Paint slag treatment device

A treatment device and paint slag technology, applied in precipitation treatment, waste paint treatment, multi-stage water treatment, etc., can solve the problems of incomplete paint slag treatment, high energy consumption, large floor space, etc., and achieve no residual energy consumption , The effect of high processing efficiency and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

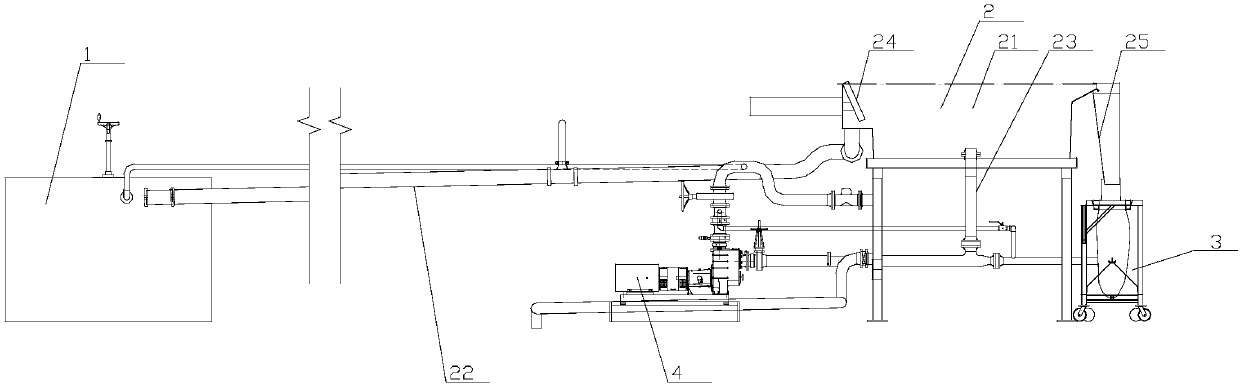

[0011] The invention is like Figure 1-2 As shown, it includes a paint slag absorbing device 1, a paint slag scraping device 2, a paint slag collecting device 3, and a dosing device 4. The paint slag scraping device 2 includes a scraping tank 21, a water inlet pipe 22, a water outlet pipe 23, The scraper device 24, the scraper drive device and the discharge hopper 25. The water inlet pipe 22 communicates with the absorption tube 13 and extends into the scraping tank 21, and the water outlet pipe 23 is connected to the bottom of the scraping tank 21 , The scraper driving device is fixedly connected to the scraping tank 21, the scraper device 24 is arranged on the upper part of the scraping tank 21, and is driven by the scraper driving device to make a horizontal reciprocating movement in the scraping tank 21; The discharge hopper 25 is fixedly connected to the side of the scraping tank 21 away from the scraper driving device;

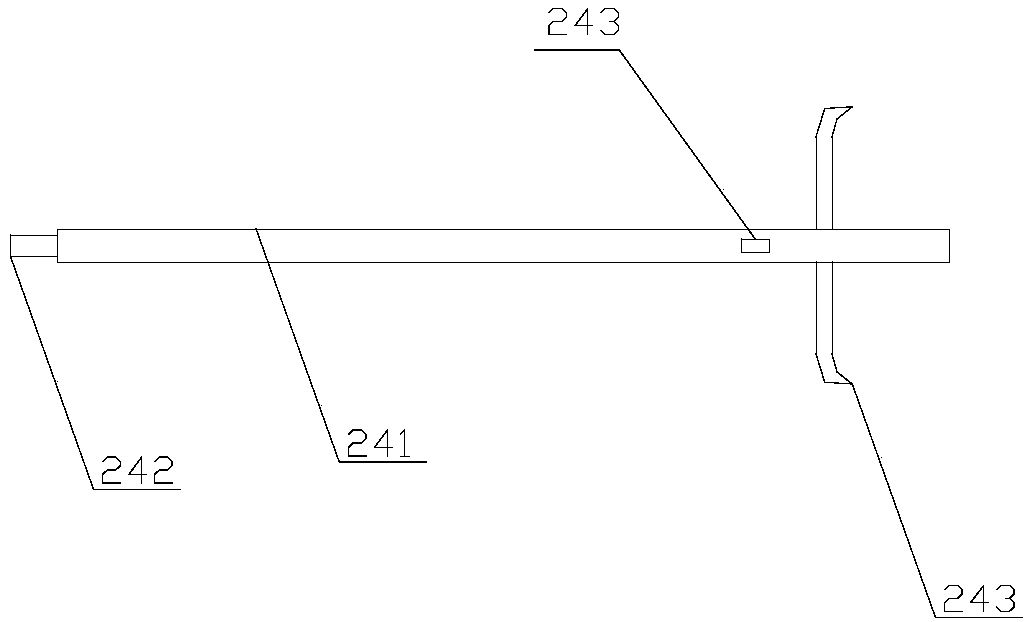

[0012] The scraper device 24 includes a hollow cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com