Mulberry silkworm feeding machine

A silkworm and feed technology, which is applied in animal husbandry and other fields, can solve the problems of no special equipment, etc., and achieve the effects of getting rid of seasonal restrictions, increasing the amount of feeding, and precise feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

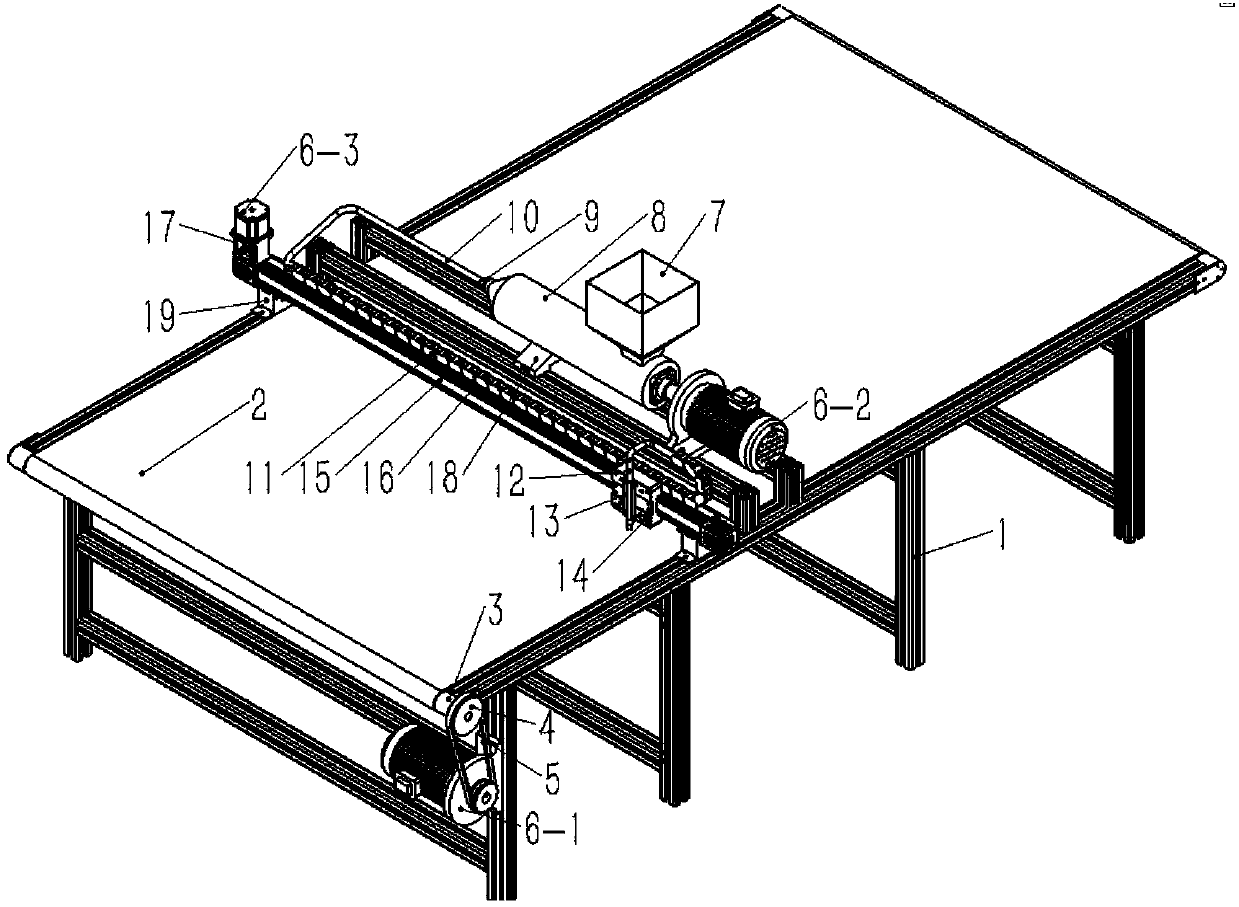

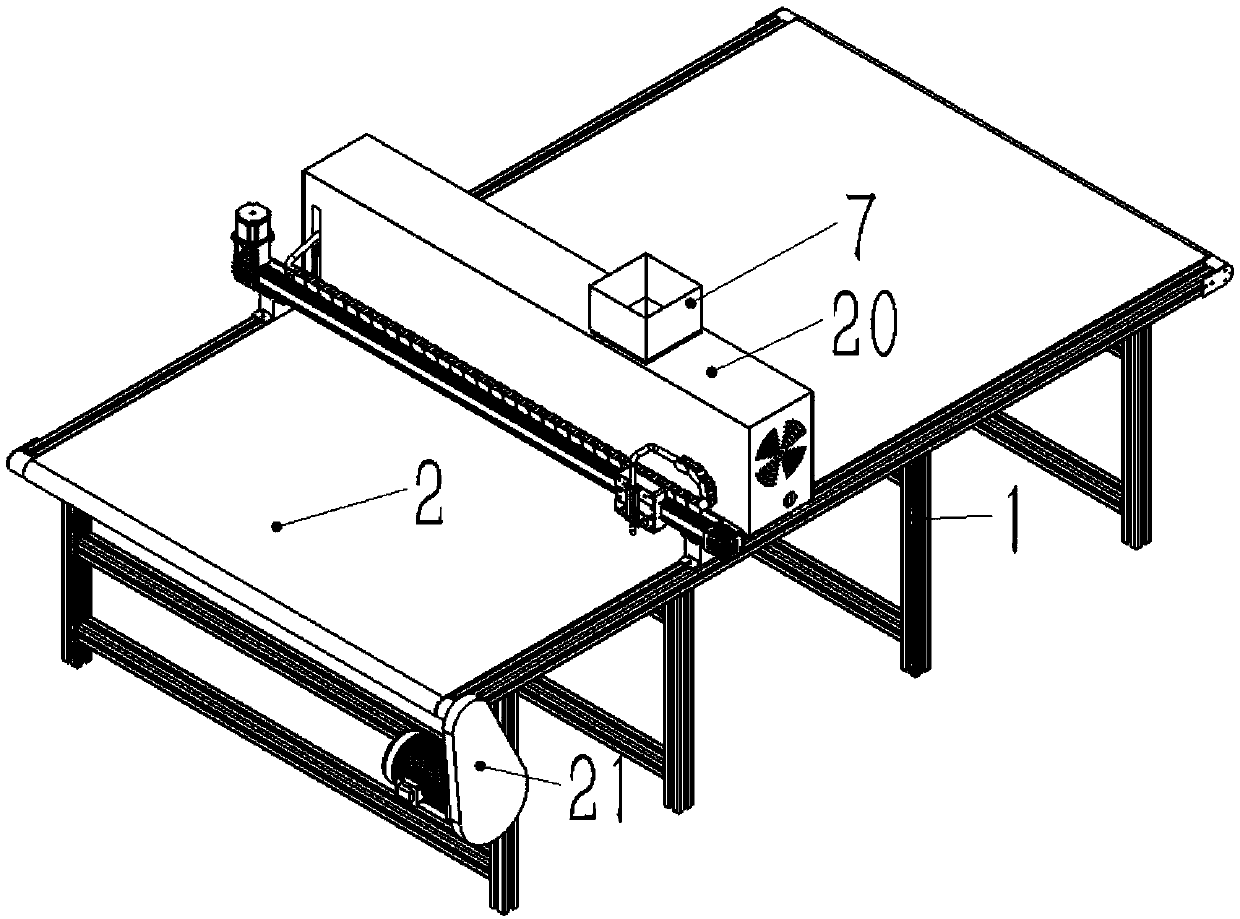

[0018] In this embodiment, industrial aluminum profiles can be used as the material to build the platform 1, which is driven by a motor.

[0019] A feeding machine for silkworms, comprising a discharging device, a feeding device, a conveying device and a stand. The platform 1 is used to support and place the discharge device, the unloading device and the conveying device;

[0020] The discharge device includes a storage bin 7, a screw conveying pipe 8, a motor 2 6-2, a hose 10, a funnel 9, a casing 20 and a support frame 18;

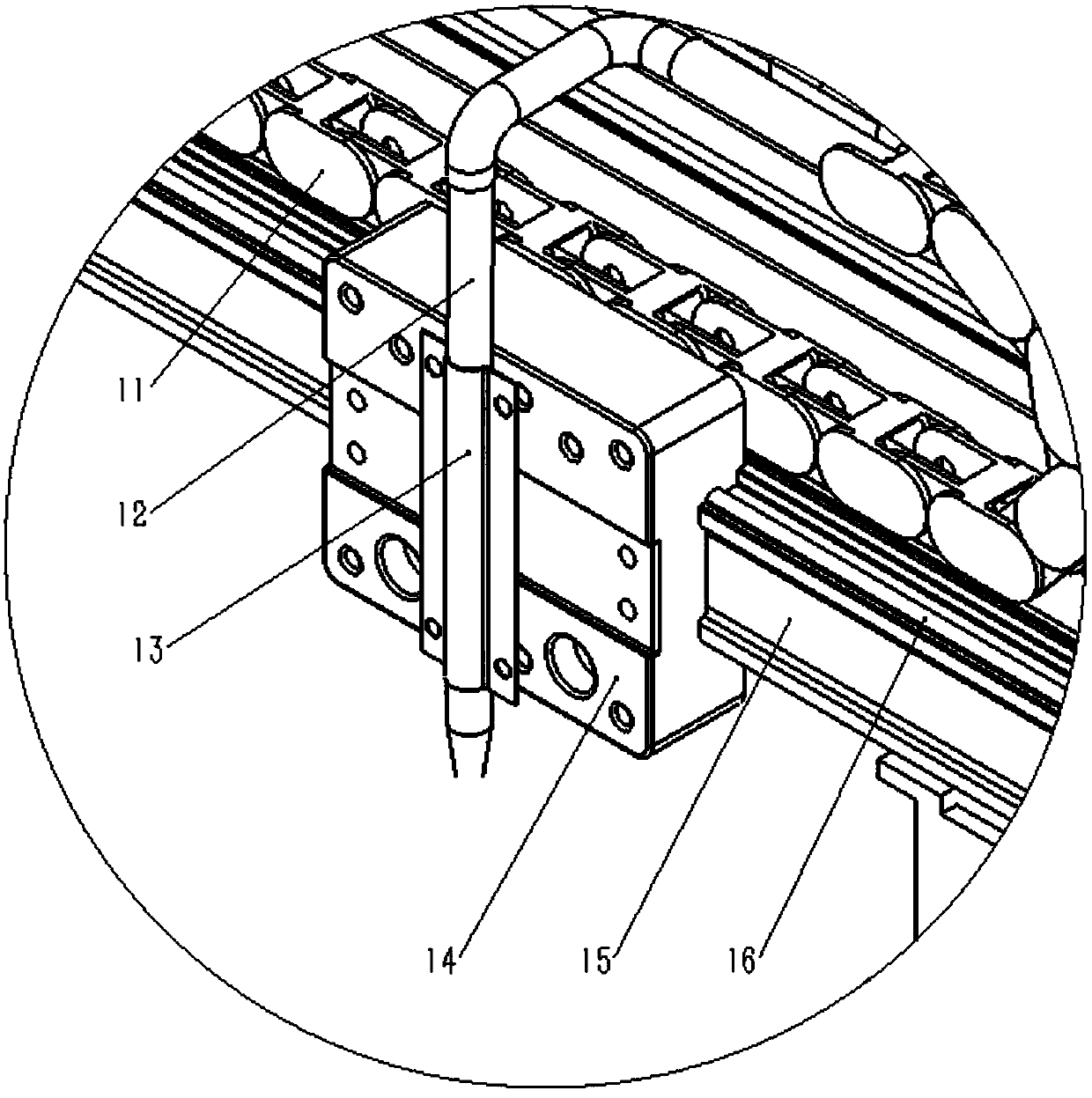

[0021] Described blanking device comprises motor three 6-1, guide rail base, synchronous belt 15, guide rail 16, slide block 14, blanking pipe 12, fixed plate 13 and tank chain 11;

[0022] The conveying device includes a motor one 6-3, a conveyor belt 2, a roller 3, a pulley 4 and a V-belt 5;

[0023] Cylinder 3 is installed on the two ends of stand 1, conveyor belt 2 is tensioned on cylinder 3, and cylinder 3 rotates, and conveyor belt 2 moves forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com