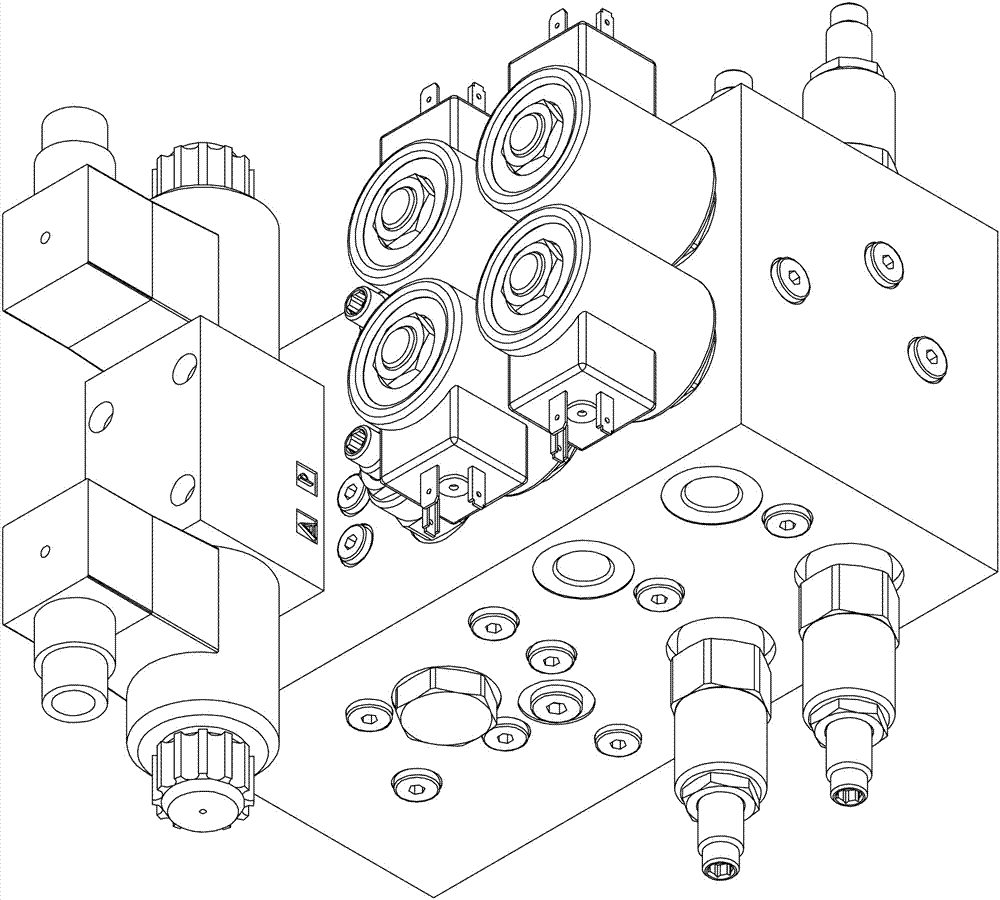

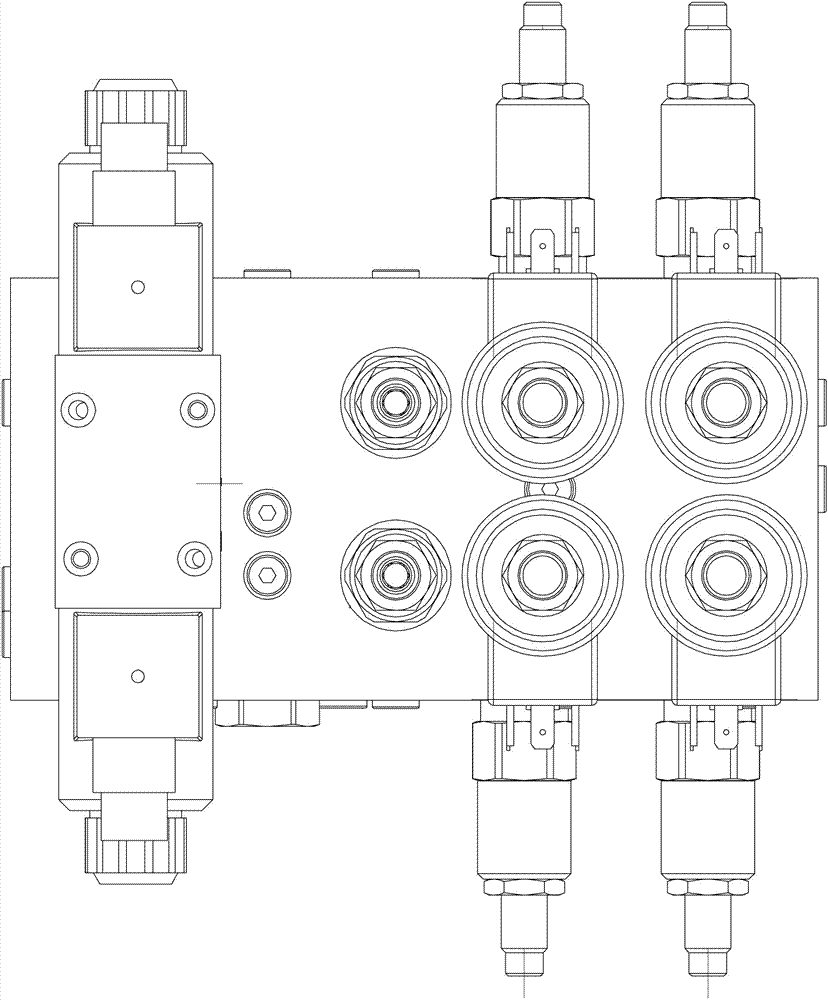

[0028] Such as Figure 1-6 , a track leveling control system of a drilling rig, which includes a power mechanism 7 , the power mechanism 7 is connected to a track leveling valve group 8 , and the track leveling valve group 8 is connected to an actuator 23 . The hydraulic power provided by the power mechanism 7 can provide power for the track leveling system, the action of the corresponding solenoid valve can be controlled by the track leveling valve group 8 , and then different actions can be implemented, and the corresponding action can be realized by the actuator 23 .

[0029] Further, the power mechanism includes a variable displacement pump 3, and the variable displacement pump 3 is connected to two parallel first load pressure sensitive control valves 4 and second load pressure sensitive control valves 5; the oil inlet pipe of the variable displacement pump 3 is connected to the The oil tank 1 is connected and a check valve 2 is connected in parallel on the oil inlet pipe...

Embodiment 2

[0035] Using any one of the track leveling control system adjustment control methods, it is characterized in that it includes:

[0036] Step 1: By supplying power to Y1 / Y2 / Y3 / Y4 of the four two-way stop solenoid valves 15, 16, 17, 18, Y5 / Y6 of the three-position four-way electromagnetic reversing valve 9 is not powered, so that the actuator The left leveling oil cylinder 24 and the right leveling oil cylinder 25 of 23 are connected. When the road surface is uneven during walking, one oil cylinder is compressed, and the oil fluid flows to the other oil cylinder through the track leveling valve group 8, and the other Only the oil cylinder is stretched out accordingly, so that the floating is the body balance;

[0037] Step 2: By supplying power to Y1 / Y2 of the two-way cut-off solenoid valves 15 and 16, and Y5 or Y6 of the three-position four-way electromagnetic reversing valve 9, the left leveling cylinder 24 can independently expand and contract;

[0038] Step 3: By supplying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com