Combined cofferdam for sludge river bed and construction method of combined cofferdam

A combination of cofferdam and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of affecting anti-seepage, weak ability to resist water erosion, and non-returning grout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

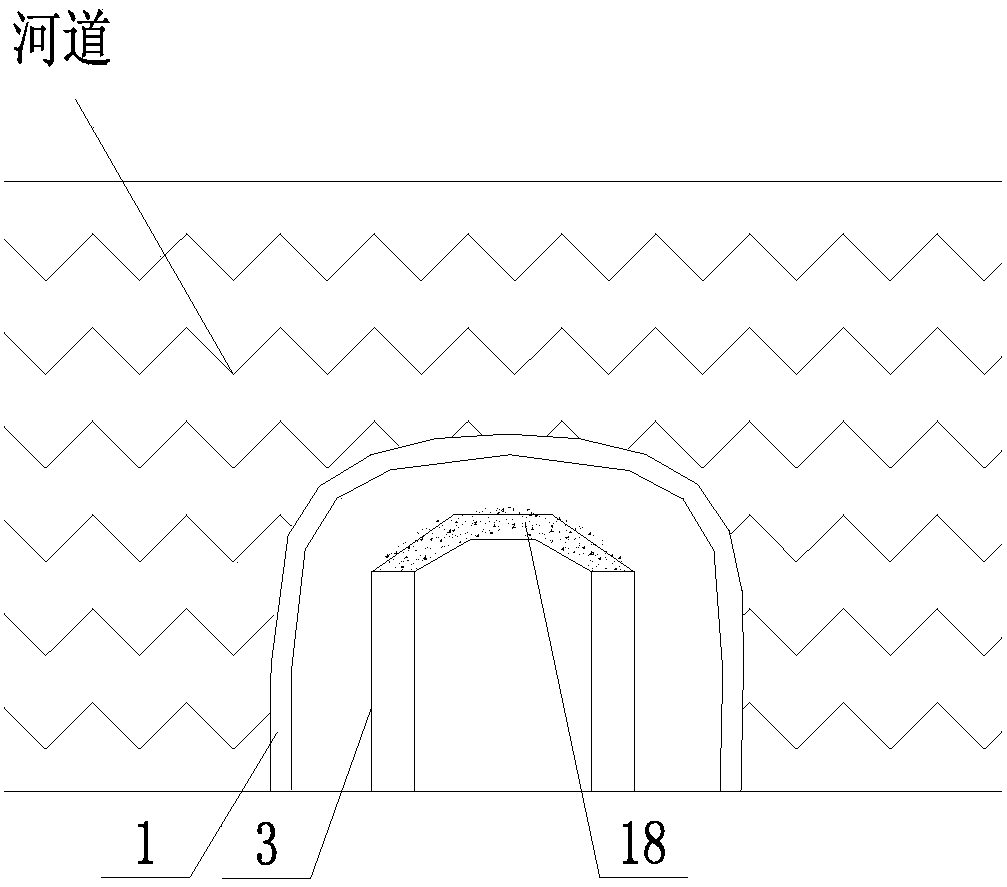

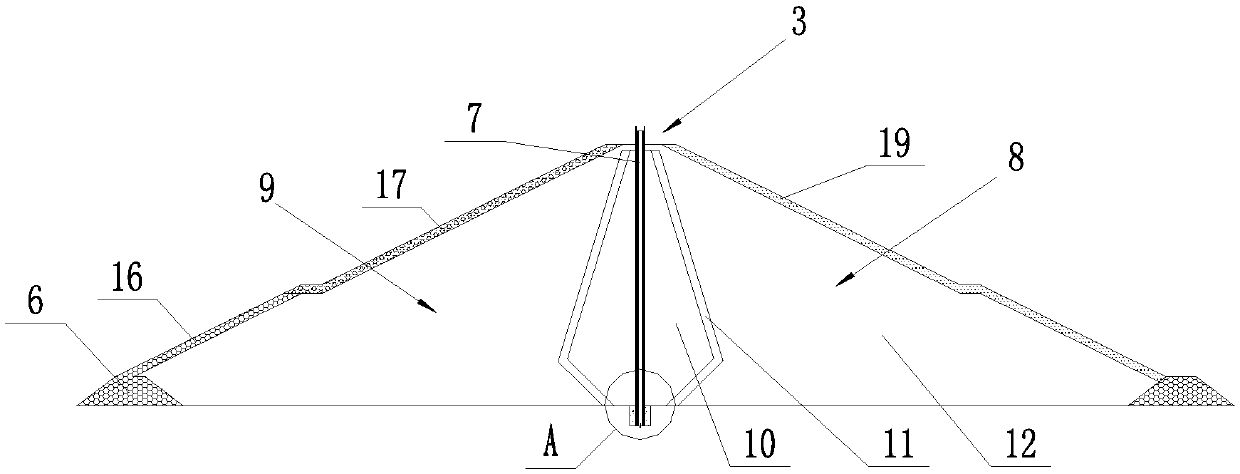

[0081] like Figure 1 to Figure 6 The shown combined cofferdam of a silt river bed includes a longitudinal concrete cofferdam arranged in the river channel and two transverse earth-rock cofferdams respectively arranged between the two ends of the longitudinal concrete cofferdam and the river bank, the longitudinal concrete cofferdam and the The river course is parallel, and the transverse earth-rock cofferdam is perpendicular to the river course;

[0082] The longitudinal concrete cofferdam includes a bottom anti-seepage structure embedded in the silt river bed and a concrete weir body 18, and the anti-seepage structure is a first anti-seepage wall 2 arranged along the length direction of the concrete weir body 18;

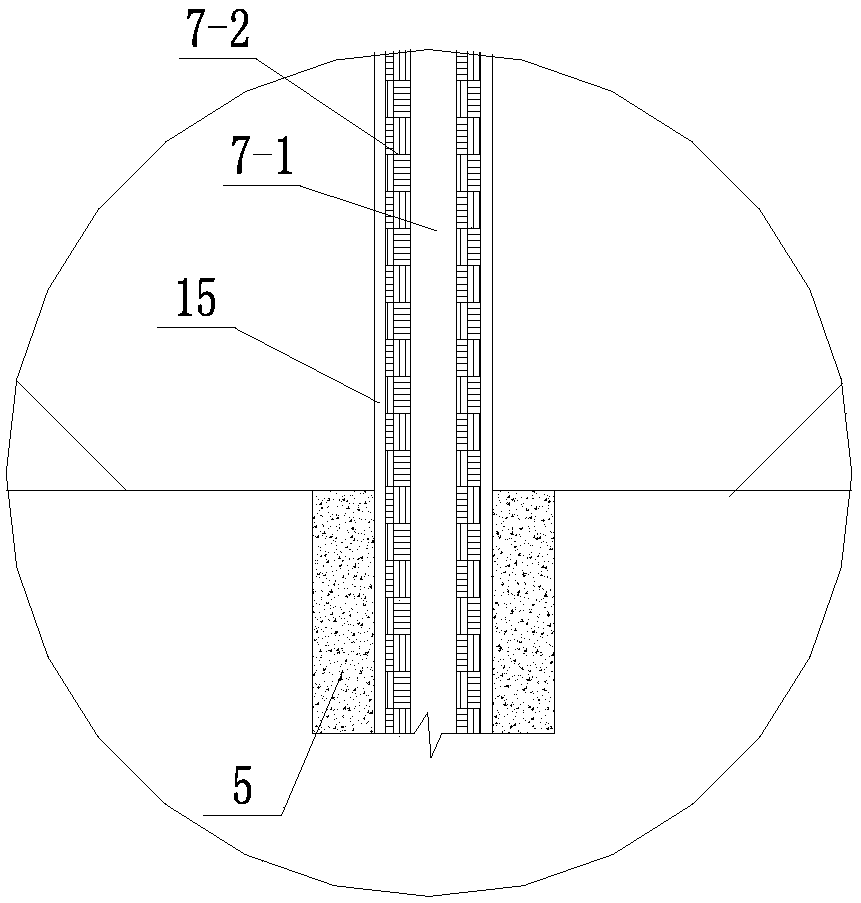

[0083] The horizontal earth-rock cofferdam includes a bottom sealing structure embedded in the silt riverbed, a vertical waterproof structure 7 and an earth-rock weir body 3; the bottom sealing structure and the vertical waterproof structure 7 are both arranged at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com