Oxygen dissolving tank and breeding water body oxygenation system

A tank and dissolved oxygen technology, applied in the field of aquaculture water aeration system, can solve the problems of waste of pure oxygen resources, inability to use soil ponds, and high cost of aquaculture, and achieve the effects of low power consumption, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

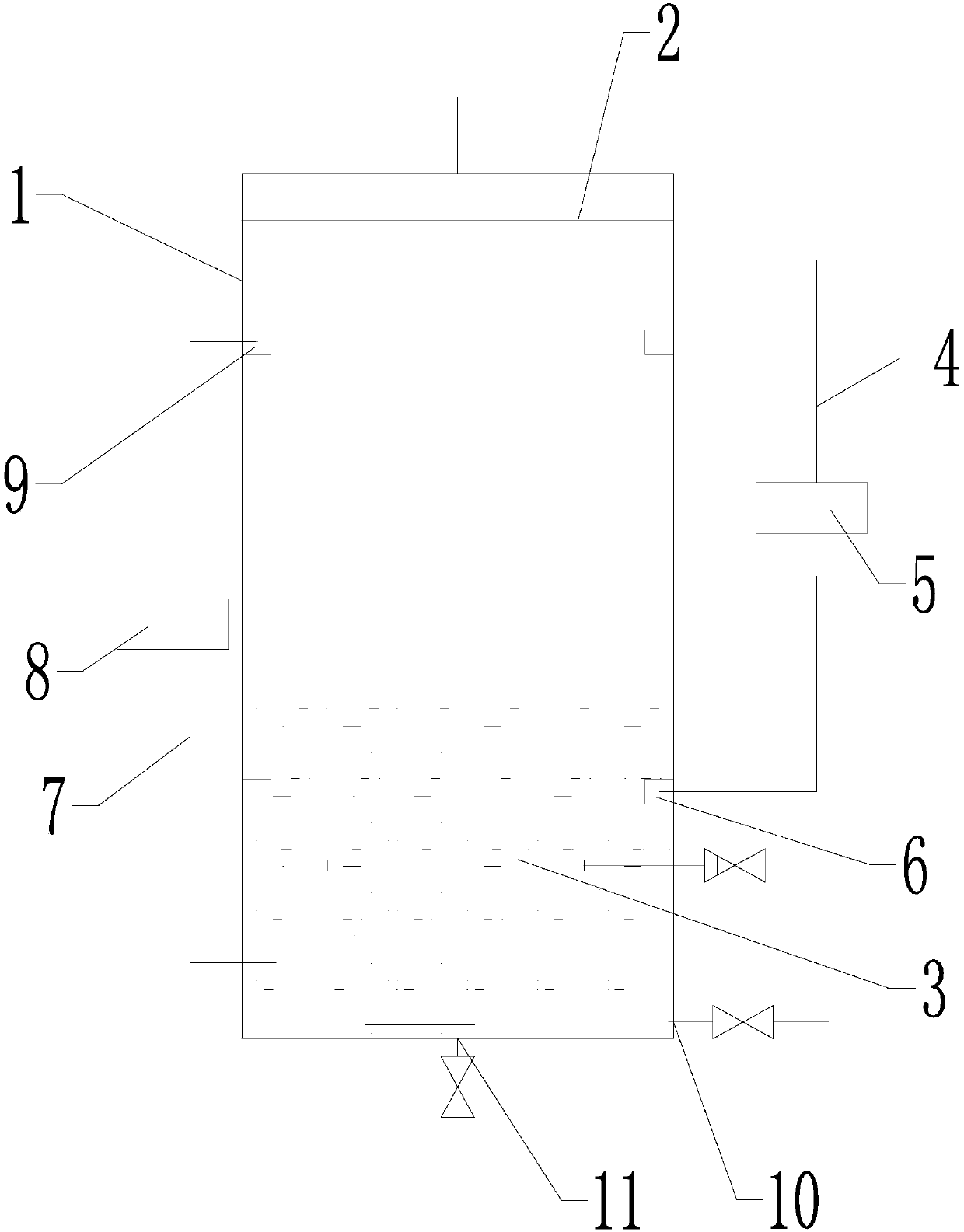

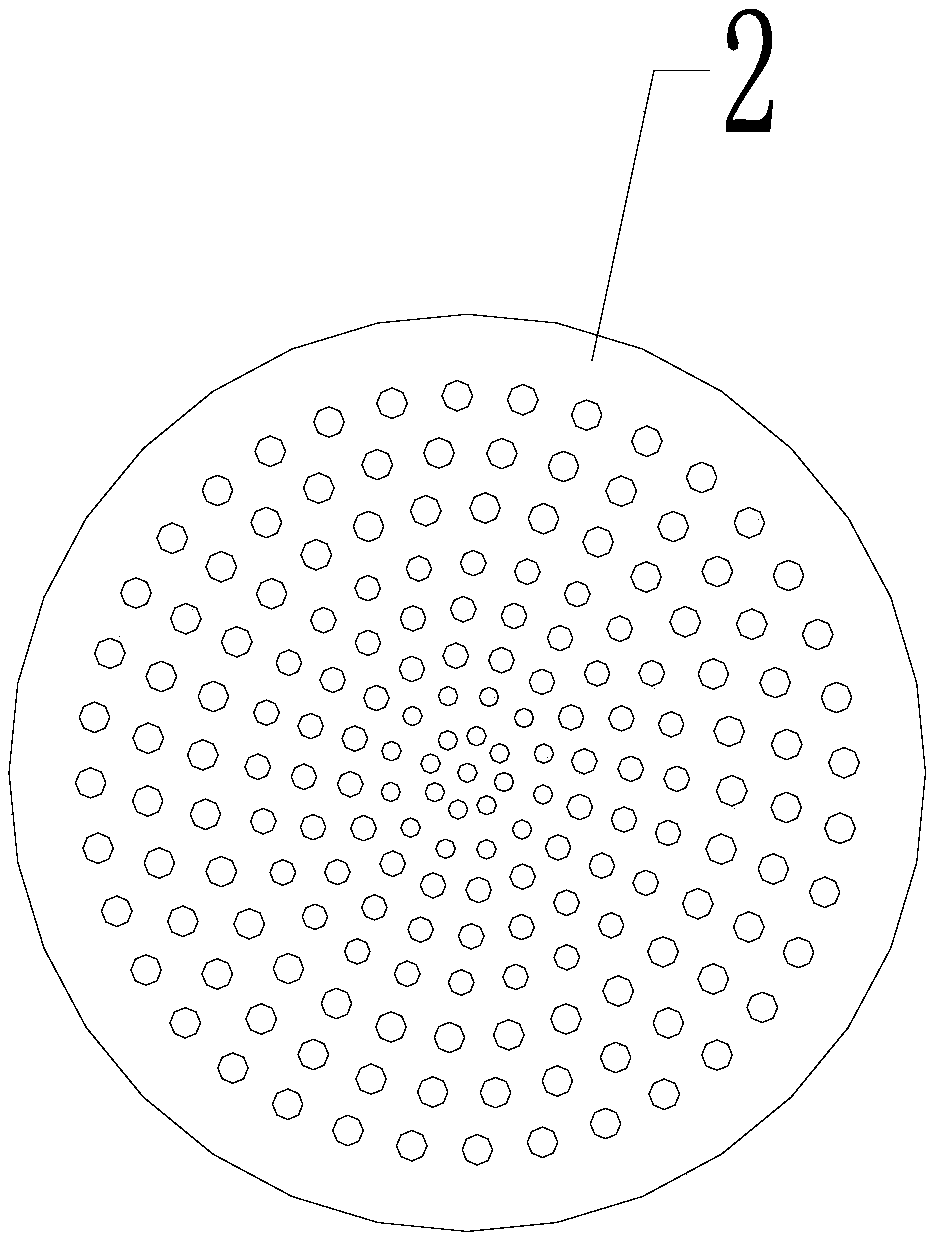

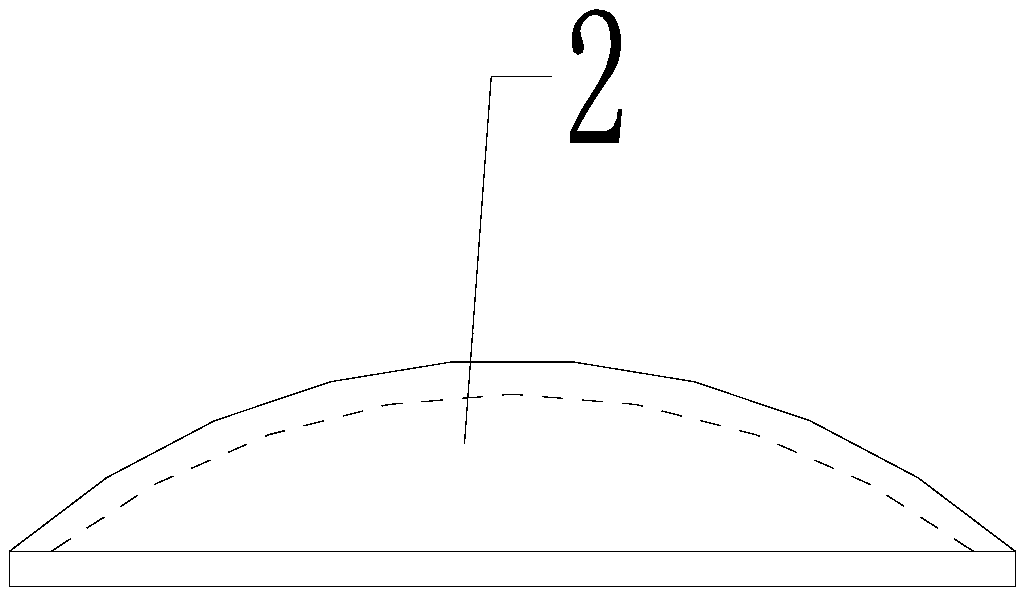

[0032] Such as figure 1 , figure 2 and image 3As shown, the present embodiment includes a closed tank body 1, on which the first water inlet located at the top of the tank body 1, the first air inlet located at the lower part of the side wall of the tank body 1 and the tank body located at 1 the water outlet 10 at the lower part of the side wall. A main water body cutter is installed in the upper part of the tank body 1, and the main water body cutter includes a second water inlet and a plurality of water outlet holes, and the second water inlet communicates with the first water inlet through a connecting pipe; or the The second water inlet is formed by the first water inlet. In this embodiment, preferably, the main water body cutter includes a circular water outlet plate 2 and an upper cover (not shown in the drawings) covering the water outlet plate 2 , and the second water inlet is located on the upper cover. The water outlet holes are located on the water outlet plat...

Embodiment 2

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, this embodiment includes the dissolved oxygen tank described in Embodiment 1, and also includes a suction pipe 12 , a water inlet pipe 14 , a water outlet pipe 16 , a water return pipe 17 , a branch pipe 15 and an oxygen source 18 . One end of the water suction pipe 12 is tee-connected with one end of the water inlet pipe 14 and one end of the branch pipe 15 , and a water pump 13 is installed on the water suction pipe 12 . The other end of the water inlet pipe 14 communicates with the first water inlet of the tank body 1 , and the other end of the branch pipe 15 is connected with one end of the water outlet pipe 16 and one end of the return pipe 17 in a three-way connection. The other end of the water outlet pipe 16 communicates with the water outlet 10 of the tank body 1 . Described oxygen source 18 is communicated with the air inlet of tank body 1 through pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com