A method for detecting the manufacturing quality of aircraft surface based on 3D data

A technology of manufacturing quality and detection methods, which is applied in the direction of instruments, measuring devices, and optical devices, etc., can solve problems such as unsuitable for aircraft surface manufacturing quality inspection, information error flooding of rivet interest areas, and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

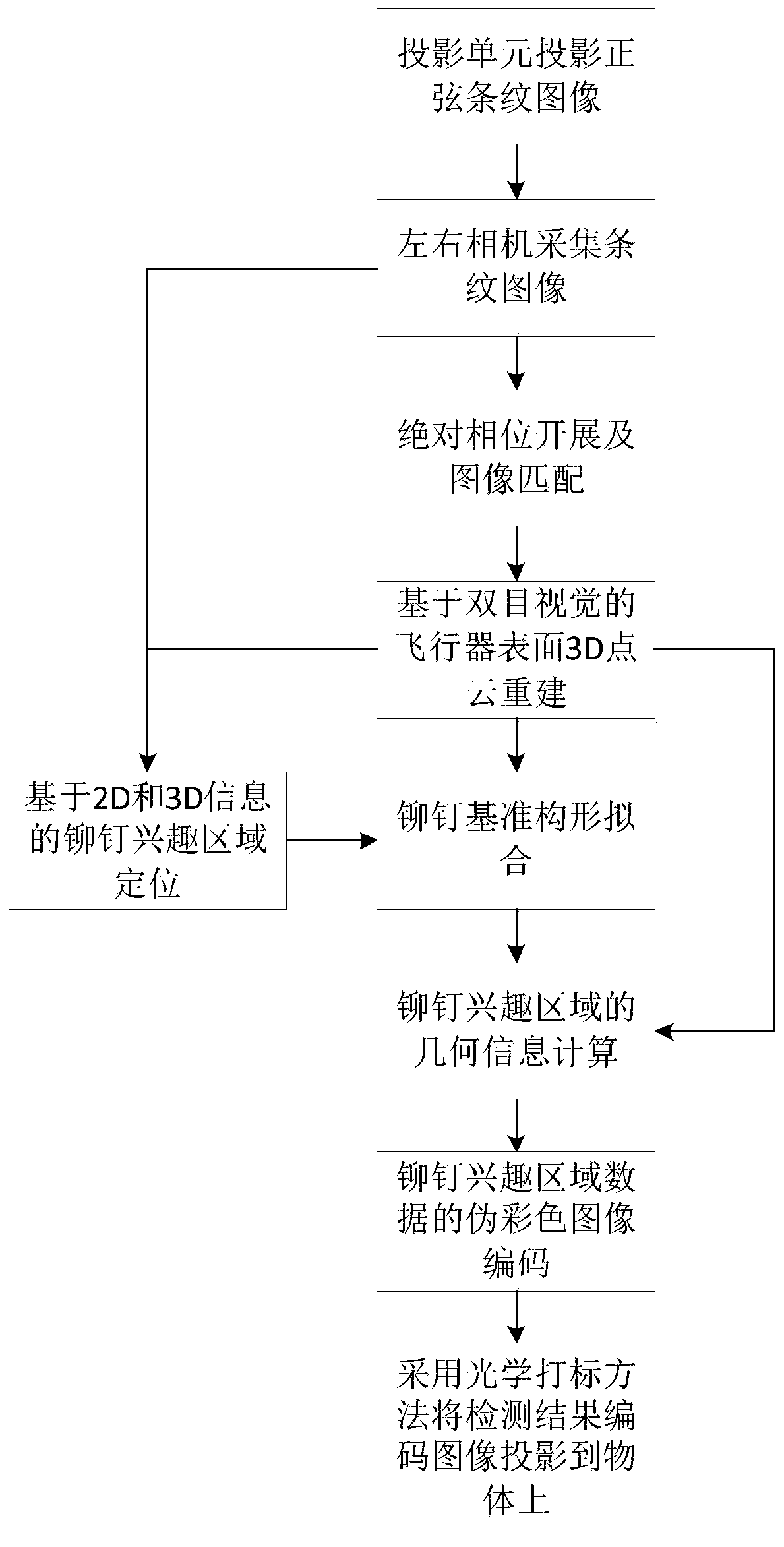

[0080] like figure 1 Shown, a kind of aircraft surface manufacturing quality inspection method based on 3D data of the present invention comprises the steps:

[0081] Use a projector to project 3 groups of 12 sinusoidal fringe images to the aircraft skin surface;

[0082] The left and right cameras collect 12 fringe images modulated by the aircraft surface;

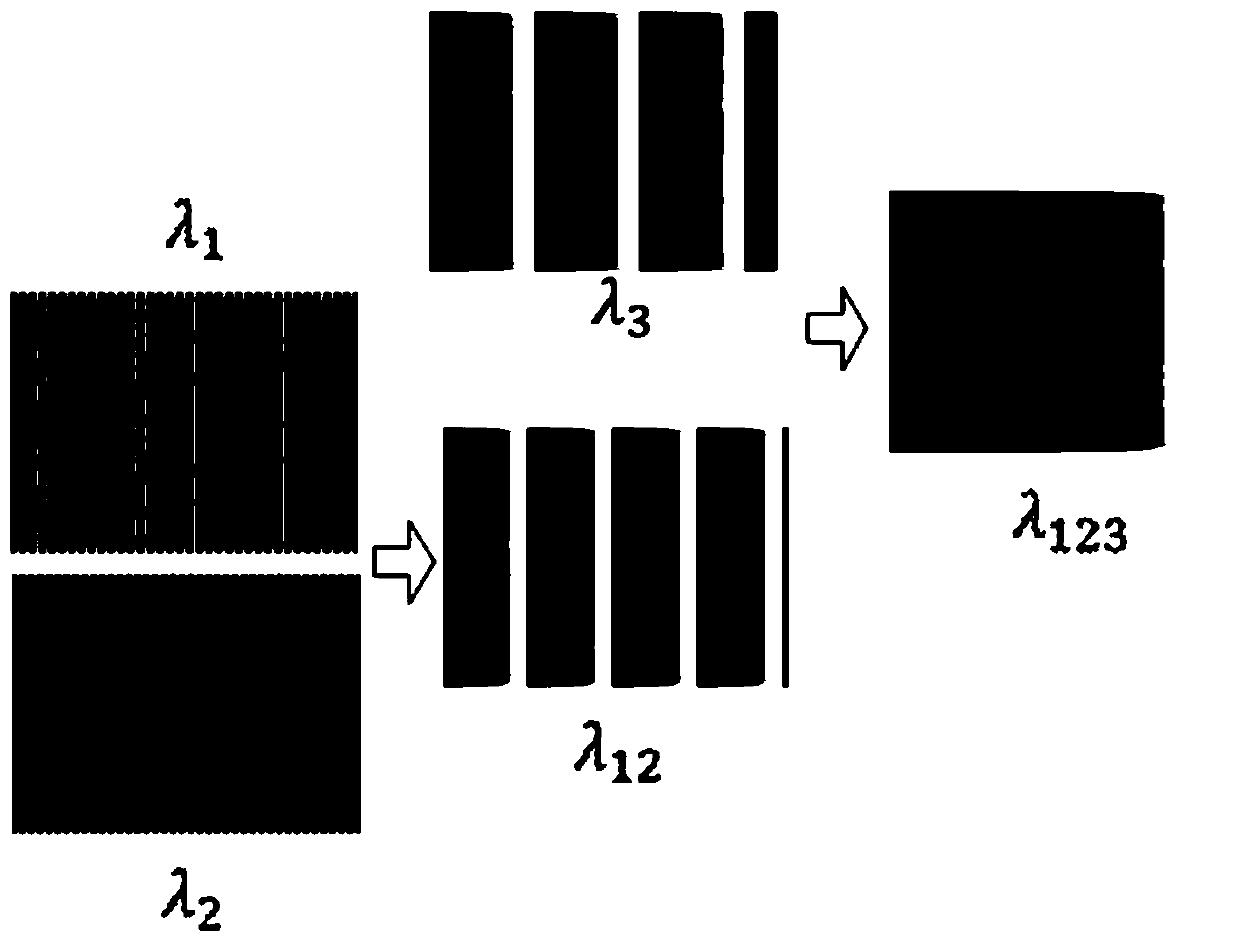

[0083] Use the image collected above to carry out phase development to obtain the absolute phase;

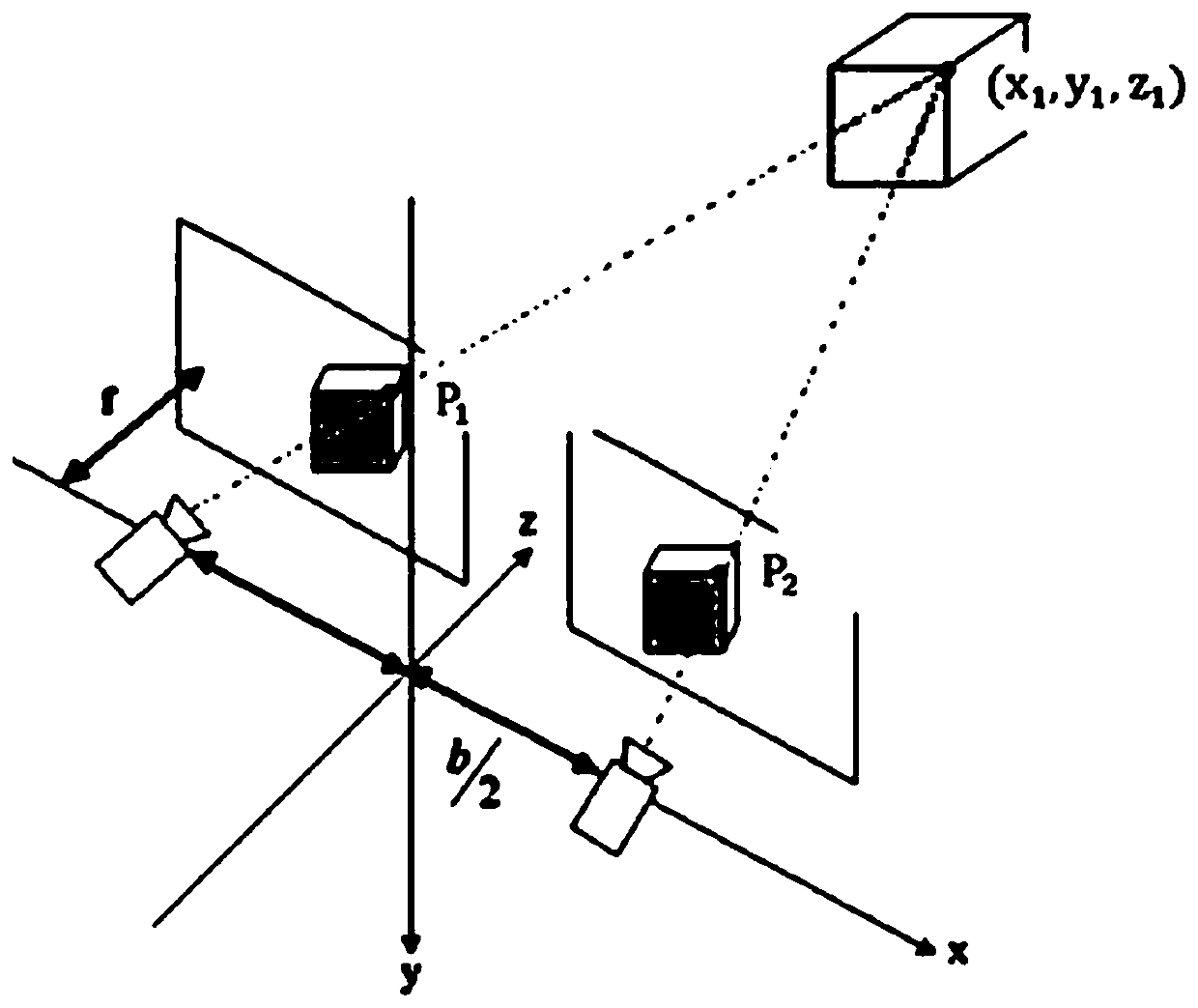

[0084] Match left and right camera images according to absolute phase and epipolar geometric constraints;

[0085] According to the image matching results and the principle of binocular vision, the 3D point cloud data model of the aircraft surface is reconstructed;

[0086] Using the two streak-free images collected by the left and right cameras, the image processing method is used to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com