Method for determining phase transformation point of low alloy steel Ar3

A low-alloy steel, phase transition point technology, applied in the investigation phase/state change, complex mathematical operations, etc., can solve time-consuming, high-cost problems, and achieve low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

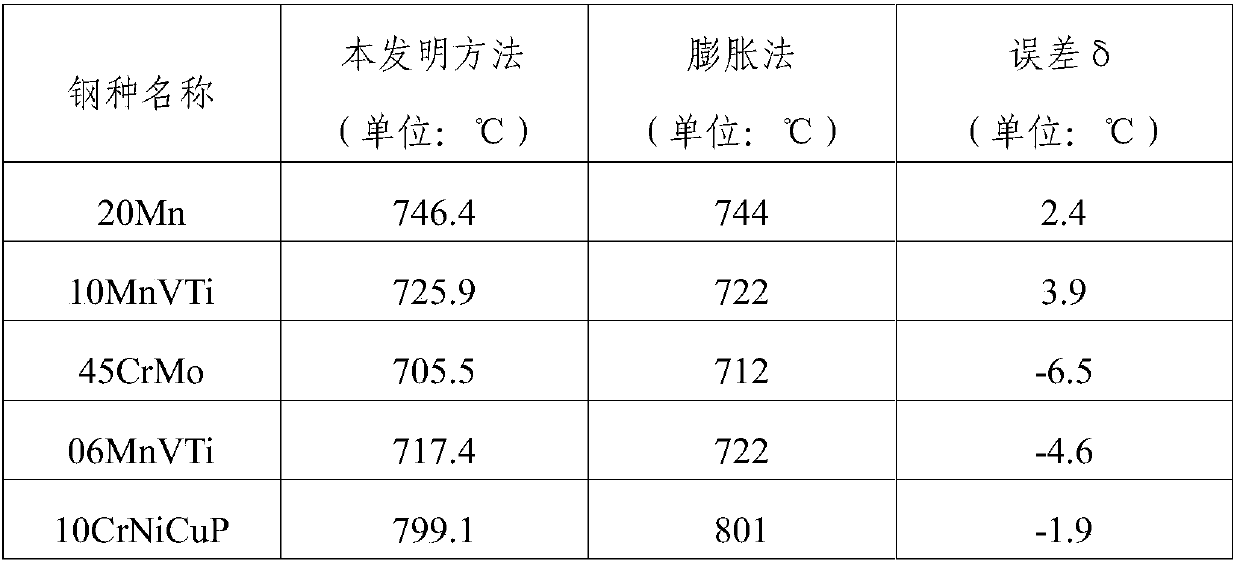

[0025] A Method for Determination of Ar in Low Alloy Steel 3 The method of phase transition point, comprises the following steps:

[0026] 1) analyze the mass percent of carbon, silicon, manganese, phosphorus, sulfur five kinds of elements in commercially available 20Mn steel, wherein, the mass percent of carbon is 0.17%, the mass percent of silicon is 0.29%, the mass percent of manganese is 0.82%, The mass percentage of phosphorus is 0.009%, and the mass percentage of sulfur is 0.016%.

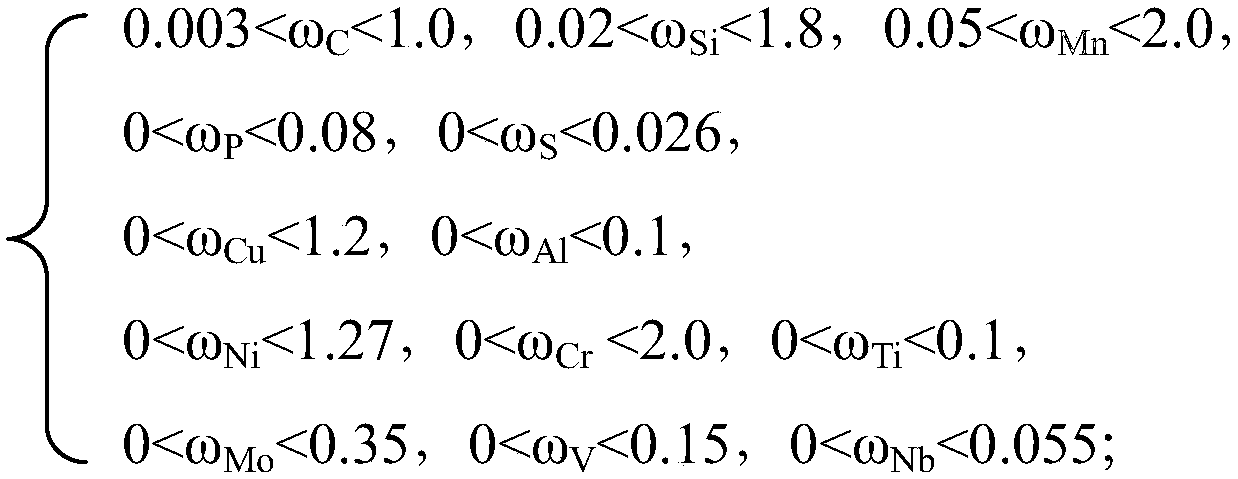

[0027] 2) The mass percent of each element obtained in step 1) is brought into the following formula:

[0028] the y Ar3 =848.87-153.73ω C +33.99ω Si -84.20ω Mn +406.54ω P -1297.37ω S -2.29ω Cu +77.31ω Al -78.54ω Ni -13.01ω Cr +461.94ω Ti +57.29ω Mo +51.36ω V -304.62ω Nb Calculate the Ar of 20Mn steel 3 Phase transition point y Ar3 is 746.4°C, where, y Ar3 Ar for steel 3 Phase transition point, unit is °C; ω C , ω Si , ω Mn , ω P , ω S , ω Cu , ω Al , ω Ni , ω Cr , ω...

Embodiment 2

[0030] A Method for Determination of Ar in Low Alloy Steel 3 The method of phase transition point, comprises the following steps:

[0031] 1) Analyze the mass percentages of seven elements of carbon, silicon, manganese, phosphorus, sulfur, titanium and alum in the commercially available 10MnVTi steel, wherein the mass percentage of carbon is 0.11%, the mass percentage of silicon is 0.28%, and the mass percentage of manganese 1.6%, the mass percentage of phosphorus is 0.023%, the mass percentage of sulfur is 0.0073%, the mass percentage of titanium is 0.038%, and the mass percentage of vanadium is 0.033%.

[0032] 2) The mass percent of each element obtained in step 1) is brought into the following formula:

[0033] the y Ar3 =848.87-153.73ω C +33.99ω Si -84.20ω Mn +406.54ω P -1297.37ω S -2.29ω Cu +77.31ω Al -78.54ω Ni -13.01ω Cr +461.94ω Ti +57.29ω Mo +51.36ω V -304.62ω Nb Calculation of Ar in 10MnVTi steel 3 Phase transition point y Ar3 is 725.9°C, where, y ...

Embodiment 3

[0035] A Method for Determination of Ar in Low Alloy Steel 3 The method of phase transition point, comprises the following steps:

[0036] 1) Analyze the mass percentages of seven elements of carbon, silicon, manganese, phosphorus, sulfur, chromium and molybdenum in commercially available 45CrMo steel, wherein the mass percentage of carbon is 0.44%, the mass percentage of silicon is 0.33%, and the mass percentage of manganese 0.78%, the mass percentage of phosphorus is 0.021%, the mass percentage of sulfur is 0.021%, the mass percentage of chromium is 1.03%, and the mass percentage of molybdenum is 0.19%.

[0037] 2) The mass percent of each element obtained in step 1) is brought into the following formula:

[0038] the y Ar3 =848.87-153.73ω C +33.99ω Si -84.20ω Mn +406.54ω P -1297.37ω S -2.29ω Cu +77.31ω Al -78.54ω Ni -13.01ω Cr +461.94ω Ti +57.29ω Mo +51.36ω V -304.62ω Nb Calculate the Ar of 45CrMo steel 3 Phase transition point y Ar3 is 705.5°C, where, y A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com