Semiconductor light emitting device and manufacturing method thereof

A technology of light-emitting devices and manufacturing methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to solve the problems of front light intensity and small light-emitting angle of semiconductor light-emitting devices, surface vulcanization, poor reliability, etc., and achieve simple structure, Strong anti-attenuation ability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

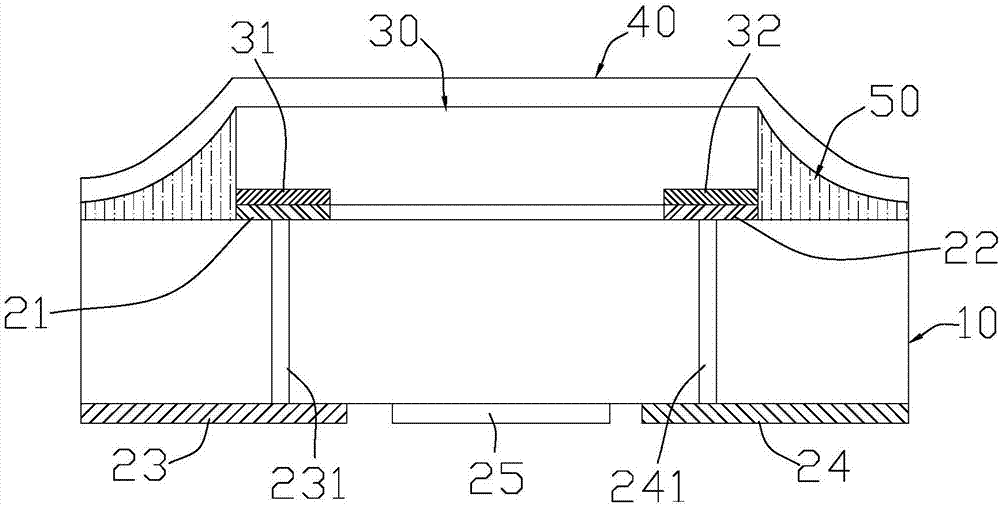

[0036] like figure 2 As shown, the semiconductor light emitting device of the first embodiment of the present invention includes a substrate 10, at least one anode pad 21 and at least one cathode pad 22 disposed on the substrate 10, and at least one semiconductor light emitting chip 30 disposed on the substrate 10. , the phosphor layer 40 that is arranged on the substrate 10 and wraps the semiconductor light-emitting chip 30, and the insulating layer 50 that is arranged on the inside of the phosphor layer 40 (towards the side of the substrate 10 and the semiconductor light-emitting chip 30); the positive electrode of the semiconductor light-emitting chip 30 31 and the negative electrode 32 are electrically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com