Series-mode nickel-metal hydride battery charging and discharging motor

A nickel-metal hydride battery and charge-discharger technology is applied in the field of series-connected nickel-metal hydride battery charge-dischargers, and can solve problems such as difficulty in ensuring the consistency of products produced in multiple batches, connection of stackers in logistics lines, and cumbersome batch production operations. Achieve the effect of good consistency, good safety and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

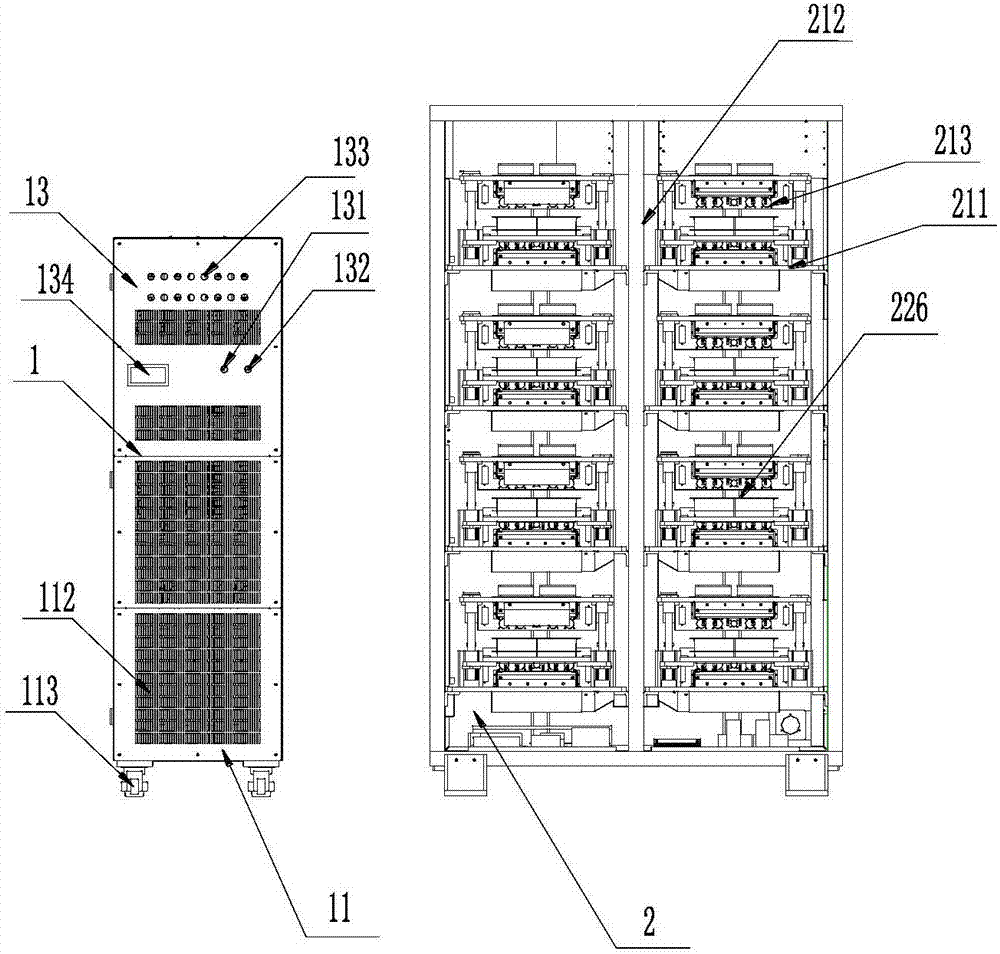

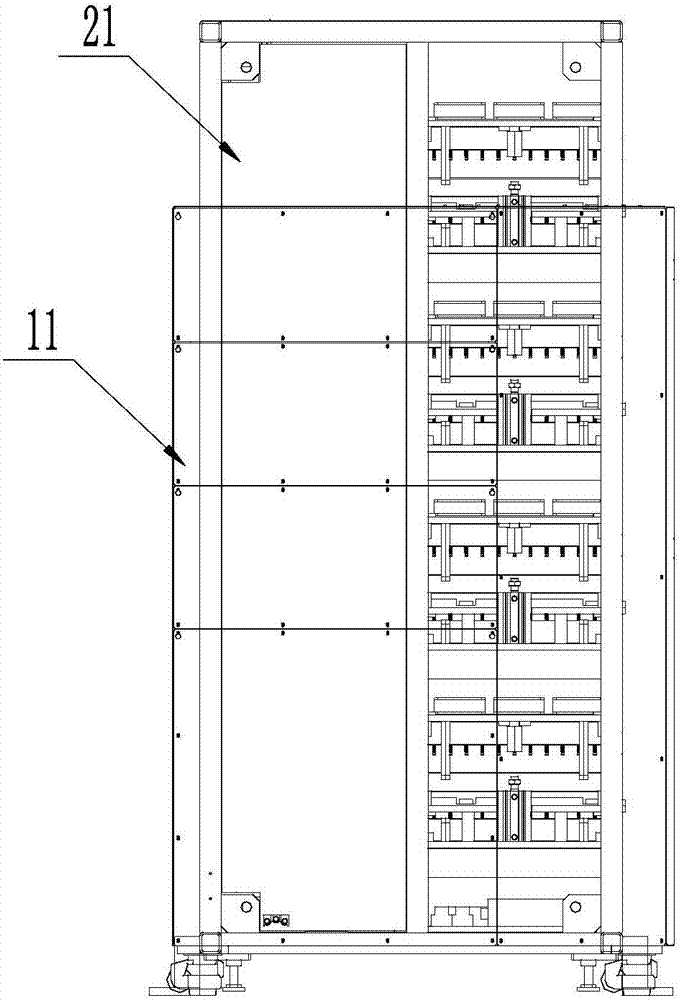

[0025] Embodiment 1 The series Ni-MH battery charge-discharge machine described in the present invention includes a charge-discharge unit 1 for charging and discharging the Ni-MH battery, a motion unit 2 for clamping the Ni-MH battery, and a unit for controlling the charge-discharge unit The general controller that works with motion unit, described charging and discharging unit 1 comprises power supply cabinet 11, charging and discharging power supply, power supply, power supply control board, alarm and cooling device 12, described charging and discharging power supply, power control board, alarm and the cooling device are installed inside the power cabinet, the control terminal of the charging and discharging power supply is electrically connected with the first signal transmission terminal of the power control board, the second signal transmission terminal of the power control board, the motion unit The control terminals of the main controller are electrically connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com