Magnesium-based alloy

A magnesium-based alloy, weight percent technology, applied in the field of metal material processing, can solve the problems of inability to meet the requirements of thin-walled and ultra-thin 3C products, poor magnesium alloy strength, casting performance and corrosion resistance, etc. Castability, strong activity, proportion and application value improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A magnesium-based alloy of the present invention is used as a material for 3C cover products of 0.70-0.80 mm, or for casting, or as a machinable material, and its raw materials and weight percentages are:

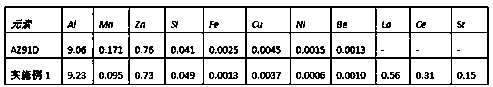

[0032] Aluminum (Al): 9.23%, Zinc (Zn): 0.73%, Manganese (Mn): 0.095%, Silicon (Si): 0.049%,

[0033] Cerium (Ce): 0.31%, Lanthanum (La): 0.56%, Strontium (Sr) 0.15%, and the balance is magnesium and impurities caused by the manufacturing process.

[0034] The composition of the magnesium-based alloy in Example 1 is compared with the composition of the commercially available AZ91D magnesium alloy as shown in Table 1.

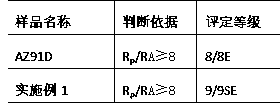

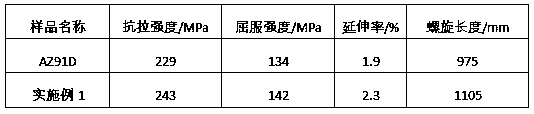

[0035] The magnesium-based alloy of embodiment 1 and the commercially available AZ91D magnesium alloy are tested for corrosion resistance, mechanical properties and casting properties, and the results are shown in chart 2 and chart 3

[0036] After testing, as shown in Table 2, the corrosion resistance of the magnesium-based alloy in Example 1 is high...

Embodiment 2

[0038] A magnesium-based alloy of the present invention is used as a material for 3C cover products of 0.60-0.70 mm, or for casting, or as a machinable material, and its raw materials and weight percentages are:

[0039] Aluminum (Al): 9.01%, zinc (Zn): 0.69%, manganese (Mn): 0.75%, silicon (Si): 0.042%, cerium 0.31%, lanthanum 0.56%, strontium 0.15%, samarium (Sm) 0.5% , and the balance is magnesium and impurities caused by the manufacturing process.

[0040] The composition of the magnesium-based alloy in Example 2 is compared with the composition of the rare earth magnesium alloy in Example 1 as shown in Table 4.

[0041] Corrosion resistance, mechanical properties and casting properties were tested on the magnesium-based alloy of Example 2 and the magnesium-based alloy of Example 1, and the results are shown in Table 5 and Table 6.

[0042] After testing, as shown in Table 5, the corrosion resistance of the magnesium-based alloy of Example 2 is higher than that of Example...

Embodiment 3

[0044]A magnesium-based alloy of the present invention is used as a material for 3C cover products of 0.45-0.60 mm, or for casting, or as a machinable material, and its raw materials and weight percentages are:

[0045] Aluminum (Al): 9.43%, zinc (Zn): 0.70%, manganese (Mn): 0.070%, silicon (Si): 0.039%, cerium 0.31%, lanthanum 0.56%, samarium 0.5%, strontium 0.15%, titanium ( Ti) 0.15%, the balance is magnesium and impurities caused by the manufacturing process.

[0046] The composition of the magnesium-based alloy in Example 3 is compared with the composition of the magnesium-based alloy in Example 2 as shown in Table 7.

[0047] The magnesium-based alloy of embodiment 3 and the magnesium-based alloy of embodiment 2 are tested for corrosion resistance, mechanical properties and casting performance, and the results are shown in chart 8 and chart 9

[0048] After testing, as shown in Table 8, the corrosion resistance of the magnesium-based alloy of Example 3 is higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com