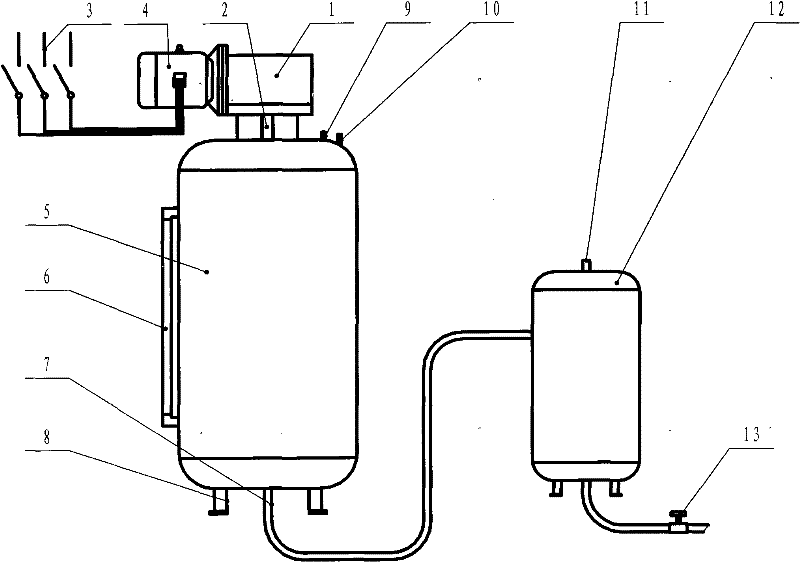

Multifunctional fermentation equipment

A fermentation equipment and multi-functional technology, which is applied in the field of compound bacteria multi-functional fermentation equipment for feed, can solve problems such as single process route, and achieve the effect of convenient use, strong activity and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

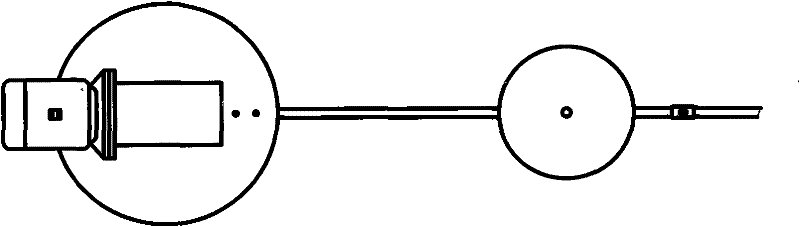

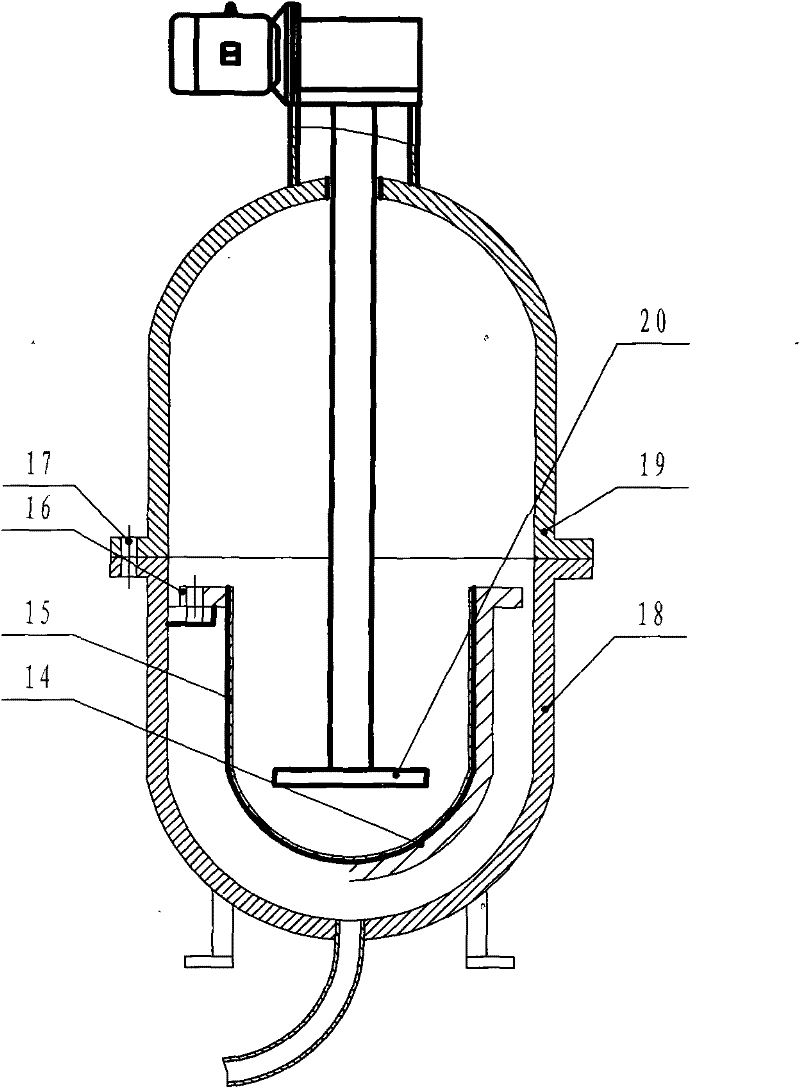

[0017] Embodiment 2, with reference to accompanying drawing, the overall structure of the second fermentation tank (12) is identical with the structure of the first fermentation tank (5), motor and speed changer are installed on the top of the upper tank body of the second fermentation tank (12), The motor is connected with an electrical switch in addition, and the speed changer (1) speed change gives the rotating speed of the stirring rod (2) more than 4 revolutions per minute.

Embodiment 3

[0018] Embodiment 3, with reference to accompanying drawing, the overall structure of the first fermentor (5) is by embodiment 1, and the second fermentor (12) changes the saccharification and fermentation filtration joint body tank into, and promptly the second fermentor (12) changes from the first The bacterium liquid that the conduit (7) of fermenter (5) transports over enters in the second fermenter (12), and the upper and lower floors are divided in the second fermenter (12) inner cavity, separated by a clapboard and / or with a clapboard. The net is separated, and the second fermentation tank (12), the lower tank body also has a bracket to support the filter screen, and there is an interlayer between the bracket filter screen and the inner wall of the lower tank to accommodate the bacterial liquid of the filter screen, and then discharge valve (13) from the bottom Discharge into storage tanks and storage cylinders. The speed changer (1) speed change gives the rotating spee...

Embodiment 4

[0019] Embodiment 4, with reference to accompanying drawing, on the top of the first fermentor (5) and the second fermentor (12), motor (4) and speed changer (1), stirring rod (2) are not installed, in two fermentors It is the fermented product that is placed statically, and the fermentation time is more than 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com