Blue-green algae sludge treatment method

A technology for sludge treatment and cyanobacteria, which is used in microbial treatment, sewage/sludge fertilizer, biological organic part treatment, etc. It can solve problems such as abnormal growth of fish, secondary pollution, and death of aquatic organisms, and improve adsorption stability. , Conducive to deodorization, the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

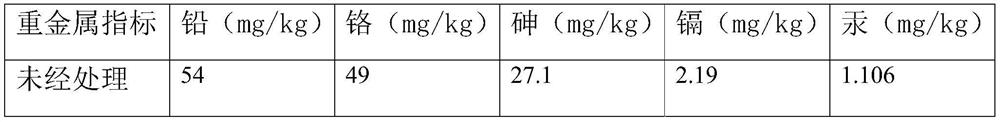

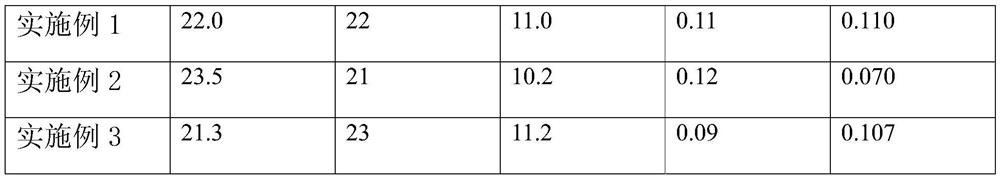

Embodiment 1

[0039] A method for treating cyanobacterial sludge, the method comprising the steps of:

[0040] 1) extract cyanobacterial sludge.

[0041] 2) Grinding hemp stalks, hemp roots, hemp branches and / or hemp leaves to obtain powdery hemp powder.

[0042] 3) stirring and mixing hemp powder, attapulgite and cyanobacterial sludge, hemp powder adsorbs heavy metals in cyanobacterial sludge, and attapulgite absorbs moisture in cyanobacterial sludge and plays a deodorizing effect; hemp powder and cyanobacterial sludge The volume ratio of mud is 0.15:1; the weight ratio of attapulgite to cyanobacterial sludge is 0.1:1.

[0043] 4) Add fermenting microorganisms to the stirring mixture in step 3) for fermentation, which is beneficial to the fermentation of cyanobacteria sludge, improves the absorption of heavy metals in the cyanobacteria sludge by the hemp powder, and interweaves the hemp powder adsorbing heavy metals to form a pile of interweaving. . Fermentation adopts stacking fermenta...

Embodiment 2

[0050] A method for treating cyanobacterial sludge, the method comprising the steps of:

[0051] 1) extract cyanobacterial sludge.

[0052] 2) Grinding hemp stalks, hemp roots, hemp branches and / or hemp leaves to obtain powdery hemp powder.

[0053] 3) stirring and mixing hemp powder, attapulgite and cyanobacterial sludge, hemp powder adsorbs heavy metals in cyanobacterial sludge, and attapulgite absorbs moisture in cyanobacterial sludge and plays a deodorizing effect; hemp powder and cyanobacterial sludge The volume ratio of mud is 0.2:1; the weight ratio of attapulgite to cyanobacterial sludge is 0.15:1.

[0054] 4) Add fermenting microorganisms to the stirring mixture in step 3) for fermentation, which is beneficial to the fermentation of cyanobacteria sludge, improves the absorption of heavy metals in the cyanobacteria sludge by the hemp powder, and interweaves the hemp powder adsorbing heavy metals to form a pile of interweaving. . Fermentation adopts stacking fermenta...

Embodiment 3

[0061] A method for treating cyanobacterial sludge, the method comprising the steps of:

[0062] 1) extract cyanobacterial sludge.

[0063] 2) Grinding hemp stalks, hemp roots, hemp branches and / or hemp leaves to obtain powdery hemp powder.

[0064] 3) stirring and mixing hemp powder, attapulgite and cyanobacterial sludge, hemp powder adsorbs heavy metals in cyanobacterial sludge, and attapulgite absorbs moisture in cyanobacterial sludge and plays a deodorizing effect; hemp powder and cyanobacterial sludge The volume ratio of mud is 0.3:1; the weight ratio of attapulgite to cyanobacterial sludge is 0.3:1.

[0065] 4) Add fermenting microorganisms to the stirring mixture in step 3) for fermentation, which is beneficial to the fermentation of cyanobacteria sludge, improves the absorption of heavy metals in the cyanobacteria sludge by the hemp powder, and interweaves the hemp powder adsorbing heavy metals to form a pile of interweaving. . Fermentation adopts stacking fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com