Self-energy feeding type brake device for airplanes

A braking device and self-feeding energy technology, applied in the direction of aircraft braking arrangement, can solve the problems of volume, heat dissipation and reliability, high power density, heavy motor load, etc., and achieve easy thermal balance design, high reliability and high reliability. Maintainability and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

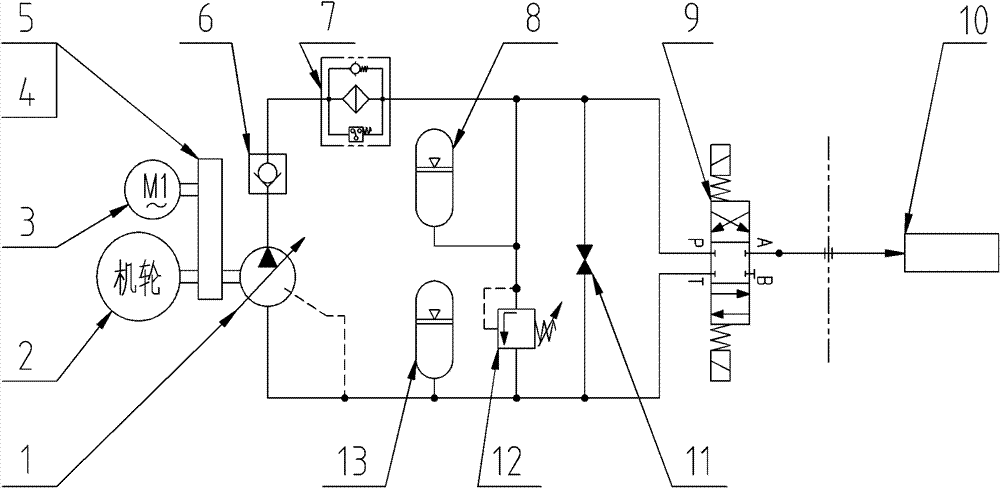

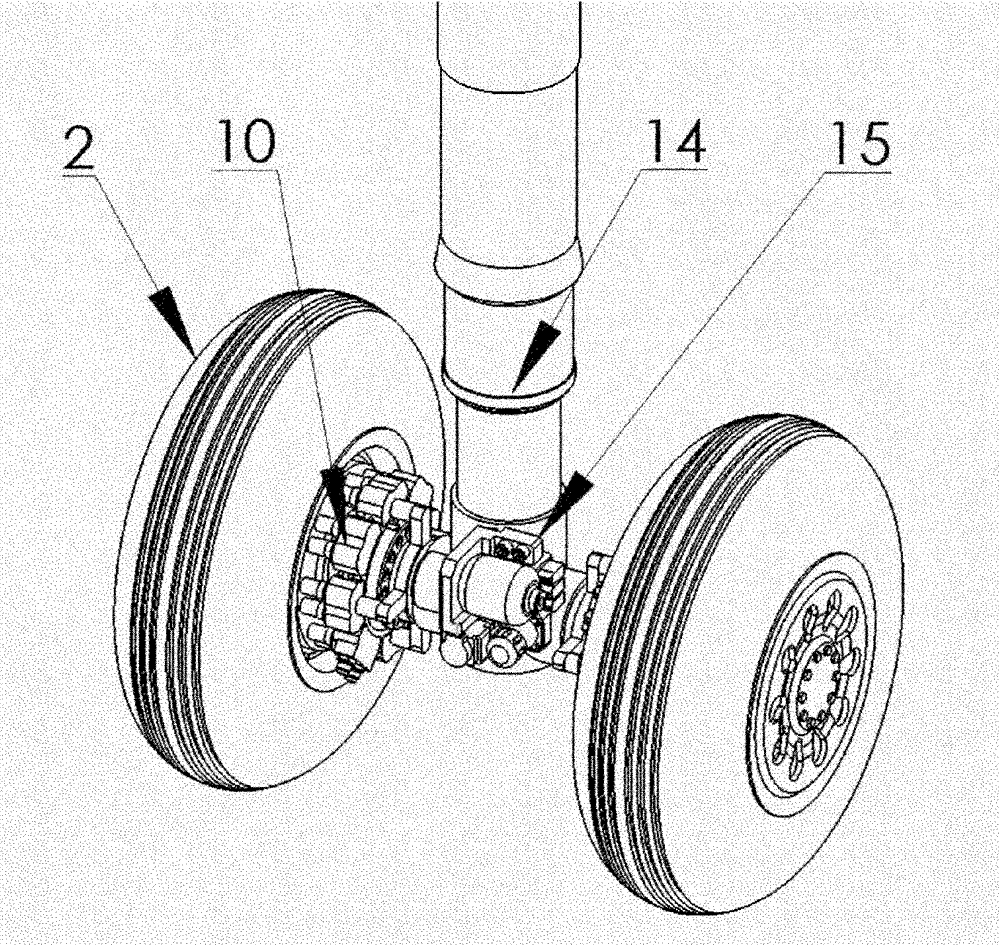

[0030] like figure 2 As shown, it is a schematic diagram of the actual installation of the aircraft self-feeding brake device according to the present invention. The hydraulic pump 1 adopts a constant pressure variable pump, and the input shaft of the constant pressure variable pump passes through the reducer 4 and the clutch 5 and then connects with the wheel 2 through gears. , The accumulator 8 adopts a diaphragm accumulator, and the fuel tank 13 adopts a pressurized fuel tank. The aircraft self-feeding brake device 15 is provided with an integrated integrated block, and all components (including hydraulic pump 1, auxiliary motor 3, speed reducer 4, electromagnetic clutch 5, check valve 6, high-pressure oil filter 7, accumulator 8, brake valve 9, bypass valve 11, overflow valve 12 and fuel tank 13) are all installed on the integrated block, self-feeding brake device 15 is installed on the aircraft landing gear 14, when the aircraft lands, the aircraft wheel 2 starts When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com