Uniform coating device for medicinal slide

A technology for coating equipment and medical glass slides, which is applied in the field of uniform coating equipment for medical glass slides, can solve the problems of low degree of mechanization, difference in the effect of coating, and high labor repeatability, so as to enhance practicability, improve practicability, The effect of improving the quality of smears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

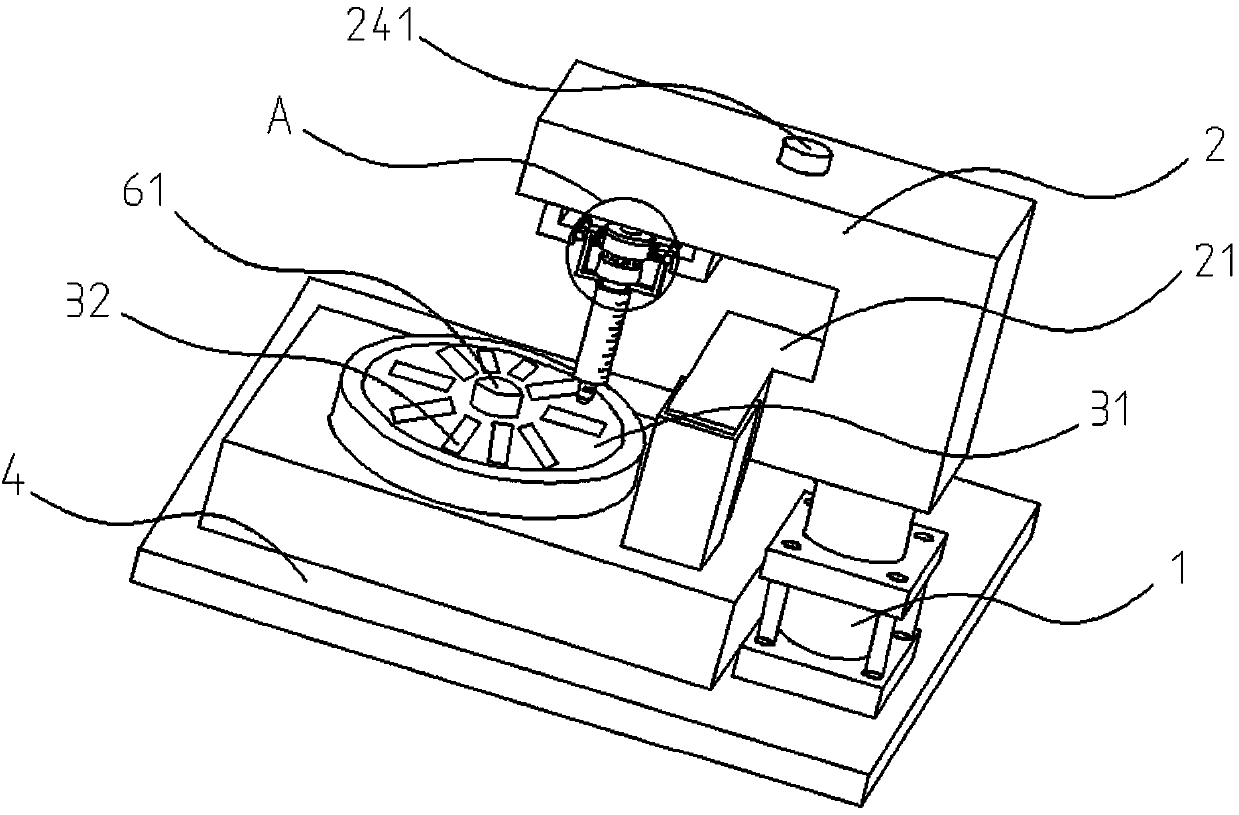

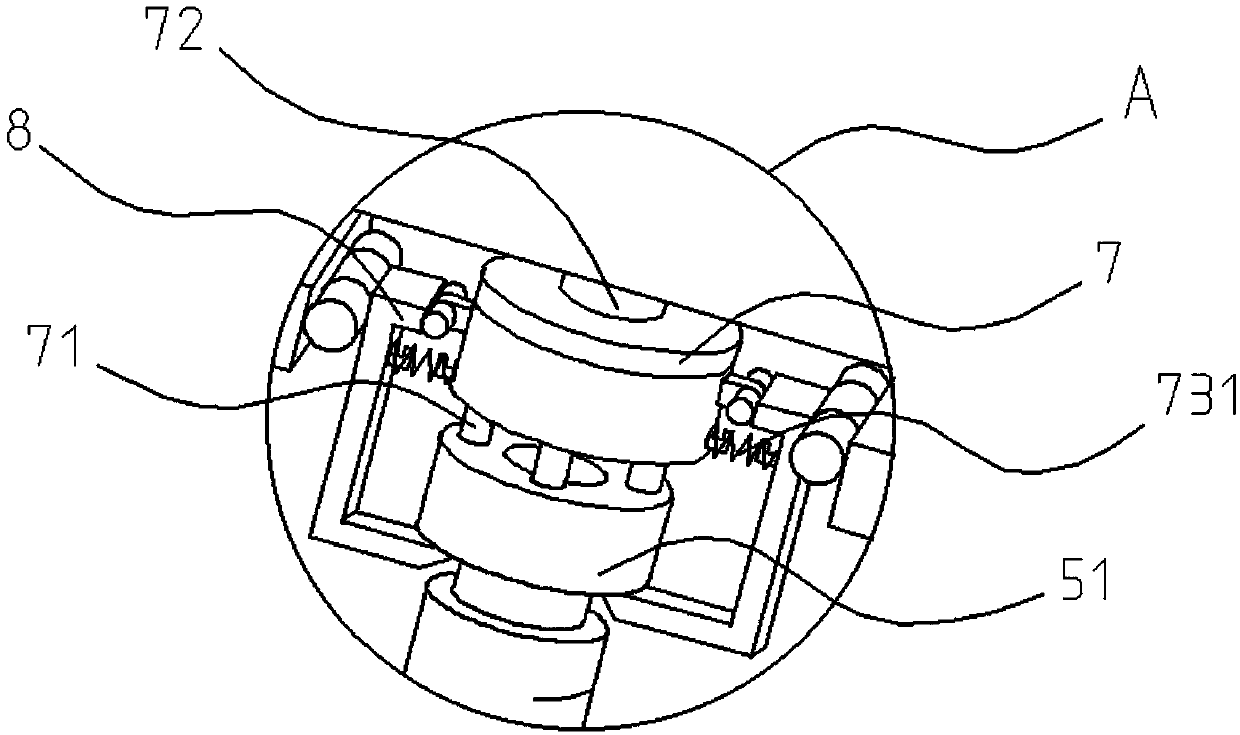

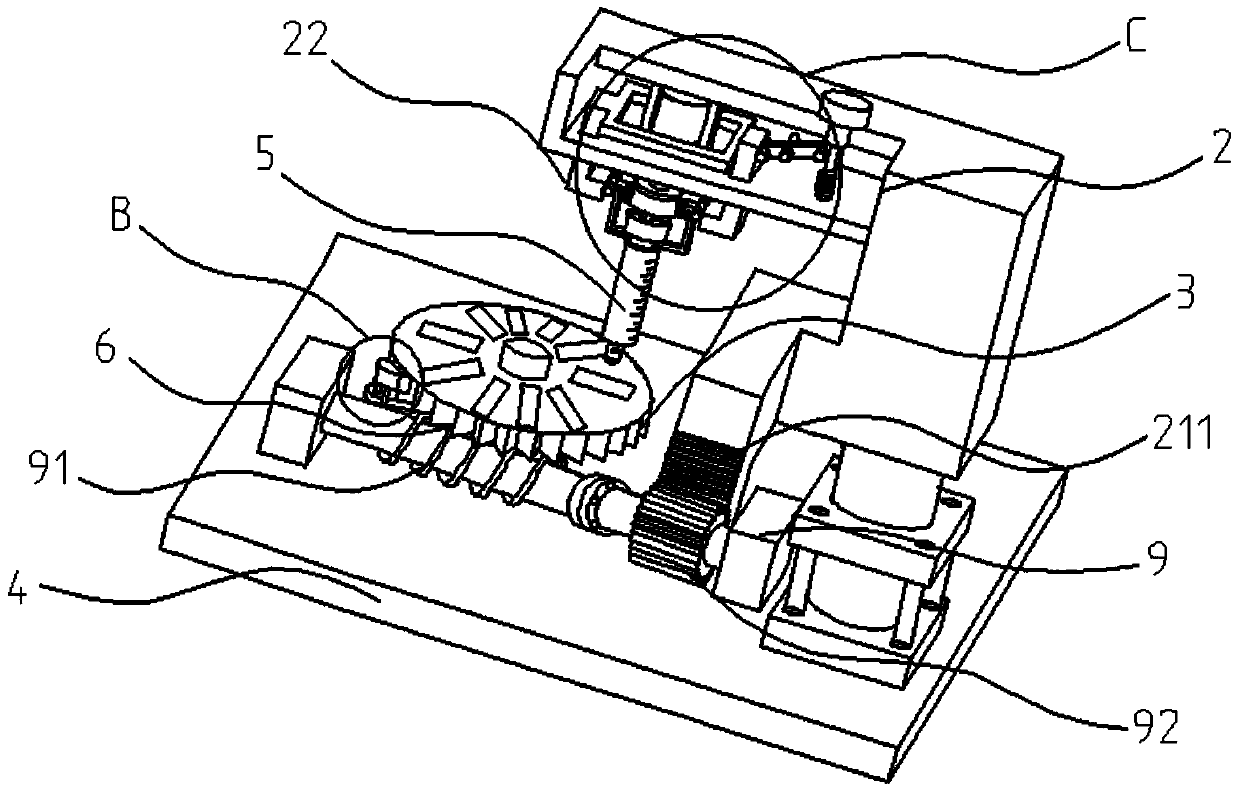

[0038] Such as Figure 1 to Figure 6As shown, a medical glass slide uniform coating equipment includes a cylinder 1, a support arm 2, a connecting rod 21, a rack 211, a positioning claw 22, a mounting frame 23, a small motor 231, a pressing rod 24, a liquid change button 241, Spring four 242, lever body 25, fulcrum column 251, connecting body 26, ratchet 3, rotating disk 31, glass slide groove 32, base 4, reagent bottle 5, bottle mouth body 51, positioning hole 511, bottle cavity 52, interlayer Plate 53, small cylindrical hole 531, support body 532, spring three 54, shock absorber 55, shock absorber block 551, stop plate 552, silica gel ball 56, diversion hole 561, hydrophilic non-woven fabric 57, worm wheel 6, Fixed shaft 61, swing rod 62, pawl 63, spring 1 64, rotating body 7, rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com