Deposition method of magnetic thin film stack, magnetic thin film stack and micro-inductance device

A technology of a magnetic film and a deposition method, applied in the field of microelectronics, can solve the problems that the magnetic film stack is not easy to be thick, the workpiece to be processed is cracked and peeled off, and it is not easy to be thick, so as to broaden the application frequency range and avoid cracking and peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order for those skilled in the art to better understand the technical solution of the present invention, the method for depositing the magnetic thin film stack and the magnetic thin film stack provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

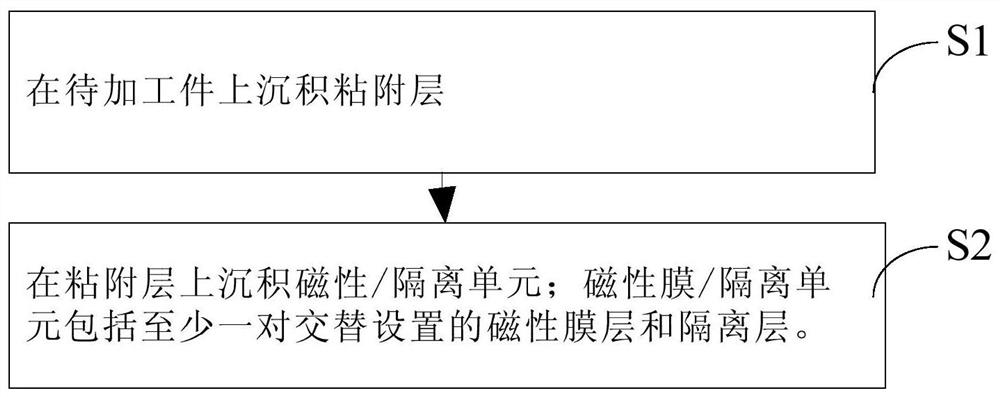

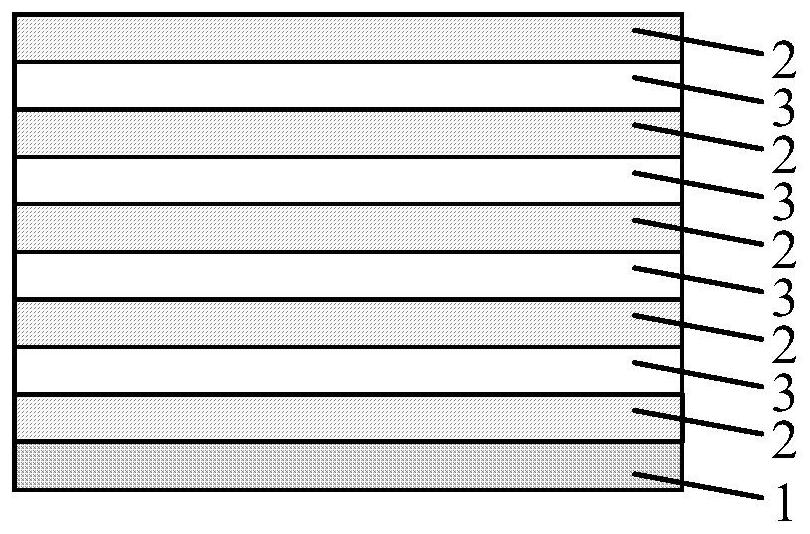

[0051] figure 2 It is a flow chart of the deposition method of the magnetic thin film stack provided by the first embodiment of the present invention. image 3 It is a structure diagram of a magnetic thin film stack obtained by using the deposition method of the magnetic thin film stack provided in the first embodiment of the present invention. Please also refer to figure 2 and image 3 , the deposition method of magnetic thin film lamination, it comprises the following steps:

[0052] S1, depositing an adhesion layer 1 on the workpiece to be processed;

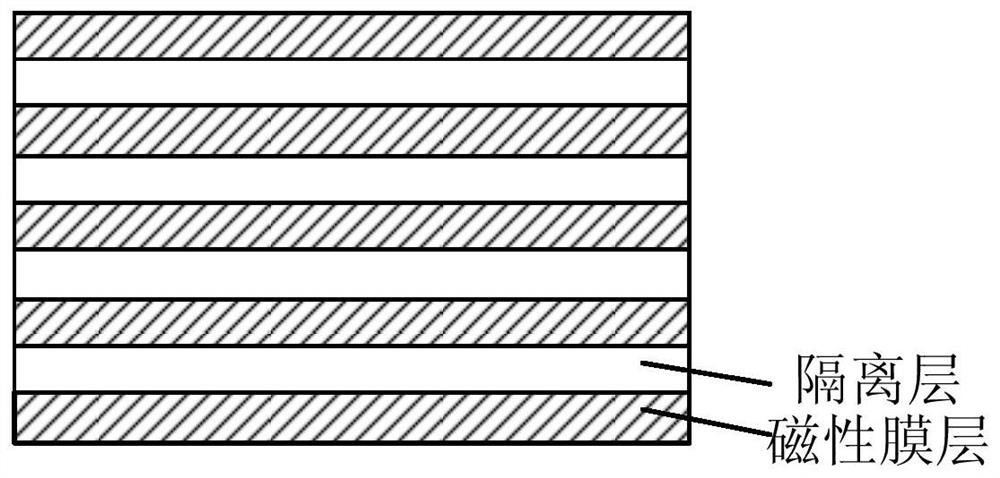

[0053] S2 , depositing a magnetic / isolation unit on the adhesion layer 1 , the magnetic / isolation unit in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com