Method for extracting gold and silver from anode mud through wet process

A technology of anode slime and wet method, applied in the field of hydrometallurgy, can solve the problems of unfriendly environment and deteriorating workshop environment, and achieve the effects of simplified process flow, efficient separation and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

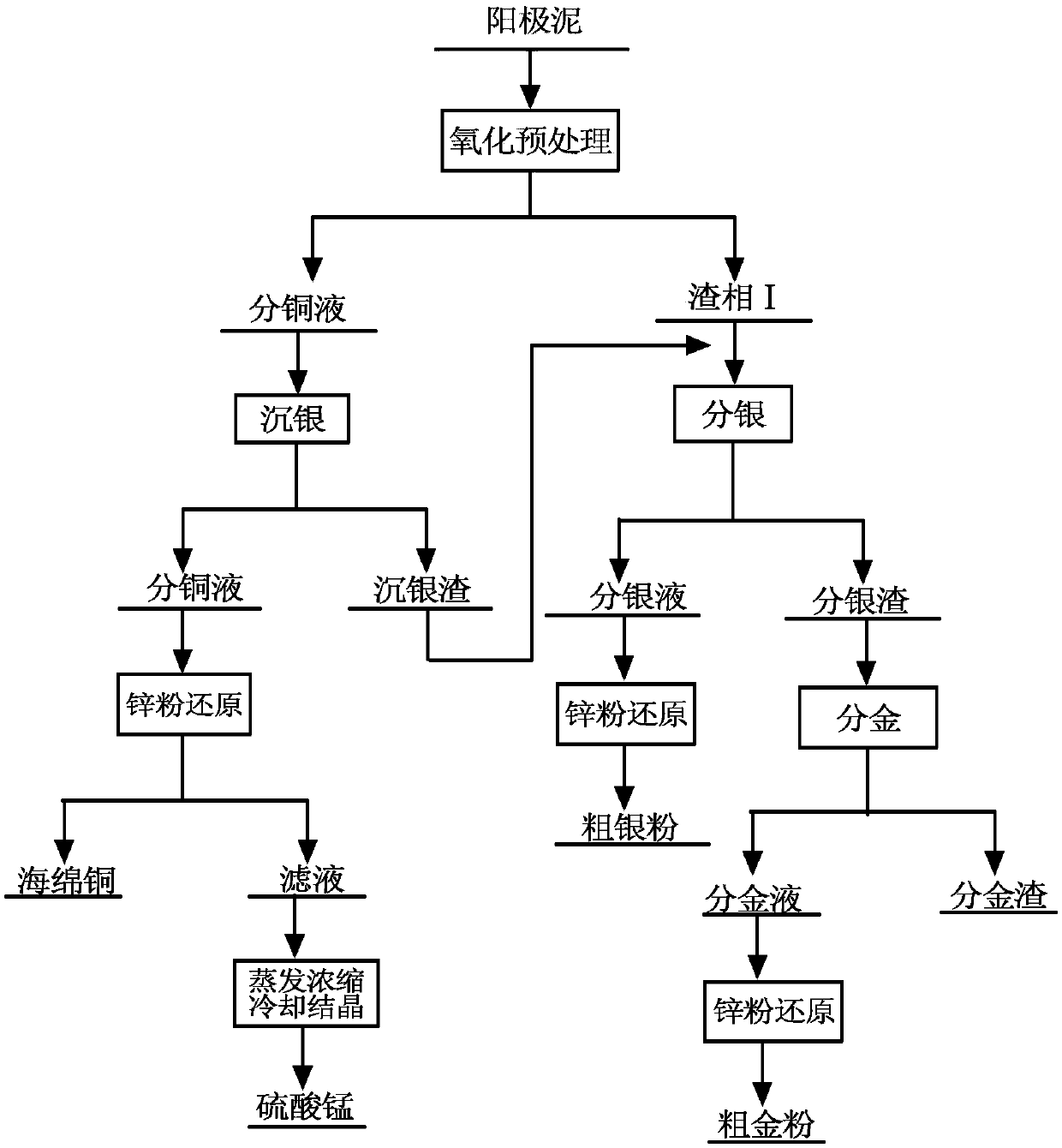

Method used

Image

Examples

Embodiment

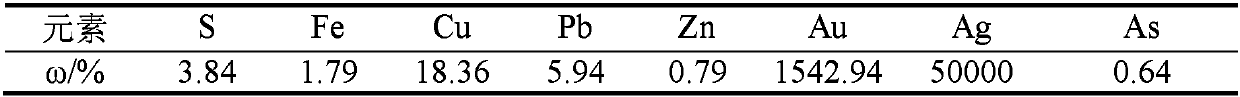

[0058] The content of some elements in the anode slime in a certain place is shown in Table 1:

[0059] Table 1. Partial element content of anode slime in a certain place (%, Au, Ag unit g / t)

[0060]

[0061] (1) Pretreatment: Take 5g of anode slime, add it to 25% dilute sulfuric acid, prepare it into a slurry according to the liquid-solid ratio of 3:1, and add 2gMnO at a mass fraction of 15% 2 , the stirring speed was set to 400rpm, the temperature was 80°C, and the leaching time was 12h. After the pretreatment, the solid-liquid separation is carried out to obtain filtrate and filter residue containing copper and manganese ions. Because part of the silver dissolves, in order to recover this part of silver, add 0.16g of sodium chloride 1.2 times the theoretical amount, and stir at room temperature for 30 minutes. . The silver chloride filter residue enters the silver separation process, and 1.13g of zinc powder, which is 1.2 times the theoretical amount, is added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com