Gypsum modified rammed earth material and preparation method thereof

A gypsum modification technology, which is applied in the field of gypsum modified rammed earth materials and its preparation, can solve the problems of poor crack resistance, poor water erosion resistance, and low compressive strength, and achieve good water erosion resistance, stable performance, Excellent mechanical properties and water erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Phosphogypsum modified rammed earth material

[0023] 1. The raw materials are: red soil taken from a certain place in Kunming, Yunnan, and phosphogypsum taken from a phosphate fertilizer factory in Yunnan.

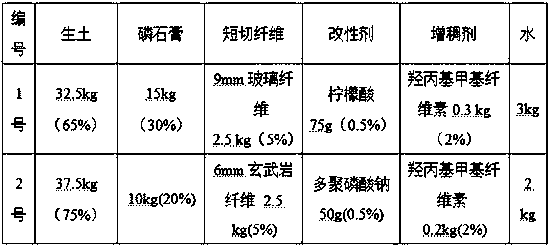

[0024] 2. The matching ratio is as follows:

[0025]

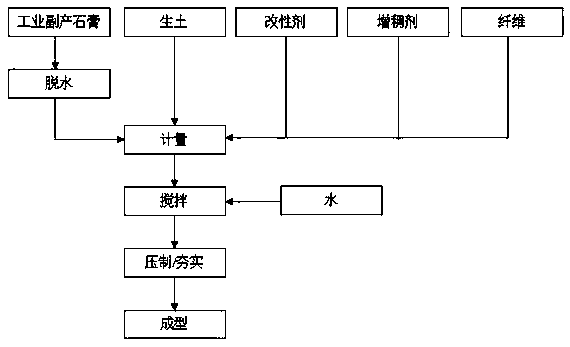

[0026] 3. Its preparation method is as follows: figure 1 As shown, the materials were prepared according to the above mixing ratio, and the phosphogypsum was dried and dehydrated at 170°C for 2 hours.

[0027] 4. Stir the above-mentioned prepared materials evenly and in a moist state.

[0028] 5. Pour the well-stirred mixture into the pre-prepared mold, tamp it layer by layer, smooth the surface, and demould after 2 hours

[0029] 6. Dry the demoulded blocks in a natural state.

[0030] After drying, the compressive strength of No. 1 phosphogypsum modified rammed earth brick can reach 3.7MPa, which can be used for general wall masonry. After drying, the compressive strength of No. 2 phosph...

Embodiment 2

[0031] Example 2: Desulfurization gypsum modified rammed earth material

[0032] 1. The raw materials are: red soil taken from a place in Kunming, Yunnan, and desulfurized gypsum taken from a power plant in Yunnan.

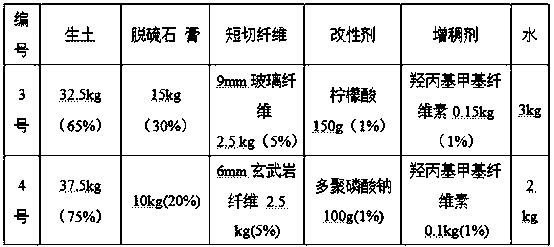

[0033] 2. The matching ratio is as follows:

[0034]

[0035] 3. Prepare materials according to the above mixing ratio, and dry and dehydrate the desulfurized gypsum at 200°C for 2 hours.

[0036] 4. Stir the above-mentioned prepared materials evenly and in a moist state.

[0037] 5. Pour the well-stirred mixture into the pre-prepared mold, tamp it layer by layer, smooth the surface, and demould after 2 hours

[0038] 6. Dry the demoulded blocks in a natural state.

[0039] After drying, the compressive strength of No. 3 desulfurized gypsum modified modified rammed earth brick can reach 4.2MPa, which can be used for general wall masonry. After drying, the compressive strength of No. 4 desulfurized gypsum modified modified rammed earth bricks can reach 3.6Mp...

Embodiment 3

[0040] Example 3: Fiber-free phosphogypsum modified modified rammed earth material

[0041] 1. The raw materials are: red soil taken from a certain place in Kunming, Yunnan, and phosphogypsum taken from a phosphate fertilizer factory in Yunnan.

[0042] 2. The matching ratio is as follows:

[0043]

[0044] 3. Prepare materials according to the above mixing ratio, and dry and dehydrate phosphogypsum at 200°C for 2 hours.

[0045] 4. Stir the above-mentioned prepared materials evenly and in a moist state.

[0046] 5. Pour the well-stirred mixture into the mold prepared in advance, carry out layered compaction, smooth the surface, and demould after 2 hours;

[0047] 6. Dry the demoulded blocks in a natural state.

[0048] After drying, the compressive strength of No. 5 desulfurized gypsum modified rammed earth bricks can reach 2.8MPa, which can be used for general wall masonry.

[0049] After drying, the compressive strength of No. 6 desulfurized gypsum modified rammed ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com