Method for comprehensively recovering selenium, mercury, lead and silver from acid mud

A technology for recovering selenium and acid sludge, which is applied in the field of metallurgical acid sludge treatment, can solve the problems of waste of resources, failure to achieve comprehensive recovery of lead, selenium, and silver, etc., and achieve the effects of low output of waste acid, value enhancement, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

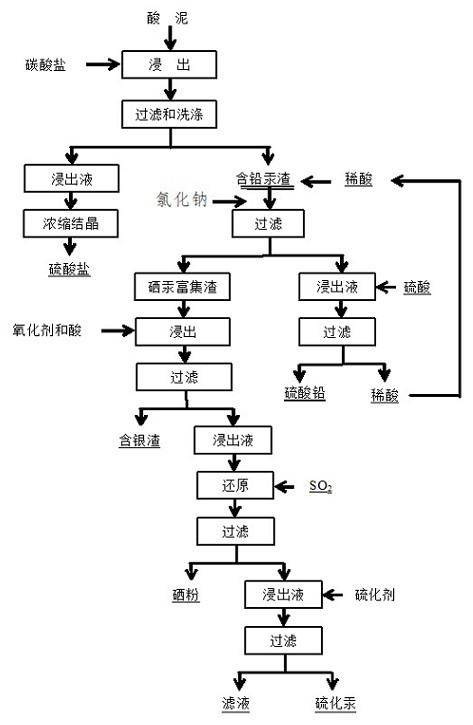

Image

Examples

Embodiment 1

[0032] Mix 1000g of acid mud with 360g of sodium carbonate, place it in a reactor for leaching, wait to be heated to 30°C, the reaction time is 3h, the rotation speed is 200rpm, stop heating after leaching, filter and mechanically stir and wash to obtain sodium sulfate leaching solution and containing Selenium, lead and mercury slag; the sulfate solution is concentrated and crystallized to obtain sulfate; the selenium, lead, mercury and silver slag and dilute nitric acid are put into the reactor for leaching, and heated to 80°C, the reaction time is 2 hours, the speed is 250rpm, and the leaching is stopped. Heating, adding sodium chloride with the same molar weight as silver, fully stirring and filtering and washing to obtain lead leachate and selenium mercury residue respectively; lead solution and dilute sulfuric acid are put into a reactor to react to generate lead sulfate precipitation and dilute nitric acid, The regenerated dilute nitric acid is returned to continue leachi...

Embodiment 2

[0034] Mix 1000g of acid mud with 360g of sodium carbonate, place it in a reactor for leaching, wait to be heated to 30°C, the reaction time is 3h, and the rotation speed is 200rpm, stop heating after leaching, filter and wash with ultrasonic radiation, and obtain sodium sulfate leaching solution and containing Selenium, lead and mercury slag; the sulfate solution is concentrated and crystallized to obtain sulfate; the selenium, lead, mercury and silver slag and dilute nitric acid are put into the reactor for leaching, and heated to 80°C, the reaction time is 2 hours, the speed is 250rpm, and the leaching is stopped. Heating, adding sodium chloride in the same amount as the molar amount of silver, stirring fully and filtering and washing to obtain lead leachate and selenium mercury residue respectively; the lead solution and dilute sulfuric acid are put into the reactor to react to form lead sulfate precipitate and dilute Nitric acid, regenerated dilute nitric acid returns to c...

Embodiment 3

[0036] Mix 1000g of acid mud with 340g of ammonium carbonate, place it in a reactor for leaching, wait to be heated to 30°C, the reaction time is 3h, the rotation speed is 200rpm, stop heating after leaching, filter and mechanically stir and wash to obtain ammonium sulfate leaching solution and containing Selenium lead mercury slag; ammonium sulfate solution is concentrated and crystallized to obtain ammonium sulfate; selenium lead mercury slag and dilute nitric acid are put into the reactor for leaching, and heated to 80°C, the reaction time is 2h, the speed is 250rpm, and the heating is stopped after leaching is completed. , after filtering and washing, lead leaching solution and selenium mercury slag were obtained respectively; lead solution and dilute sulfuric acid were put into the reactor to react to generate lead sulfate precipitate and dilute nitric acid, and the regenerated dilute nitric acid was returned to continue leaching lead slag; adding sodium hypochlorite and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com