Plaster stirring kettle feeding automatic conveying device

A mud mixing tank feeding and automatic conveying device technology, which is applied in transportation and packaging, mixed material pretreatment, filtering and screening, etc., can solve the problems of low production efficiency, poor mixing effect, and different sizes of carbonate rock powder , to achieve the effect of improving the production and use effect and diversifying functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

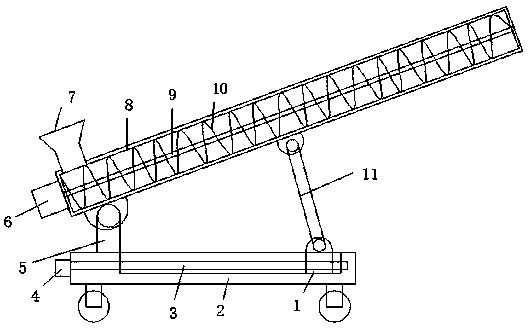

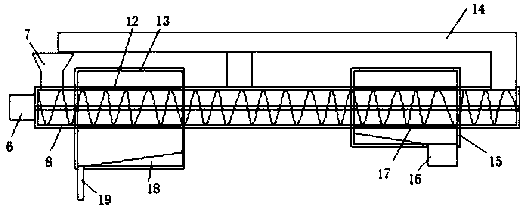

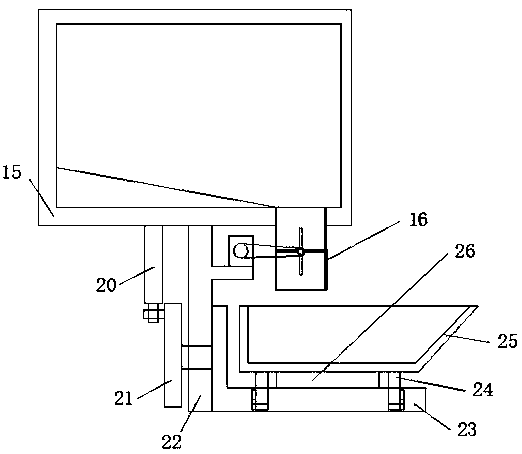

[0023]Embodiment: When in use, the first motor 4 is controlled by the controller to start, the first motor 4 drives the threaded rod 3 to rotate, the threaded rod 3 is screwed to the slider 1, and the slider 1 is driven to slide in the chute. 11 Drive the discharge height of the feeding cylinder 8 to adjust, put the carbonate rock particles into the feeding bin 7, the second motor 6 drives the feeding auger 10 to rotate through the rotating rod 9, and drives the material to continuously move to one side, first After being filtered by the first filter screen 12 on the feeding cylinder 8, very small carbonate rock particles are filtered out, enter the material guide box 13, and are discharged from the material guide pipe 19 under the action of the material guide block 18. After being filtered by the second filter screen 17 again, qualified carbonate rock particles enter the discharge box 15, and unqualified particles are introduced into the feed bin 7 through the return pipe 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com