Propane dehydrogenation catalyst, and preparation method and application thereof

A technology for propane dehydrogenation and catalyst, which is applied to catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve problems such as reducing the content of Pt, and achieve the effects of improving olefin selectivity, favorable for dispersion and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

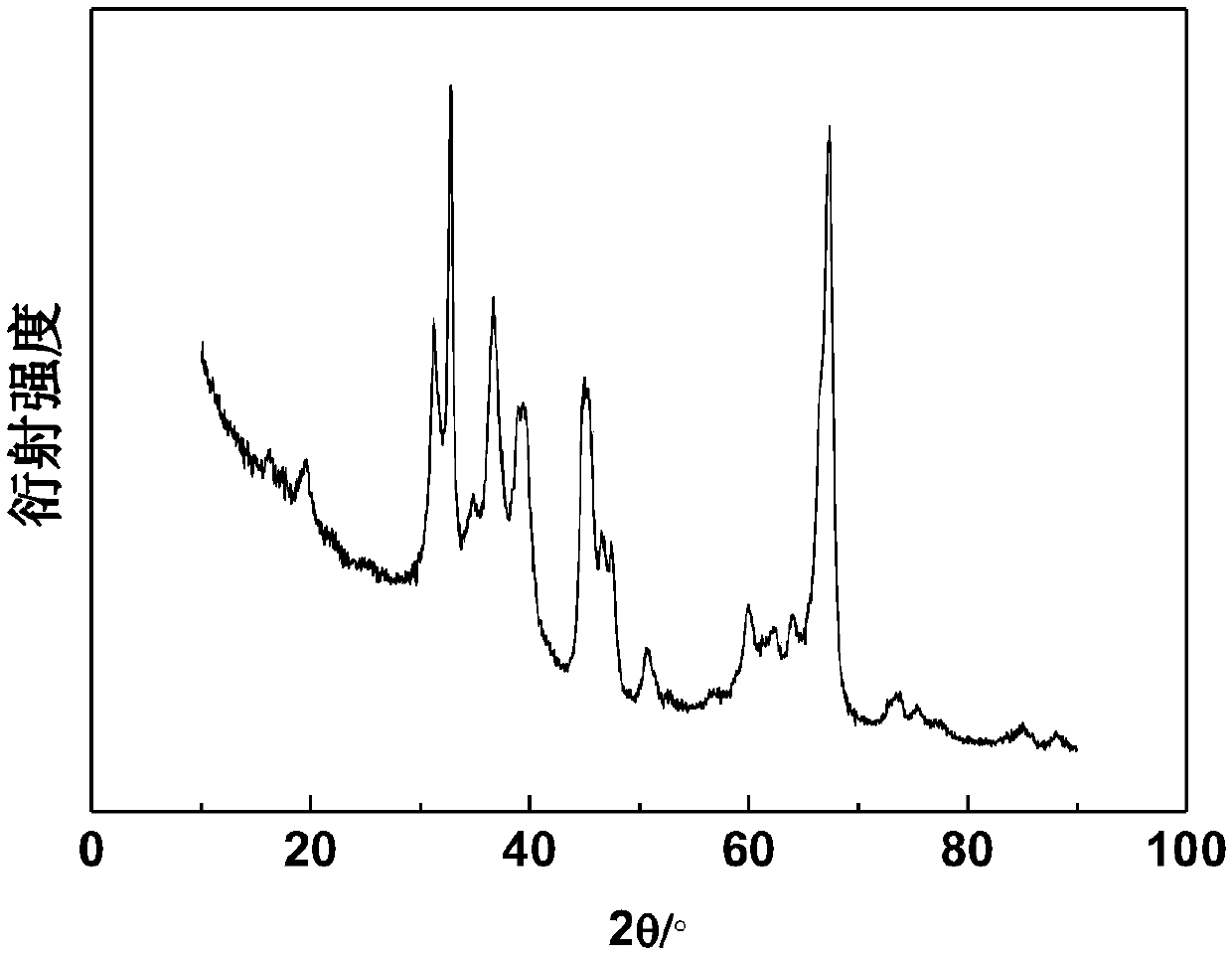

[0036] Weigh 4.0g and crush to 20-40 mesh θ-Al 2 o 3 Carrier particles (20-40 mesh particles, pore volume 0.49cm 3 / g, specific surface area 81m 2 / g, the following examples and comparative examples all use the carrier), at 60 ° C equal-volume immersion containing a certain amount of H 2 PtCl 6 immersion in aqueous solution for 2 hours, dried at 100°C for 6 hours, and then fired in a muffle furnace at 500°C for 4 hours to obtain θ-Al with 0.01% Pt loading 2 o 3 carrier.

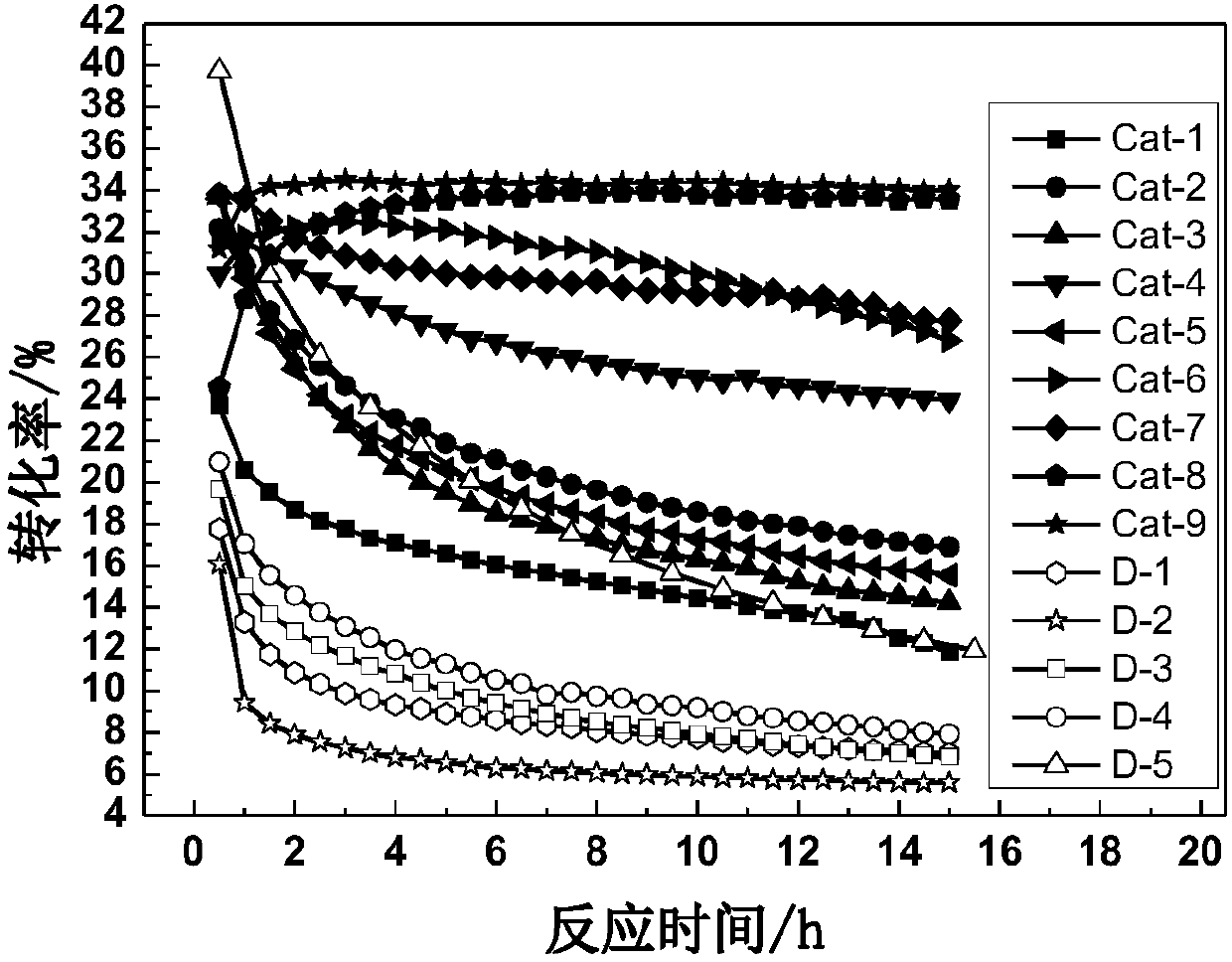

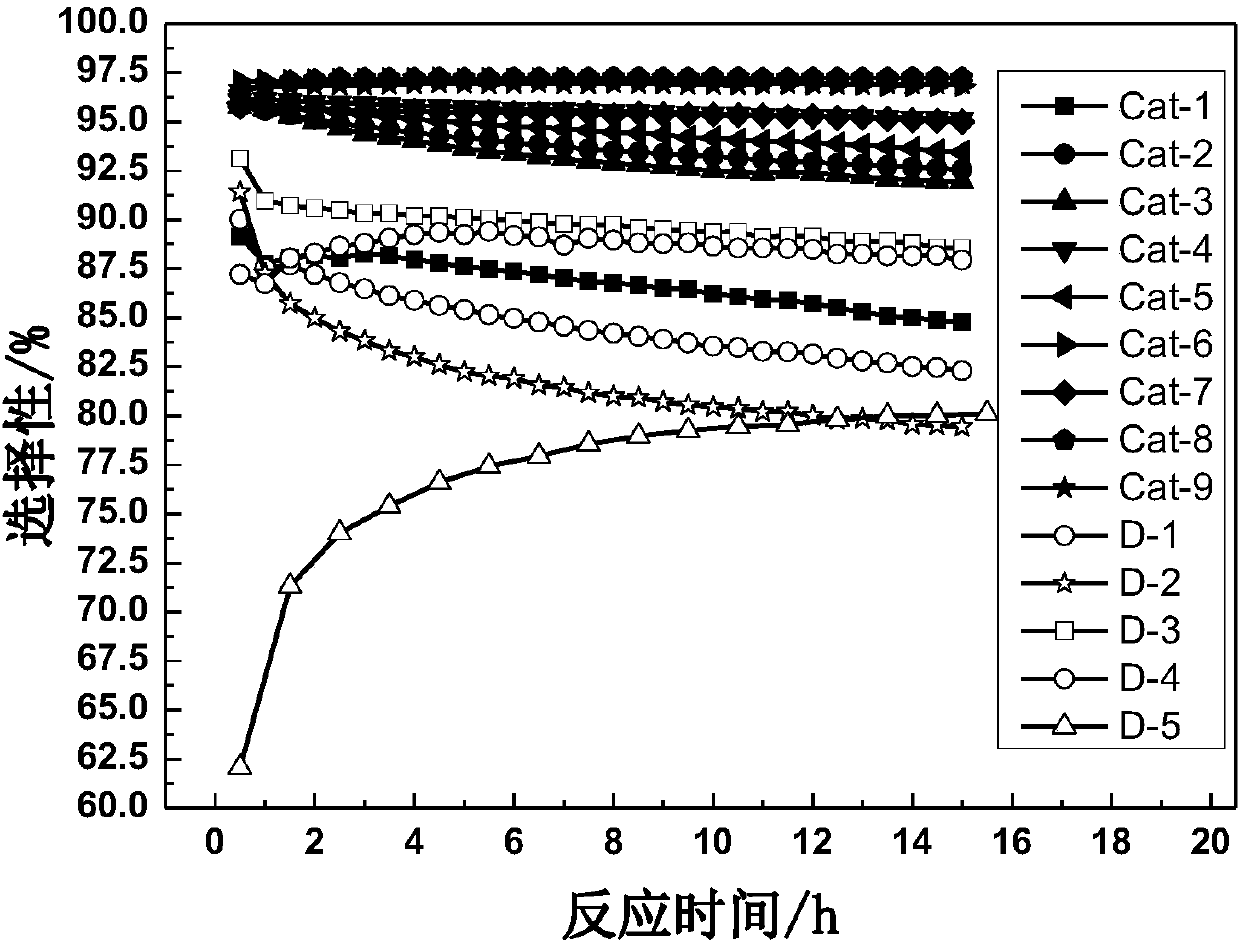

[0037] θ-Al with 0.01% Pt loading 2 o 3 Carriers with In(NO 3 ) 3 , Ga(NO 3 ) 3 The aqueous solution was mixed and impregnated for 2h, dried at 100°C for 6h, and then calcined in a muffle furnace at 600°C for 6h, H at 600°C 2 Medium reduction for 2h to obtain the catalyst. The loading amount of each component in the catalyst based on the alumina carrier is: 0.01wt% of Pt, 0.25wt% of In, and 1.0wt% of Ga, and the obtained catalyst is designated as Cat-1.

[0038] Evaluation conditions: catalyst m...

Embodiment 2

[0040] Weigh 4.0g and crush to 20-40 mesh θ-Al 2 o 3 Carrier particles (20-40 mesh particles, pore volume 0.49cm 3 / g, specific surface area 81m 2 / g, the following examples and comparative examples all use the carrier), at 60 ° C equal volume immersion containing a certain amount of KNO 3 immersion in aqueous solution for 2 hours, dried at 100°C for 6 hours, and then calcined in a muffle furnace at 500°C for 4 hours to obtain θ-Al with 0.5% K loading 2 o 3 carrier.

[0041] θ-Al with 0.5% K loading 2 o 3 carrier with H 2 PtCl 6 , In(NO 3 ) 3 , Ga(NO 3 ) 3 The aqueous solution was mixed and impregnated for 2h, dried at 100°C for 6h, and then calcined in a muffle furnace at 600°C for 6h, H at 600°C 2 Medium reduction for 2h to obtain the catalyst. The loading amount of each component in the catalyst based on alumina carrier is: 0.03wt% of Pt, 0.5wt% of K, 1.0wt% of Ga, 0.25wt% of In, and the obtained catalyst is designated as Cat-2.

Embodiment 3

[0043] Weigh 4.0g of θ-Al 2 o 3 Carrier, immersed in 20mL of a certain amount of KNO at 60°C 3 immersion in aqueous solution for 2 hours, dried at 100°C for 6 hours, and then calcined in a muffle furnace at 500°C for 4 hours to obtain θ-Al with 0.5% K loading 2 o 3 carrier.

[0044] θ-Al with 0.5% K loading 2 o 3 carrier with H 2 PtCl 6 , In(NO 3 ) 3 Immerse in an equal volume of aqueous solution for 2 hours, dry at 100°C for 6 hours, and then bake in a muffle furnace at 600°C for 6 hours. 2 Medium reduction for 2h to obtain the catalyst. The loading amount of each component in the catalyst based on the alumina carrier is: 0.03wt% of Pt, 0.5wt% of K, and 0.25wt% of In, and the obtained catalyst is designated as Cat-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com