Capacitive liquid level detection method

A liquid level detection and capacitive technology, which is applied in the field of capacitive liquid level detection, can solve the problems of high production cost, inconvenient system maintenance and repair, and limited service life of reed switch, so as to reduce maintenance time cost and improve use economy performance, the effect of easy bonding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A capacitive liquid level detection method in this embodiment, a capacitive liquid level detection method, uses liquid to fill a capacitive signal device composed of polar tubes to change the capacitance value of the capacitive signal device, and then the capacitance Value changes to determine the liquid level.

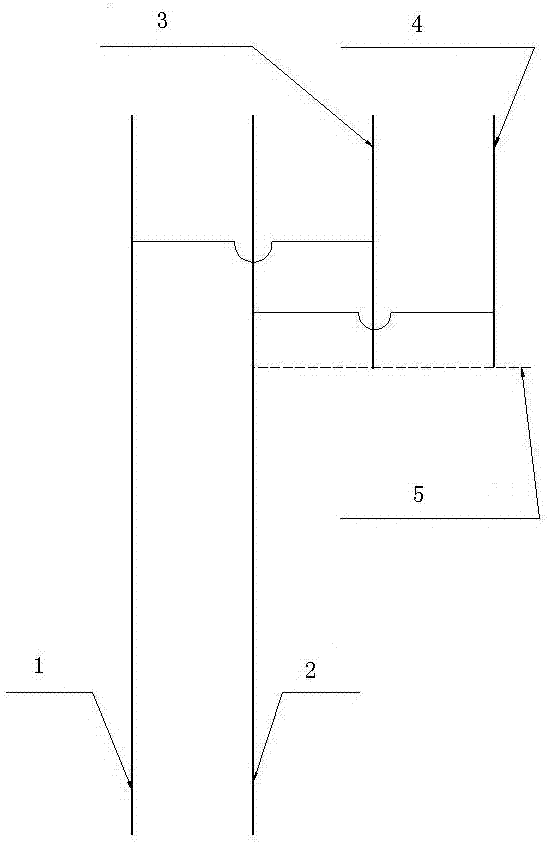

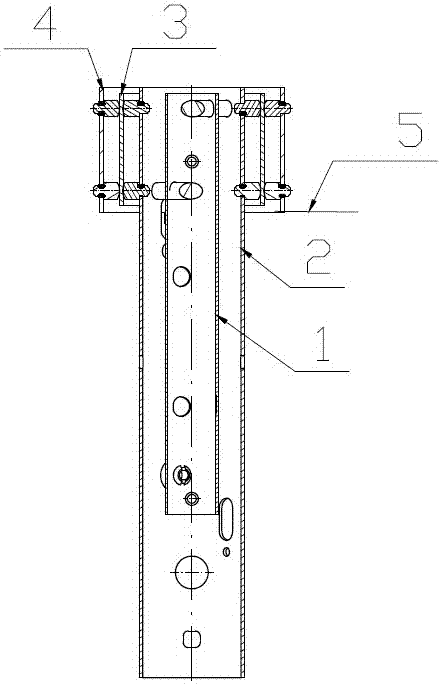

[0020] Such as figure 1 with figure 2 As shown: the capacitive annunciator includes a capacitive tube body and a signal prompter electrically connected to the capacitive tube body, and the capacitive tube body includes an inner tube 1, an outer tube 2, and an inner signal tube 3 that are sequentially set from the inside to the outside , the outer signal tube 4; the inner tube 1 is electrically connected to the inner signal tube 3 to form a capacitor N pole, and the outer tube 2 and the outer signal tube 4 are electrically connected to form a capacitor P pole; the inner signal tube 3 Consistent with the length of the outer signal tube 4, the length of the inn...

Embodiment 2

[0022] This embodiment is further optimized on the basis of Embodiment 1. The liquid level detection method of the capacitor composed of polar tubes specifically includes the following steps:

[0023] Step S1: Connect the inner signal tube 3 and the inner tube 1 together with wires to form one pole of the capacitor together as N pole; connect the outer signal tube 4 and the outer tube 2 together with wires to form the other pole of the capacitor together The pole is recorded as P pole.

[0024] Step S2: When the capacitive annunciator is used as a low fuel level alarm annunciator, fix the bottom of the inner tube 1 and outer tube 2 to the bottom of the fuel tank. The initial state is that the four-layer tube of the annunciator is filled with fuel. When it gradually decreases, because the dielectric constant of fuel is greater than that of air, the capacitance value between the P pole and N pole decreases proportionally with the decrease of the liquid level. When the liquid lev...

Embodiment 3

[0029]A capacitive liquid level detection method in this embodiment uses liquid to fill a capacitive annunciator composed of polar tubes to change the capacitance value in the capacitive annunciator, and then judge the liquid level by the change of capacitance value. liquid level. Among them, the capacitive signal device includes a signal prompter with a capacitor tube body electrically connected to the capacitor tube body. The capacitor tube body includes an inner tube 1, an outer tube 2, an inner signal tube 3, and an outer signal tube that are sequentially set from inside to outside. Tube 4; the inner tube 1 is electrically connected to the inner signal tube 3 to form a capacitor N pole, and the outer tube 2 and the outer signal tube 4 are electrically connected to form a capacitor P pole; the inner signal tube 3 and the outer signal tube The tubes 4 have the same length, the inner tube 1 and the outer tube 2 have the same length, and the inner tube 1 is longer than the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com